3DDentistry is a field in which printing is becoming increasingly popular. dental field3DPrinting is a manufacturing tool that allows you to create the desired product based on the needs and morphology of each patient. Whether through the use of resin additive manufacturing or powder bed fusion additive manufacturing, new doors are opening for professionals in dental practices and laboratories. In addition, dental care3DPrinting often goes hand in hand with other digital solutions, such as newGUJATtools or dental3DScanner. In short, this new technology brings many advantages to dentistry. Today I would like to introduce you3DThe main applications of printing in dentistry.

● Dental field3Dscanning

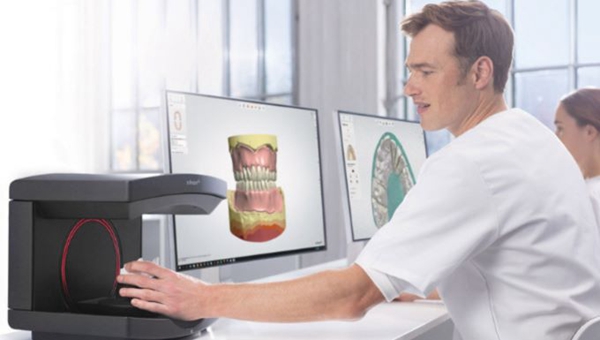

Although it is not dentistry per se3DPrinting applications, but we cannot fail to mention3Dscanning. exist3DPrinting in dentistry,3DThe use of scanners is becoming more and more common. This is the first step in the digital workflow, with the help of3D Scanners, healthcare professionals are able to scan the inside of a patient’s mouth using an intraoral scanner or scan impressions via a laboratory scanner. A digital file of the impression is created and can be STL Export format for3DPrint. to use3DOne of the advantages of dental scanners is their high accuracy. It also offers the possibility of producing personalized devices according to the patient’s dental morphology. For example, if a patient needs an emergency prosthesis, there is no need to leave new model data because these models have already been scanned in previous treatments, which can save a lot of time for patients and medical staff.

△Dental 3D Source of scanner images:3Shape

●Dental crowns and bridges

Crowns and bridges are the most common products in dental treatment methods because they can be used to replace missing teeth. The key difference between the two is that a dental crown is used to cover a damaged or decayed tooth and can be placed over the damaged area. They can also cover dental implants in the absence of teeth. A dental bridge is used to replace missing teeth and consists of two crowns (one on each end) and a few denture bridges.3DPrinting is playing an increasingly important role in dentistry and resins can be used3DPrint to create ephemeral, high-precision, beautiful images3DPrint crowns and bridges. This technology is becoming increasingly popular because it is more cost-effective and faster than traditional milling processes.

△Wrought Image source:form laboratories

●Aligners and retainers

Additive manufacturing is producing more and more dental devices, not only increasing the speed of manufacturing, but also enabling customization, which is a very important aspect in this field because everyone’s teeth are different. Retainers, or orthodontic appliances, are devices used to move a patient’s teeth. The medical staff first scans the patient’s mouth, then uses GUJAT software, obtain the required files and export them to the3DPrint on the printer. The most commonly used technology is resin3DPrint, likeYEARS、DLPOrMSLA. Depending on user needs, some parameters can be changed, such as printing time, printing area, etc.

△Image source:form laboratories

●Implants

Every time we lose a tooth, it must be treated quickly with an implant, otherwise the missing area around the tooth will deteriorate due to lack of pressure. Thanks to additive manufacturing, implants in the dental field can not only be produced on demand and therefore more quickly, but also be personalized. This is especially important in dental care because everyone’s mouth and smile are unique. With the help of dental implant surgery3DPrinted with precision manufacturing methods, there are no limitations on the patient’s bite ability or chewing function. Also,3DPrinting is also considered a more economical method, with continued improvements through innovation making it easier to produce dental implants.

△Image source:form laboratories

●Surgical guide

3D One use in which printing is particularly valuable in dentistry is in surgical guides for dental implants. This is one of the latest advancements that has revolutionized surgical procedures, even outside of dentistry. During surgery, it is sometimes difficult for the dentist to place the implant in the right place due to awkward angles and inability to see clearly. As a result, many implants are poorly placed, which can lead to many oral complications. Surgical guides are used to resolve these problems. More specifically, the guide helps the dentist to correctly place the dental implant in the right place. It is a disposable device that is placed directly on the patient’s teeth and has a hole that allows the implant to be placed in the right place, at the right angle and at the right depth. This method provides greater accuracy, approximately three times greater than manual placement.

△Photo source: Dentiste Arenas

●Replicas and anatomical models

In dentistry, an anatomical model is the jaw or mouth. model for use in patients–Clinicians and clinicians–Planning and discussion of surgical interventions between clinicians. They provide detailed images of the required area and reduce the risk of procedural errors because the dentist must work with physical anatomy.3D What exactly is printing for? Traditionally, making plaster models of crowns and dentures was a slow, manual process that required waiting for the models to be ready.3DPrinting can be used to generate a model based on intraoral scans quickly and efficiently as it is built layer by layer by the printer. For the basic model you can useFDMwith silk, but for more complex reproductions it is possible to useYEARSProduce resin models.

△Oral Anatomy Model Image Source:freepik.com

● dental prostheses

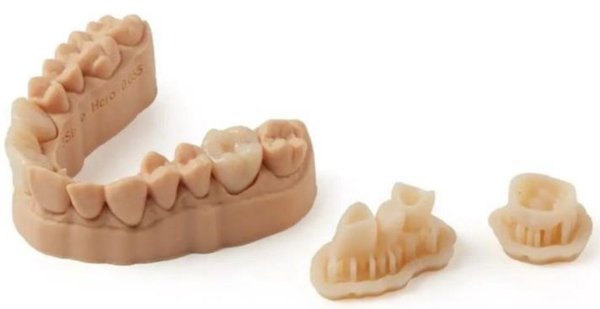

to use 3D Printing to produce dentures is an emerging technology that has the benefit of simplifying the process. The traditional method of making dentures involves milling them through a resin base, which is complex, time-consuming and requires multiple visits to the dentist.3D Printing allows for faster and less expensive production of prosthetics. Although the method is not yet perfect, limited by aesthetics and low resolution printers, many developments have taken place. Recently, new materials for the production of dentures have gained ground THISlogo (i.e. inEEAMarked as safe), and patient studies have shown that dentures are acceptable to users.form laboratoriesSome companies already offer custom denture solutions, with their websites suggesting savings of more than half compared to fully milled teeth.

△3DA printed prosthetic set (left) and a milled set (right). Image source:Aegis dental network

●Casting model

3D The impression can also be used for indirect dental procedures. in general3DPrinting can be used to create final dental parts, including crowns and bridges, copings and substructures, but it also plays a role in creating models. Cast dental models are precise three-dimensional replicas of a patient’s teeth and are used not only to study the mouth, but also to create crowns, fixed bridges and dentures. Anyone who has had orthodontic work or visited a dentist has had the experience of biting down on uncomfortable wax to create this mold. pass 3D Scan and print, the process is simplified to create high precision molds by printing, cleaning, removing supports, sintering, etc. to obtain the final product.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.