In the intricate world of modern manufacturing, where a single micron can be the difference between success and catastrophic failure, the quest for a reliable CNC machining service is more than a procurement decision—it’s a strategic partnership that underpins the entire product lifecycle. For engineers, designers, and procurement specialists across industries from aerospace to medical devices, the definition of “reliability” extends far beyond a simple on-time delivery. It encompasses a holistic ecosystem of precision consistency, transparent communication, rigorous quality assurance, and the technical agility to navigate unforeseen challenges.

This article delves into the multifaceted pillars that constitute a truly reliable CNC machining service, moving beyond marketing claims to examine the tangible, operational foundations that separate exceptional partners from mere vendors.

H2: Deconstructing “Reliability”: Beyond the Buzzword

A reliable CNC machining service is not a single attribute but a symphony of interdependent competencies. Let’s break down its core components:

Precision Consistency: The ability to repeatedly achieve and verify the specified tolerances (e.g., ±0.001mm / 0.001 In) across the entire production run, from the first article to the thousandth part. This is the non-negotiable baseline.

On-Time Delivery Adherence: Consistent meeting of project timelines, with proactive communication regarding any potential delays. Reliability here means trust in the schedule.

Process Transparency and Communication: Providing clear, timely updates, readily sharing inspection reports (FAIR), and having engineering staff available to discuss manufacturability (DFM) feedback. A black-box process is an unreliable one.

Quality Management System (QMS) Integrity: A documented, lived, and audited system like ISO 9001:2015 that governs every step from material certification to final inspection, ensuring traceability and continuous improvement.

Problem-Solving Agility: The technical depth and resource flexibility to address unexpected issues—be it a material anomaly, a tooling challenge, or a last-minute design change—without compromising on the core deliverables.

Supply Chain Resilience: Robust management of raw material sourcing and inventory to buffer against market fluctuations and ensure production stability.

H3: The High Cost of Unreliability: Risks You Cannot Afford

Partnering with a service that lacks true reliability exposes your project to significant, often cascading risks:

Project Timeline Collapse: Delayed parts stall assembly lines, delay product launches, and incur massive opportunity costs.

Quality Escapes and Field Failures: Inconsistent precision can lead to part non-conformance, assembly issues, or—in critical applications like medical or automotive—catastrophic product failures, resulting in recalls, liability, and brand damage.

Hidden Costs Rework and Scrap: Unreliable processes generate waste. The costs of re-machining, scrapped material, and expedited shipping to recover lost time quickly erode any initial price savings.

Engineering Resource Drain: Constant firefighting, clarifying specifications, and managing supplier issues divert your engineering team from core R&D and innovation work.

H2: The Pillars of a Truly Reliable CNC Machining Partner

Identifying a partner that embodies these principles requires looking at concrete capabilities. Here is what defines the operational backbone of reliability.

H4: 1. Technological Foundation: The Machinery of Precision

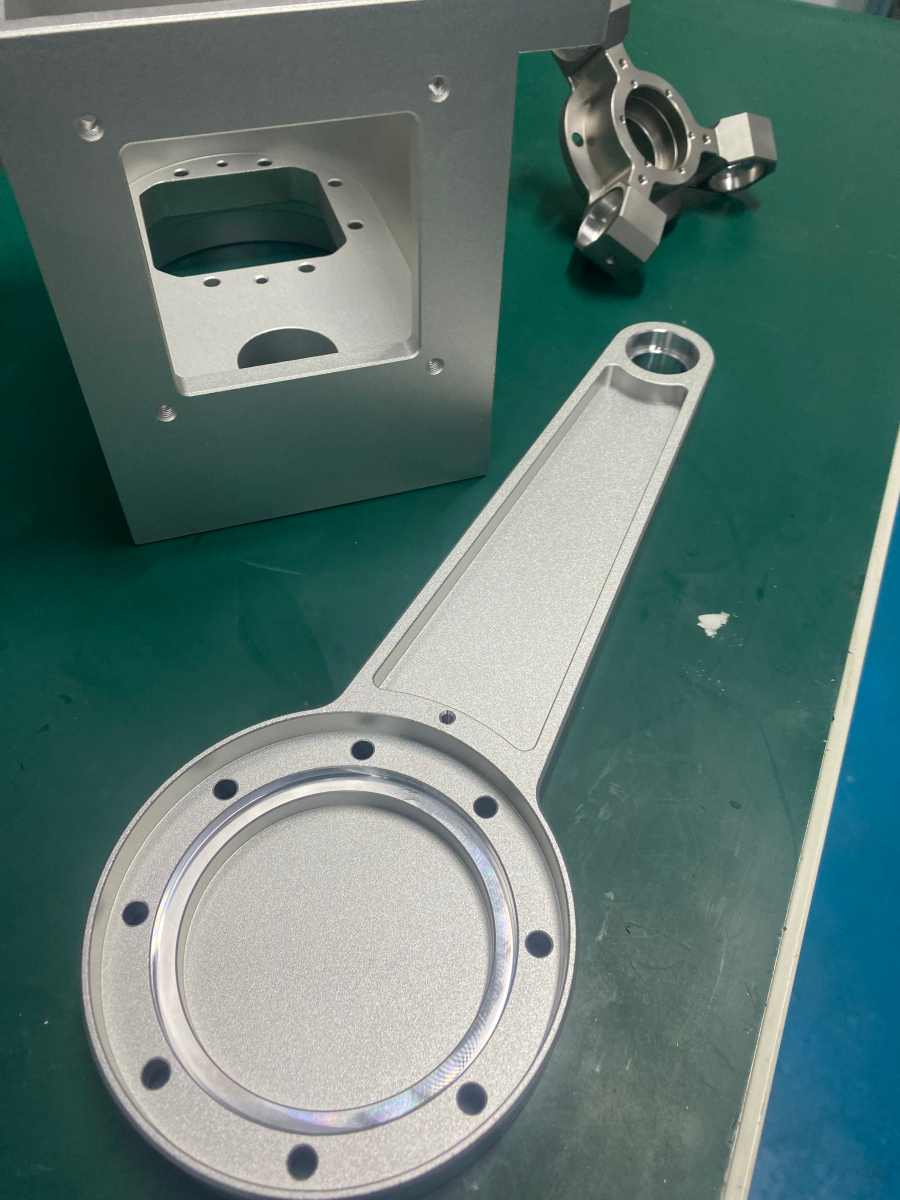

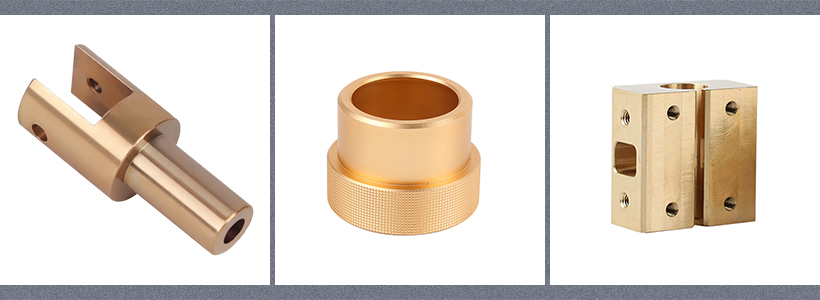

The equipment portfolio is the literal toolset for reliability. A partner with a balanced mix of advanced and specialized machines demonstrates both capability and stability.

Multi-Axis Machining Centers: The presence of modern 5-axis CNC machining capabilities is a strong indicator. It allows for complex parts to be completed in fewer setups, inherently reducing cumulative error and improving consistency compared to multiple 3-axis operations.

Comprehensive Supporting Equipment: Look for a full ecosystem: high-speed milling, precision turning (CNC lathes, Swiss-type), EDM (for intricate cavities or hardened materials), and grinding. This in-house breadth prevents reliance on external sub-suppliers for secondary operations, maintaining control over quality and timing.

Metrology and Inspection: Reliability must be measured. A partner should possess advanced CMMs (Coordinate Measuring Machines), optical comparators, surface roughness testers, and height gauges. The ability to provide comprehensive inspection reports with real data is proof of conformance.

H4: 2. The System: Certifications as a Framework, Not a Trophy

Certifications are the codified blueprint of a reliable system. They should represent an active, ingrained culture, not just framed certificates on the wall.

ISO 9001:2015: The universal foundation for a QMS, ensuring systematic control over processes, documentation, and corrective actions.

IATF 16949: For automotive clients, this is essential. It builds upon ISO 9001 with stringent requirements for continuous improvement, defect prevention, and supply chain management specific to automotive production.

ISO 13485: The critical standard for medical device manufacturing, emphasizing risk management, traceability, and validation of processes for regulatory compliance.

ISO 27001: An increasingly important trust marker, demonstrating commitment to information security—vital when sharing sensitive IP and design files.

A partner like GreatLight CNC Machining Factory exemplifies this systems-based approach. By structuring its operations around these international standards, it transforms subjective promises of quality into an objective, auditable reality. This framework ensures that every action, from programming to packaging, follows a controlled, repeatable, and improvable process—the very essence of reliability.

H4: 3. The Human Element: Engineering Collaboration and Service

Machines and systems are inert without skilled people. Reliability is ultimately delivered by a team.

DFM (Design for Manufacturability) Expertise: A reliable partner acts as an extension of your engineering team. They proactively review designs to suggest modifications that enhance producibility, reduce cost, and improve strength—without compromising function. This upfront collaboration prevents downstream problems.

Project Management Dedication: A single point of contact who understands both technical details and project logistics ensures clear communication and accountability.

Post-Processing and Finishing Integration: A true one-stop service that manages everything from machining to anodizing, plating, painting, or assembly under one roof eliminates coordination headaches and ensures finish quality aligns with the precision of the machined part.

H3: Case in Point: How Reliability Manifests in Real Projects

Consider a scenario from a high-performance automotive engine developer. They require a batch of complex aluminum intake manifolds with internal channels and tight sealing surface tolerances.

An Unreliable Service: Might quote aggressively based on the 3D model but fail to conduct a thorough DFM analysis. During production, tool deflection on thin walls leads to tolerance drift. Parts are delivered late, and a sample fails leak testing. The client now faces a crisis: rework delays the engine dyno testing, jeopardizing the entire development schedule.

A Reliable Service (e.g., GreatLight CNC Machining Factory): Would initiate the project with a DFM report, suggesting slight draft angles or radius adjustments to ensure stability in 5-axis machining. Using their advanced multi-axis centers, they machine the part in a single, rigid setup. Each part undergoes CMM verification against the CAD model, with a full inspection report delivered with the shipment. The parts arrive on schedule, fit perfectly, and perform flawlessly in testing. The client’s development cycle proceeds without a hitch.

H2: Making the Informed Choice: Your Checklist for a Reliable Partner

When evaluating potential suppliers for your next project, move beyond the quote sheet. Use this checklist:

Audit the Tech Stack: Do they have the appropriate multi-axis and supporting equipment for your part’s complexity? Can they show you similar case studies?

Demand Proof of System: Ask for their certification certificates and how their QMS is implemented in daily operations. Do they have in-house inspection reports you can review?

Test the Collaboration: Engage them in a DFM conversation on a sample part. Are their suggestions insightful and practical? Is communication responsive and technical?

Evaluate Transparency: Will they provide full material certifications and dimensional inspection data? What is their protocol for communicating production status or issues?

Assess the Full Scope: Can they handle the entire process chain you need, or will you be managing multiple vendors?

In conclusion, a reliable CNC machining service is the bedrock upon which innovative, high-quality products are built. It is a partnership defined by predictable excellence, rooted in advanced technology, enforced by rigorous systems, and delivered through collaborative expertise. In a landscape where margin for error is vanishingly small, choosing a partner who has institutionalized reliability—like those who build their practice on integrated advanced machining and international quality standards—is not just a good decision; it’s a critical competitive advantage. For those seeking to transform precision designs into flawless reality, the journey begins with selecting a foundation of unwavering reliability. To explore how industry leaders operationalize these principles, you can follow the ongoing developments at leaders in the field on platforms like LinkedIn.