2023Year5moon18On the same day, Mohou.com learned that from the Korea Institute of Science and Technology(CHEST)MIT researchers recently demonstrated a conductive elastomeric ink capable of printing free-standing structures in any orientation. This new ink uses an emulsion system to achieve the required printing flow properties, and its release could lead to many innovations in the field of expandable and wearable electronics. This study entitled “Omnidirectional printing of elastic conductors for three-dimensional stretchable electronics“The article was published in”Natural electronics“Newspaper, byByeongmoon Lee, Hyunjoo Cho, Sooyeon MoonCo-written by others.

Links to related articles:

3D Printed electronics is a growing market, but because manufacturers treat it like a trade secret, its true level of development is difficult to understand.3D Printing conductive elastomers has always been an area of great interest. Currently, printing of conductive elastomers is limited to two-dimensional surfaces because most inks are limited by their rheological properties and cannot support their weight immediately after printing. However, if a material could print free-standing structures while being flexible enough to move with the body, it could maximize the fidelity of wearable devices and create devices tailored to each patient’s complex circuitry.CHESTThe research team took this research idea and found a way to manipulate the rheological properties of the ink to print elastic conductors in all directions.

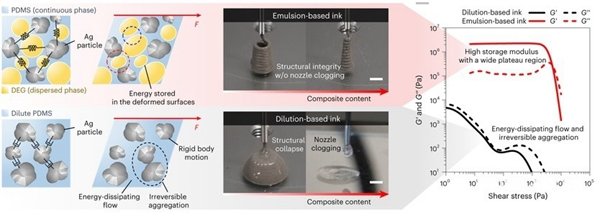

CHESTThe emulsion system used by the researchers consists of conductive elastomeric composites (silver,Agmulti-walled carbon nanotubes,MWCNTand polydimethylsiloxane,PDMS), immiscible solvent (diethylene glycol,DEG) and emulsifying solvent (chloroform,CHCl3). It turns out thatDEG is a key factor in achieving proper rheological properties, as it prevents fillers from settling into the dispersion and imparts pseudoplastic and lubricating properties, thereby preventing nozzle clogging, resulting in stable printing.

△Displays diluted conductive elastic ink and CHEST Illustration of the differences between emulsion-based conductive elastomeric inks. (source:NatureElectronics)

The minimum characteristic size of fillers in emulsion inks is less than 100 mmMaximum feature size is a few millimeters. The ink also achieves impressive results up to150%extensibility and improved electrical conductivity due to the local surface microstructure formed when the dispersing solvent evaporates.

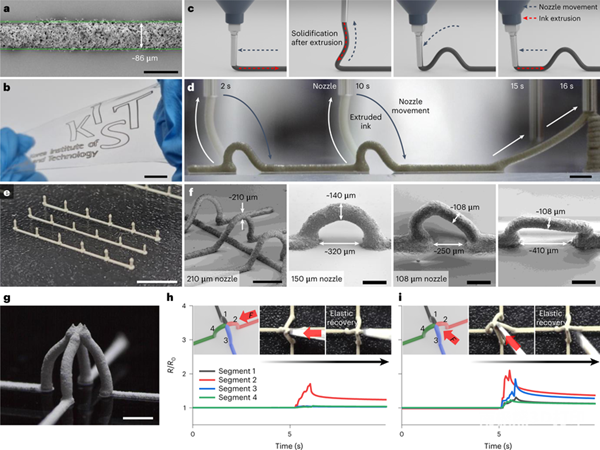

△The picture shows CHEST Printability, extensibility and characteristic dimensions of inks. (source:NatureElectronics)

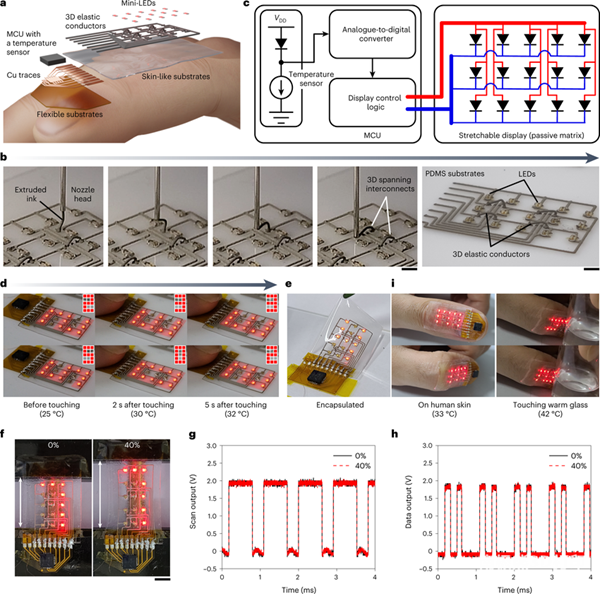

CHESTThe new method will allow printing various3Dwiring diagram, they demonstrate its capabilities in the image below. Researchers use their new emulsion conductive ink as wiring, miniDIRECTEDand a microcontroller unit with a temperature sensor, creating a temperature sensor that can be mounted on the skin. The sensor’s expandable dot-matrix display easily reads the ambient air temperature and when researchers first touch the device, they can see the temperature change of25℃ changes to32℃, when exposed to hot glass, the temperature rises from 33℃ changes to 42℃。

△The figure shows the KIST 3D Temperature sensor with printed wiring. (source:Natural electronics)

Conductive ink still needs improvement before it can be commercialized, but it still opens the door to new possibilities in wearable and stretchable electronics. The author even claims that the ink formula can be easily modified to meet the desired properties required in different situations. Time will tell how this technology will be implemented, but if it can help electronic devices interact more easily and effectively with the human body, it appears the field is moving in the right direction.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.