basic knowledge

The 3D body scanner measures your body in 360 degrees. (Source: MakeShape/YouTube)

3D body scanners are changing the way we approach every aspect of our lives. Shopping for clothes, securing airports, and planning healthcare are all made easier and more convenient with 3D body scanners. All this is achieved using 3D technology which provides users with an accurate and comprehensive view of the human body.

These scanners capture the shape of the human body through a series of data points that are grouped into3D model. It combines 3D photographic technologies such as structured light scanners, depth sensors and stereo vision, meaning it uses various measurement methods to cover the different shapes and complexities of the human body and combines them into a map multi-data. These data points are connected according to ratios extracted from the scan measurements, and through these connections, a complete 3D scan is achieved. It is used in various applications benefiting from hyper-personalization, such as manufacturing shoes, providing nutritional advice or installing medical devices.

Although currently3D body scanning technology is still dominated by industry professionals, but it is a fascinating process that allows everyone to fully understand what 3D technology can produce. And it’s becoming more and more common.

to use

3D printed selfies are a fun way to use a 3D body scanner! (Source: Dezeen)

Break it down,3D body scanning can be reduced to collecting body data points. This data forms the basis for countless uses and discussion points, all of which can be made from the same starting point. Here are some of the most popular and effective uses of 3D body scanning that we have found so far:

custom clothing design: What if you could order tailor-made clothes without ever having to go to a store or tailor? This uses3D body scanning is used for clothing design purposes by businesses and individuals. Relying on predefined measurements often causes more confusion than help, and in-person modifications require that you have the time and transportation to travel and stay through the lengthy adjustment process. 3D body scanners allow you to get your exact measurements in minutes, saving you time and energy when trying to find the perfect clothes for your wardrobe.

Reference:The large amounts of data used in 3D body scans raise privacy concerns while providing valuable real-world information. When users agree to have their data points added to the average body’s basic statistics, they contribute to science and help reveal something we still don’t understand about ourselves and the way we work.

Morphometric assessment: Morphometrics is a more precise version of benchmarking, which studies the relative size between objects and the area of geographic space. Internal medicine uses it primarily for organ localization and evaluation, which isThis is where the 3D body scanner comes into play. Although a 3D body scanner is not compatible with X-rays, it is capable of providing millions of data points on the shape of the outer surface of the skull (or stomach or feet). Studying the specifics of an individual’s external surface can help in drawing. pay attention to abnormal areas and their value. Areas of concern requiring further research.

Medical and fitness monitoring: People lie about their self-rated health. The wrist activity tracker has a defect and the odometer is difficult to calibrate– but 3D body scans can reveal the truth. A brief analysis can produce a holistic picture of data on posture, height, weight, body shape, muscle mass and much more. They are a great way to establish a baseline and track changes in any area. This is why gyms are now investing in the 3D body scanning aspect of their fitness programs. There are also many medical ways to use this data, from tracking pregnancy growth to customizing the fit of prosthetics, all with one machine.

super realistic3D printing (3D printing selfie!): If you want to commemorate your awesome cosplay costume, getD&D symbols come to life, or if you just want to commemorate your loved ones and friends with something more solid than a photo, take a 3D selfie! After taking a photo of yourself using a 3D body scan, transfer your data to any 3D printer to bring your miniatures to life.

Scanner type

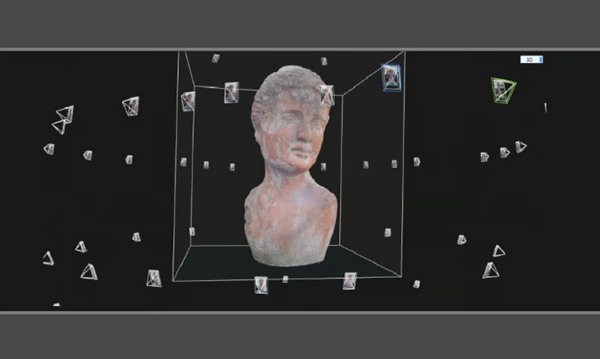

Photogrammetry uses thousands of photos taken from different angles to map3D model. (Source: Sculptéo)

Each useIndustries that use 3D body scanners have refined their designs to meet their specific needs. But behind all the details, 3D body scanners work in one of the following ways:

Photogrammetry:The 3D body scanner takes multiple photos from different angles simultaneously. The scanner then uses algorithms to combine the photos into a 3D image. This method is fast, colorful and textured, and instantly captures all data points.

Structured light: During this process,A 3D body scanner emits rays of light that are projected onto an object and triangulated against each other to form a scan. It is very detailed and precise, but requires the subject to remain still for longer periods of time than photogrammetry.

mix:A few3D body scanners use a combination of photogrammetry and structured light to obtain the maximum amount of scanned information. For example, 3D selfie kiosks tend to use a hybrid approach in order to print the end result as detailed as possible.

challenge

to useTailoring with a 3D body scanner cannot accommodate subjective preferences, like whether you like a slim fit or a loose fit. (Source: Poliklinika Bagatin)

to use3D body scanners are pretty simple on the surface: you stand there and the scanner takes a few minutes at most to do its job, then waits a little longer for the software to compile your scan.

However, if you don’t know what you want to do, use3D body scanners can be tricky. The devil is in the details, and if you don’t understand them correctly, you might wonder what went wrong. Check out these tips to get the most out of your process so your final product gives you the precision and support you need:

Difficulty scanning small, hidden areas:3D body scanners are surface-based. This means they are good at capturing what they see, but not as good at areas hidden or obscured by natural human posture, like the armpits. If you need to capture areas that are not naturally exposed, take this into account during your scan pose. For example, extending your arms or lifting your long hair to show where your neck meets your head can greatly improve the visibility of the scan.

Unable to incorporate subjective preferences:The data collected by a 3D body scanner is a fact about how things happen, and sometimes you prefer to research what’s possible based on the information you already have. This is especially true with items like clothing, where people have personal preferences for how close an item fits their exact measurements. A 3D body scanner alone cannot tell whether someone prefers a slim or loose fit, a long or short hem, or a more or less seam structure. Therefore, personal communication always plays a vital role when using 3D body scanning technology.

Risk of oversimplification:regardlessNo matter how many data points a 3D body scanner extracts from your measurements, it still needs those little jumps between the points to connect them into a whole. This oversimplification risks missing important nuances, especially when there are large areas between groups of data points. When not enough points are connected, the outline becomes blurred, resulting in data loss. Fortunately, 3D body scanners are getting more accurate with each iteration. If you need the best accuracy, look for a 3D body scanner that uses structured light.

Large amounts of data require powerful processing capabilities: This is another area of treatment that is constantly improving. But the reality is that3D body scanners always produce a large number of data points. Their ability to turn these data points into useful data depends on your processing machine, so if you’re not willing to sacrifice any detail from your 3D body scan, make sure you have a computer capable of saving this data .

Material cost:most3D body scanners all cost more than five figures, limiting their use as personal machines. You can solve this problem by using 3D body scanners installed in public spaces, such as the 3D selfie kiosks that are starting to appear in tourist areas and shopping malls around the world. If that’s not yet practical for you, Naked Labs has launched a home 3D body scanner for under $1,000.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.