Precision CNC Machining Manufacturing Services – 5-Axis Lathe Capabilities

Unlock Complex Geometries & Superior Precision with GreatLight

GreatLight is a professional & experienced precision CNC machining factory in China, providing high-quality, custom-engineered solutions for a wide range of industries. We specialize in precision 5-axis CNC machining & lathe services with a remarkable tolerance of 0.001mm, delivering intricate parts with exceptional accuracy and efficiency. As one of the best rapid prototyping companies from China, and an ISO 9001:2015 certified manufacturer, GreatLight – Leader in CNC Machining – is your trusted partner for turning designs into reality.

Why Choose GreatLight for Your CNC Machining Needs?

We understand that your projects demand precision, quality, and speed. That’s why we’ve invested in state-of-the-art 5-axis CNC lathe technology and assembled a team of highly skilled engineers and machinists. Our commitment to excellence ensures:

- Complex Geometry Capability: 5-axis machining allows us to create incredibly complex parts with undercuts, angled holes, and intricate features that are impossible to achieve with traditional machining methods.

- Superior Surface Finish: Our advanced equipment and skilled operators deliver parts with exceptional surface finish, reducing the need for secondary operations.

- Tight Tolerances: We consistently achieve tolerances down to 0.001mm, ensuring your parts meet the most demanding specifications.

- Rapid Prototyping & Production: From single prototypes to large production runs, we offer flexible solutions to meet your timeline and budget.

- Material Versatility: We expertly machine a broad spectrum of materials, offering you design freedom and optimal performance.

- Dedicated Project Management: A dedicated project manager will guide your project from quote to delivery, ensuring clear communication and on-time completion.

Suitable Applications & Industries

Our CNC machining services are ideal for a diverse range of applications across various industries, including:

- Aerospace: Precision components for aircraft engines, landing gear, and structural elements.

- Medical: Surgical instruments, implants, and diagnostic equipment.

- Automotive: Engine components, transmission parts, and custom tooling.

- Electronics: Connectors, housings, and heat sinks.

- Robotics: Custom gears, housings, and robotic arms.

- Industrial Automation: Precision parts for automated machinery and equipment.

- Oil & Gas: Components for downhole tools and pipeline systems.

Material Capabilities

We expertly machine a wide variety of materials to meet your specific requirements:

| Material Type | Examples | Common Applications |

|---|---|---|

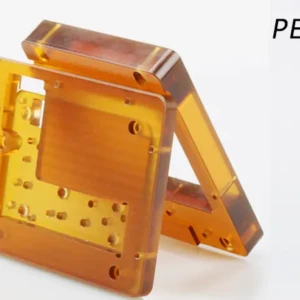

| Plastics | ABS, PC, POM, Nylon, PTFE, Acrylic | Prototypes, housings, gears, insulators |

| Metals | Aluminum (6061, 7075), Stainless Steel (304, 316), Steel (4140, 1045), Titanium | Structural components, housings, shafts, fasteners |

| Alloys | Brass, Bronze, Copper | Electrical components, bearings, decorative parts |

Machining Instructions – Ensuring Optimal Results

To ensure a smooth and efficient machining process, please provide the following:

- CAD Models: We accept a variety of file formats including STEP, IGES, STL, DWG, and DXF. Solid models are preferred.

- Technical Drawings: Detailed 2D drawings with clear dimensions, tolerances, and material specifications.

- Material Specification: Specify the exact grade and type of material required.

- Surface Finish Requirements: Indicate the desired surface roughness (Ra value).

- Quantity: Specify the number of parts needed.

- Special Instructions: Any specific requirements regarding heat treatment, plating, or other processes.

Customization Guide – Your Design, Our Expertise

At GreatLight, we excel at bringing your unique designs to life. Here’s how we tailor our services to your specific needs:

- Quote Request: Submit your CAD model and specifications through our website or via email. We provide a detailed, competitive quote within 24-48 hours.

- Design for Manufacturability (DFM) Review: Our experienced engineers will review your design and offer suggestions for optimization, cost reduction, and manufacturability.

- Programming & Setup: We use advanced CAM software to program our 5-axis CNC lathes, ensuring precision and efficiency.

- Machining & Quality Control: Our skilled machinists carefully operate the machines, and our quality control team rigorously inspects each part to ensure it meets your specifications.

- Delivery: We offer secure and reliable shipping options to deliver your parts on time and within budget.

Ready to Discuss Your Project?

Contact GreatLight today to experience the difference that precision, expertise, and dedication can make. We are committed to providing you with the highest quality CNC machining services and exceeding your expectations.

Automotive Prototyping Solutions –

Dry machining titanium saved 300L coolant/month – eco-warriors!