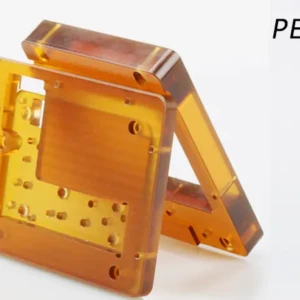

Precision CNC-Machined PP Polypropylene Plastic Parts

Superior Performance & Versatility

Crafted from premium Polypropylene (PP) polymer, our CNC-machined components deliver exceptional chemical resistance, fatigue strength, and thermal stability. Ideal for applications requiring lightweight yet durable solutions that withstand acids, solvents, and repetitive stress.

Key Features

- Medical & Food Safe: FDA-compliant PP material ensures non-toxicity for sterile environments and food-contact applications

- Corrosion Resistance: Unmatched resilience against aggressive chemicals, acids, and alkalis

- Low-Friction Design: Smooth surfaces reduce wear in dynamic assemblies

- Electrical Insulation: Excellent dielectric properties for electronic housings and connectors

- Moisture Barrier: Near-zero water absorption maintains dimensional stability

Precision Engineering Capabilities

Utilizing advanced 5-axis CNC technology, we achieve micron-level tolerances (±0.01mm) for complex geometries:

- Custom bushings, gaskets, valves, and fluid handling components

- Thin-walled enclosures and intricate prototypes

- High-volume production with batch consistency

Industry Applications

Optimized for demanding sectors:

🔬 Medical Devices: Sterilizable lab equipment, surgical tool components

🥫 Food Processing: Conveyor parts, packaging machinery fittings

🔋 Electronics: Insulating mounts, battery casings

🚗 Automotive: Lightweight engine bay components, fluid reservoirs

⚙️ Industrial: Chemical pump parts, corrosion-resistant fixtures

📦 Quality Assurance:

Every part undergoes rigorous inspection for dimensional accuracy, surface integrity, and material certification. Compliant with ISO 9001 standards.

✅ Custom Solutions:

Submit your CAD files for instant DFM feedback and volume pricing. Prototypes available in 3 days, full production in 2 weeks.

Engineer smarter systems with precision-machined PP components – where chemical resilience meets exacting mechanical performance.

Automotive Prototyping Solutions –

500k automotive connectors: CpK consistently >1.67 for 24 months.