Precision Ductile Cast Iron CNC Machined Parts Services – Turning Your Designs into Reality

GreatLight is a professional & experienced precision Ductile Cast Iron CNC Machined Parts in China, providing comprehensive solutions for all your custom part needs. We specialize in precision 5-axis CNC machining & lathe services, achieving tolerances of up to 0.001mm. As one of the best rapid prototyping companies in China, and an ISO 9001:2015 certified manufacturer, GreatLight is your trusted partner for high-quality metal and plastic components. We transform your 3D designs into tangible parts – quickly and efficiently.

Why Choose GreatLight for Your CNC Machining Needs?

- Precision & Accuracy: We consistently deliver Ductile Cast Iron CNC Machined Parts meeting stringent tolerances, ensuring functionality and performance.

- 5-Axis Capabilities: Complex geometries and intricate designs are no problem with our advanced 5-axis machining centers.

- Material Versatility: We work with a wide range of materials to meet diverse application requirements.

- Rapid Prototyping: From concept to prototype in days – accelerate your product development cycle.

- Competitive Pricing: Benefit from cost-effective manufacturing solutions without compromising on quality.

- Dedicated Support: Our experienced engineering team provides expert guidance throughout the entire process.

- ISO 9001:2015 Certified: Guaranteeing consistent quality and adherence to international standards.

Key Features of Our Ductile Cast Iron CNC Machined Parts:

- CNC Milling: Precision milling of complex Ductile Cast Iron CNC Machined Parts with tight tolerances.

- CNC Turning: High-speed, accurate turning for cylindrical components.

- 5-Axis Machining: For intricate designs and multi-sided machining.

- Material Expertise: Proficient in machining a broad spectrum of materials.

- Small to Large Production Runs: We cater to both prototyping and volume production.

- Surface Finishing Options: Including anodizing, polishing, plating, and more.

Suitable Applications:

Our CNC machining services are ideal for a wide range of industries and applications, including:

- Aerospace: High-precision components for aircraft and spacecraft.

- Automotive: Custom Ductile Cast Iron CNC Machined Parts for performance vehicles and prototypes.

- Medical: Surgical instruments, implants, and medical device components.

- Electronics: Enclosures, housings, and precision connectors.

- Industrial Equipment: Custom Ductile Cast Iron CNC Machined Parts and components.

- Robotics: Precision Ductile Cast Iron CNC Machined Parts for robotic systems and automation.

- Consumer Products: High-quality components for various consumer goods.

Material Capabilities:

| Material | Common Applications | Key Properties |

|---|---|---|

| Aluminum (6061, 7075) | Aerospace, Automotive, Electronics | Lightweight, High Strength, Corrosion Resistance |

| Stainless Steel (304, 316) | Medical, Food Processing, Marine | Corrosion Resistance, Durability, Hygiene |

| Brass (C36000) | Plumbing, Electrical Components, Decorative Items | Machinability, Conductivity, Aesthetics |

| Copper (C10100) | Electrical, Heat Sinks, Plumbing | High Conductivity, Corrosion Resistance |

| Titanium (Grade 5) | Aerospace, Medical, High-Performance Applications | High Strength-to-Weight Ratio, Corrosion Resistance |

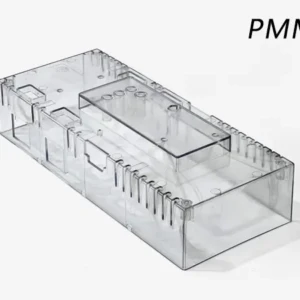

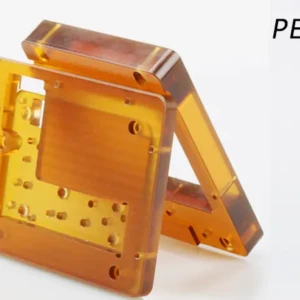

| Plastics (ABS, PC, POM) | Prototypes, Housings, Ductile Cast Iron CNC Machined Parts | Lightweight, Versatility, Cost-Effectiveness |

Machining Instructions – Ensuring a Smooth Process:

To ensure a successful outcome, please provide us with the following:

- CAD Model: A 3D model of your part in a standard format (STEP, IGES, STL, etc.).

- 2D Drawings: Detailed 2D drawings with all critical dimensions and tolerances.

- Material Specification: Clearly specify the desired material.

- Quantity: Indicate the number of Ductile Cast Iron CNC Machined Parts required.

- Surface Finish: Specify any desired surface treatments (e.g., anodizing, polishing).

- Special Requirements: Any unique requirements or considerations for your project.

Customization Guide – Bringing Your Vision to Life:

GreatLight excels at custom CNC machining. We work closely with you throughout the entire process:

- Design Review: Our engineers will review your designs for manufacturability and offer suggestions for optimization.

- Material Selection: We assist in selecting the most appropriate material for your application.

- Prototyping: We can quickly create prototypes to validate your design and functionality.

- Production Planning: We develop a detailed production plan to ensure efficient and timely delivery.

- Quality Control: Rigorous quality control procedures are implemented at every stage of the process.

Ready to Get Started?

Contact GreatLight today for a free quote and let us help you turn your designs into reality. We are committed to providing exceptional quality, competitive pricing, and outstanding customer service.

Great Light – Leader in Ductile Cast Iron CNC Machined Parts

Reviews

There are no reviews yet.