Precision Parts Machining and Customization: Your Ideal Partner

In the field of precision parts machining and customization, finding a reliable and capable partner is crucial for the success of your projects. GreatLight CNC Machining Factory stands out as an exceptional choice, offering advanced technology, comprehensive services, and unwavering commitment to quality.

I. A Legacy of Excellence

Founded in 2011, GreatLight CNC Machining Factory has grown from a local workshop to an international precision manufacturing partner. Located in Chang’an District, Dongguan City, known as China’s “Hardware and Mould Capital,” the company operates from a modern facility covering approximately 7600 square meters, employing 150 professionals.

II. Advanced Equipment and Technology

GreatLight CNC Machining Factory is equipped with state-of-the-art machinery, including:

127 precision peripheral devices

High-precision five-axis, four-axis, and three-axis CNC machining centers

Lathes, milling machines, grinding machines, EDM machines

3D printing technologies (SLM, SLA, SLS)

This extensive equipment allows us to handle complex geometries and meet ultra-high precision requirements, ensuring that your parts are manufactured to the highest standards.

III. Comprehensive Service Portfolio

Our services encompass the entire process chain, from design to finished product:

Precision CNC machining (three-axis, four-axis, and five-axis)

CNC milling services

Die casting mold/metal die casting processing

Vacuum casting customization

Sheet metal processing customization

3D printing (stainless steel, aluminum alloy, titanium alloy, mold steel)

One-stop surface post-processing services

IV. Commitment to Quality

GreatLight CNC Machining Factory adheres strictly to ISO quality standards and holds multiple certifications:

ISO 9001:2015 for general product quality assurance

ISO 27001 for data security, essential for intellectual property-sensitive projects

ISO 13485 for medical hardware production

IATF 16949 for automotive and engine hardware component production

These certifications ensure that our processes are reliable, secure, and compliant with international standards.

V. Overcoming Common Challenges

In CNC machining, several challenges often hinder project success:

Precision inconsistencies: Our advanced equipment and stable processes ensure consistent precision, even in mass production.

Complex geometries: Our multi-axis machining capabilities allow us to handle intricate designs with ease.

Timely delivery: Our efficient workflow and comprehensive service chain ensure that your parts are delivered on time.

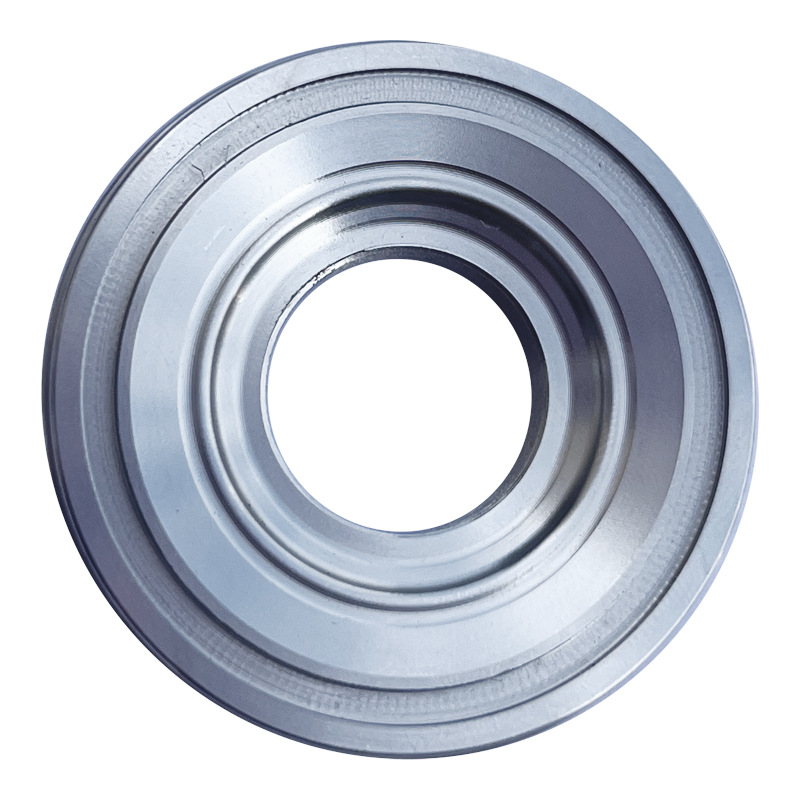

VI. Real-World Applications

GreatLight CNC Machining Factory has extensive experience in various sectors:

Automotive: Manufacturing complex engine components and structural parts.

Aerospace: Producing high-precision components for aircraft and spacecraft.

Medical: Crafting medical devices and implants with the highest precision.

Consumer Electronics: Developing innovative components for high-end electronics.

VII. Why Choose GreatLight CNC Machining Factory?

Our core advantages lie in our technical expertise, comprehensive service chain, and commitment to quality:

Technical Hard Power: State-of-the-art equipment and advanced machining technologies.

System Soft Power: Rigorous quality management systems and international certifications.

Collaborative Service Capability: Personalized solutions and exceptional customer support.

VIII. Conclusion

GreatLight CNC Machining Factory is your ideal partner for precision parts machining and customization. With our advanced technology, comprehensive services, and unwavering commitment to quality, we ensure that your projects are completed to the highest standards of precision and reliability.

For more information about our services and how we can support your projects, please visit GreatLight CNC Machining Services. Connect with us on LinkedIn for industry insights and updates.

Choose GreatLight CNC Machining Factory for your precision parts machining and customization needs.