introduce

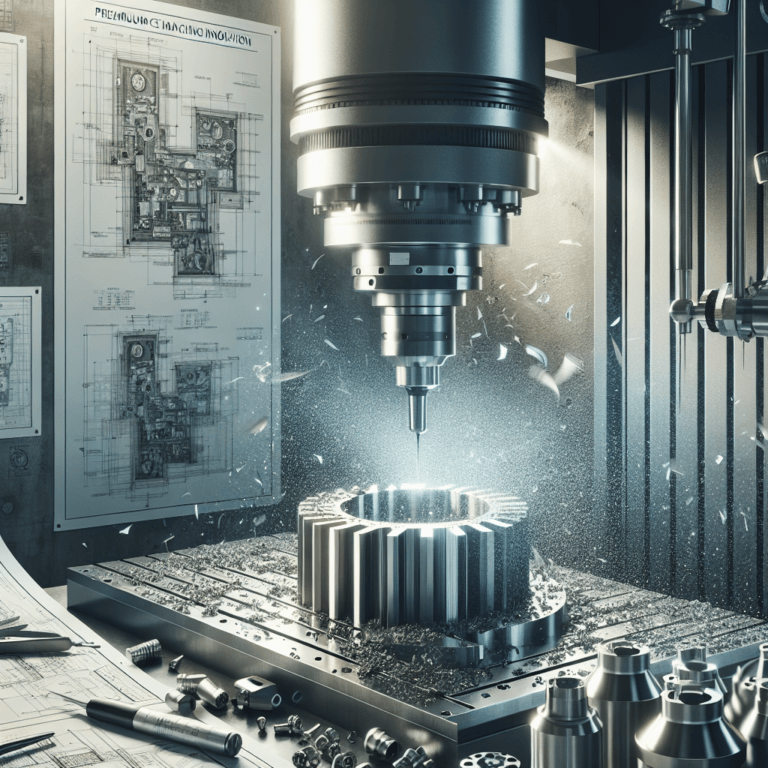

In the rapidly evolving manufacturing sector, CNC (computer numerical control) machining is a key innovation that is reshaping the landscape of production quality, efficiency and speed. The fusion of advanced technology and traditional machining techniques has ushered in a new era defined by precision engineering and complex design capabilities. This article explores the latest innovations in CNC machining that improve precision, quality and operational efficiency, providing comprehensive insights for industry professionals and enthusiasts.

Learn about CNC machining

CNC machining is a manufacturing process that uses computer-controlled tools to precisely cut materials into desired shapes and sizes. This technology is indispensable in various industries including aerospace, automotive, medical devices and electronics. The shift from manual machining to CNC machining has made the production process faster and more precise.

Key components of CNC machining

computer control: The heart of CNC machining lies in its computer system, which interprets the design into a language that the machine can understand. G-code is the standard programming language for CNC and specifies the movement, speed and coordination of the tool.

CNC machine tools: Various types of CNC machine tools such as CNC mills, lathes, plasma cutters, and milling machines have different functions. Each machine type is optimized for specific applications, enhancing manufacturing versatility.

- Material selection: The performance of CNC machining depends largely on the choice of materials. Metals, plastics and composite materials each have unique properties that affect processing methods and results.

The evolution of CNC machining

Over the decades, CNC machining has evolved from basic operations to complex multi-axis systems capable of executing complex designs with unparalleled accuracy. Software and hardware developments have played an important role in this evolution.

From 3-axis machining to 5-axis machining: Traditional 3-axis machines operate along three linear axes (X, Y, and Z), while modern 5-axis machines add two rotary axes for enhanced maneuverability. This shift allows more complex parts to be machined in a single setup, reducing time and potential errors.

- Additive Manufacturing Integration: The combination of CNC machining and additive manufacturing technologies such as 3D printing expands capabilities. This integration enables the production of complex parts that were previously impossible or economically unfeasible.

Innovation drives CNC machining accuracy and quality

1. Advanced software solutions

Modern CNC machining relies heavily on sophisticated software platforms to enhance design, simulation and machining processes.

CAD/CAM integration

Computer Aided Design (CAD): CAD software allows engineers to create accurate 3D models of parts, facilitating seamless communication between the design and manufacturing stages. Advanced CAD systems also include simulation tools to predict machining challenges before actual production begins.

- Computer Aided Manufacturing (CAM): CAM software converts CAD designs into machine instructions. Innovations in CAM software, such as adaptive machining and toolpath optimization, ensure that the cutting process is as efficient as possible, minimizing waste and reducing cycle times.

Cloud computing and artificial intelligence

Cloud-based solutions: The emergence of cloud technology makes real-time data collection and analysis possible. Engineers and operators can remotely access machining parameters, promoting collaborative problem-solving and decision-making.

- Artificial Intelligence (AI): AI-driven system enhances CNC machining processes by learning from past operations. Machine learning algorithms can predict tool wear, optimize cutting parameters and recommend maintenance schedules, reducing downtime and increasing productivity.

2. Enhance automation technology

Automation continues to be a game changer in CNC machining, improving accuracy, efficiency and repeatability.

Robot integration

Robots are increasingly integrated into CNC machining environments, performing tasks such as material handling, inspection and even secondary operations. This collaboration reduces manual intervention, ensures consistent quality, and frees up human resources to perform more complex problem-solving tasks.

Intelligent processing system

IoT connection: Internet of Things (IoT) technology connects CNC machines to the network to enable real-time monitoring of machine performance and operating conditions. Operators can remotely adjust settings, respond to alarms and optimize processes on the fly.

- Predictive maintenance: Advanced sensors detect abnormal machine performance and signal when maintenance is needed. This proactive approach prevents costly breakdowns and extends the overall service life of the machine.

3. Material science innovation

The choice of materials significantly affects the quality of CNC machining. Recent advances in materials science have broadened the horizons of CNC capabilities.

High performance alloy

Industries such as aerospace and automotive require lightweight yet strong materials. The development of advanced alloys such as titanium and carbon fiber composites has revolutionized the types of parts machinists can produce.

Coatings and treatments

Innovative coatings improve the durability and performance of machine tools and finished products. Coating technologies such as PVD (physical vapor deposition) enhance wear resistance, while surface treatments can modify properties such as friction and heat resistance, allowing for greater precision during machining.

4. Precision measurement and inspection

Quality assurance is crucial in CNC machining; new technologies aim to improve measurement accuracy and inspection processes.

In process measurement system

Integrating measuring systems directly into CNC machine tools enables real-time monitoring of machining results. Systems such as laser scanners and vision systems provide continuous feedback, allowing immediate adjustments to maintain tolerances.

Advanced detection technology

With innovations in 3D scanning and X-ray computed tomography (CT), manufacturers can gain greater insight into the integrity of machined parts. These technologies enable non-destructive testing of complex geometries, ensuring defects are discovered early in the production process.

5. Sustainability of CNC machining

As the industry shifts toward sustainability, CNC machining technology continues to evolve to accommodate environmentally friendly practices.

energy saving machine

Newer CNC machining centers are designed with energy efficiency in mind. Features such as regenerative drives and optimized spindle design reduce energy consumption without compromising performance.

waste reduction technology

Innovative strategies for minimizing material waste include nesting software that maximizes material utilization and recycling programs that reuse waste materials from machining processes.

The future of CNC machining innovation

Looking to the future, the prospects for CNC machining will continue to grow. The fusion of digital manufacturing with traditional practices will lead to greater levels of customization, efficiency and precision.

1. The role of digital twins

Digital twin technology can create virtual replicas of physical systems and will occupy an important position in the field of CNC machining. By simulating machining processes, manufacturers can predict potential bottlenecks, optimize workflows and enhance predictive maintenance strategies.

2. Sustainable Manufacturing Practices

As environmental concerns persist, CNC machining will adopt sustainable practices that prioritize resource conservation and minimize ecological footprints. Look forward to further innovations in materials science that will lead to the development of more environmentally friendly processing materials.

3. Collaborative design and production

Future CNC machining workflows will integrate collaboration platforms where design teams, engineers and machinists work side by side in real time. This holistic approach will promote innovation and responsiveness to market needs.

in conclusion

Once viewed simply as a mechanized process, CNC machining is now at the forefront of manufacturing innovation. The relentless pursuit of precision and quality continues to inspire advances in software, automation, materials science and sustainability. By adopting these innovations, manufacturers can not only increase production capabilities but also adapt to the changing dynamics of today’s industry.

For organizations hoping to remain competitive in an increasingly complex market, investing in cutting-edge technology is critical. The field of CNC machining will undoubtedly continue to undergo transformation, driven by the integration of new technologies and methods.

FAQ section

Q1: What is CNC machining?

CNC machining is a manufacturing process that uses computer-controlled machinery to create precision parts by cutting, shaping, or assembling materials based on digital design.

Q2: What are the benefits of CNC machining?

Benefits include increased accuracy, repeatability, the ability to handle complex designs, increased efficiency, reduced human error, and the ability to produce high volumes.

Q3: What is the difference between three-axis and five-axis CNC machining?

3-axis machines operate along three linear axes (X, Y, Z), while 5-axis machines introduce two additional rotary axes. This capability on 5-axis machines allows for more complex shapes and reduces the need for multiple setups.

Q4: How does automation improve CNC machining?

Automation enhances CNC machining by increasing production speeds, reducing human errors, optimizing workflows, and enabling continuous operations through technologies such as robotics and IoT integration.

Q5: What are the emerging trends in CNC machining?

Emerging trends include further integration of digital twin technology, the use of sustainable materials, advances in artificial intelligence and machine learning, and collaboration platforms that allow real-time interaction between design and manufacturing teams.

By focusing on these key areas of innovation, organizations can leverage the full potential of CNC machining to meet the needs of modern manufacturing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.