High-temperature alloys, also called heat-resistant alloys or heat-resistant alloys, can operate in high-temperature oxidizing atmospheres of 600-1000°C and gas corrosion conditions, and have good strength properties thermal stability and thermal fatigue. properties.

High temperature alloys are divided into nickel-based high-temperature alloys, iron-based high-temperature alloys and cobalt-based high-temperature matrix element alloys. They are widely used in various fields, including aviation, aerospace and energy. production equipment, shipbuilding and other industries.

1

Classification and characteristics of high temperature alloys

High temperature alloys can be roughly divided into three categories according to basic elements, forming processes and strengthening methods (the proportion of the application range of alloy materials in parentheses)

Divided according to the basic elements contained in the alloy: divided into iron-based superalloys (accounting for 14.3%), cobalt-based superalloys (accounting for 5.7%) and nickel-based superalloys (accounting for 80%) ;

Divided according to the dimension of alloy manufacturing process: divided into high temperature deformed alloys (accounting for 70%), high temperature cast alloys (accounting for 20%) and new high temperature alloys (powdered high temperature alloys);

Divided according to the dimensions of alloy strengthening methods: divided into solid solution strengthening type, precipitation strengthening type, oxide dispersion strengthening type and grain boundary strengthening type.

2

Classification and characteristics of high temperature alloys

01.

Main alloy elements

Name: iron-based high temperature alloy

Features: Low operating temperature (600-850℃). Typical grades include GH4033, GH4169, etc.

Application: Mainly used in low temperature engine parts, such as low temperature aerospace engines and industrial gas turbine disks, casings, shafts and other parts, as well as some load-bearing parts and fasteners.

Name: Nickel-based high temperature alloy

Features: Operating temperature is medium to high (650-1000℃). Typical grades include GH2036, GH2135, etc.

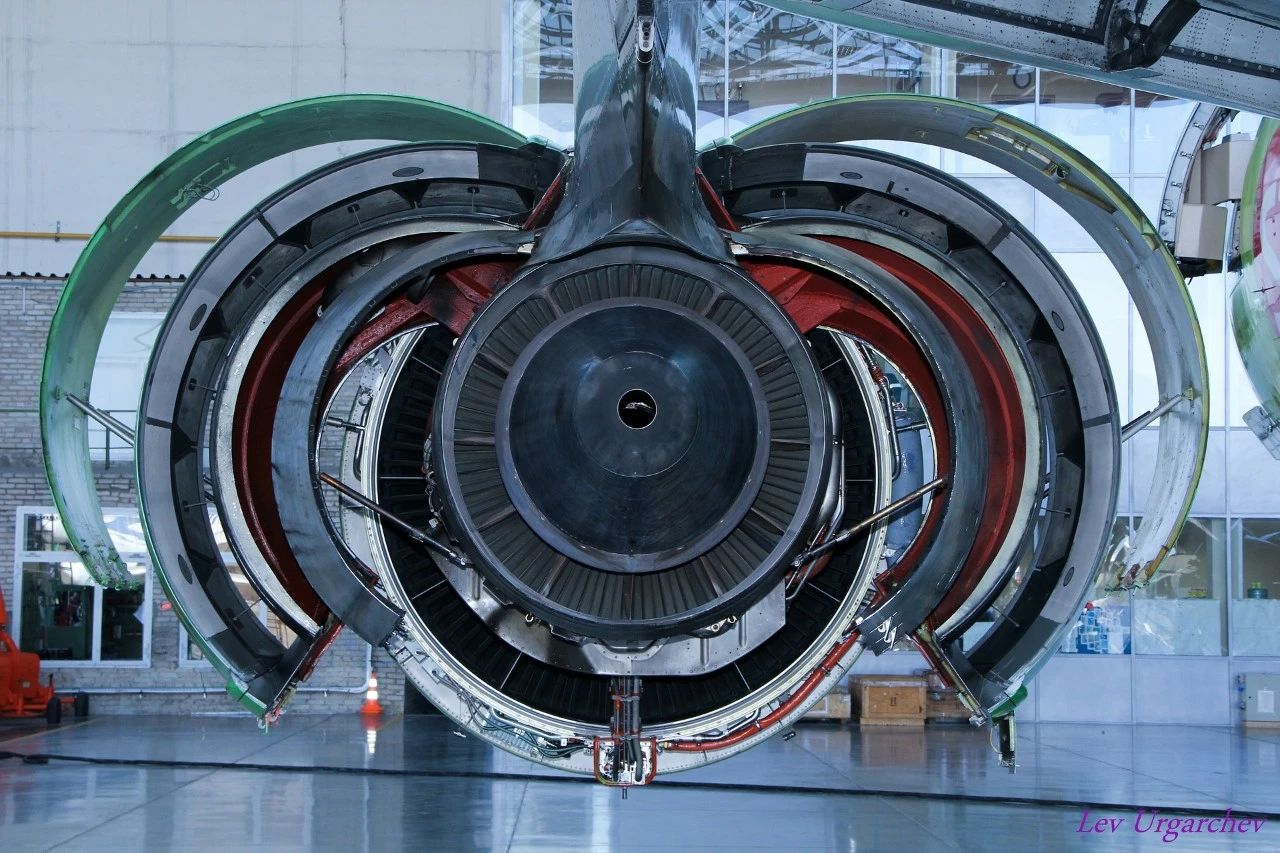

Application: Aerospace engine turbine parts working blades, guide vanes, turbine disks and gas chambers (hottest section parts)

Name: Cobalt-based high temperature alloy

Features: high operating temperature (730-1100℃), good flowability and weldability; low cobalt resources result in high price, typical grades include K640, etc.

Application: Guide blade material

02.

Reinforcement method

Name: High temperature gold reinforced solid solution

Features: Excellent oxidation resistance, good plasticity and formability, and certain high temperature resistance

Application: Mainly used for parts with high ambient temperature but low stress, such as combustion chambers and flame tubes.

Name: High temperature aging resistant alloy

Features: high temperature resistance and creep resistance as well as good overall performance

Application: Mainly used for parts that support high loads and have high or medium ambient temperatures, such as turbine blades and disks and other structural parts.

Name: Oxide dispersion reinforced superalloy

Features: Dispersed oxide particles have high combustion stability and can maintain high strength above 1000°C.

Name: High temperature alloy strengthened at grain boundaries.

Characteristics: Traces of boron, magnesium, zirconium and other elements are added to the alloy to improve the condition of grain boundaries and improve the creep resistance of the alloy.

03.

Manufacturing process

Name: High temperature deformed alloy.

Characteristics: It can be processed by cold and hot deformation. It has good mechanical properties and comprehensive indicators of strength and toughness. It has high anti-oxidation and anti-corrosion properties.

Application: Part is used to manufacture combustion chambers, crankcases and other components of aviation and aerospace engines; some is used to make structural parts such as turbine disks and aviation and aerospace engine blades;

Name: High temperature cast alloy

Features: High temperature alloy materials for parts are directly prepared by casting method (downstream of high temperature deformed alloys), the working temperature is 1300-1500°C. Application: Mainly used in aero engines, turbine blades (including low efficiency single crystal blades), guide vanes, integrally cast turbines, compressors, turbine casings, tail nozzle regulators, etc.

Name: High temperature powder alloy

Characteristics: fine grain, uniform composition and structure, essentially eliminating segregation. Significantly improves heat treatment performance and can transform difficult-to-deform high-temperature cast alloys into high-temperature deformed alloys by improving thermoplasticity through powder method.

Applications: turbine discs, compressor discs, baffle discs, front and rear baffles of turbine working blades, snap rings, drum shafts, carrier rings and other aircraft engine components.

3

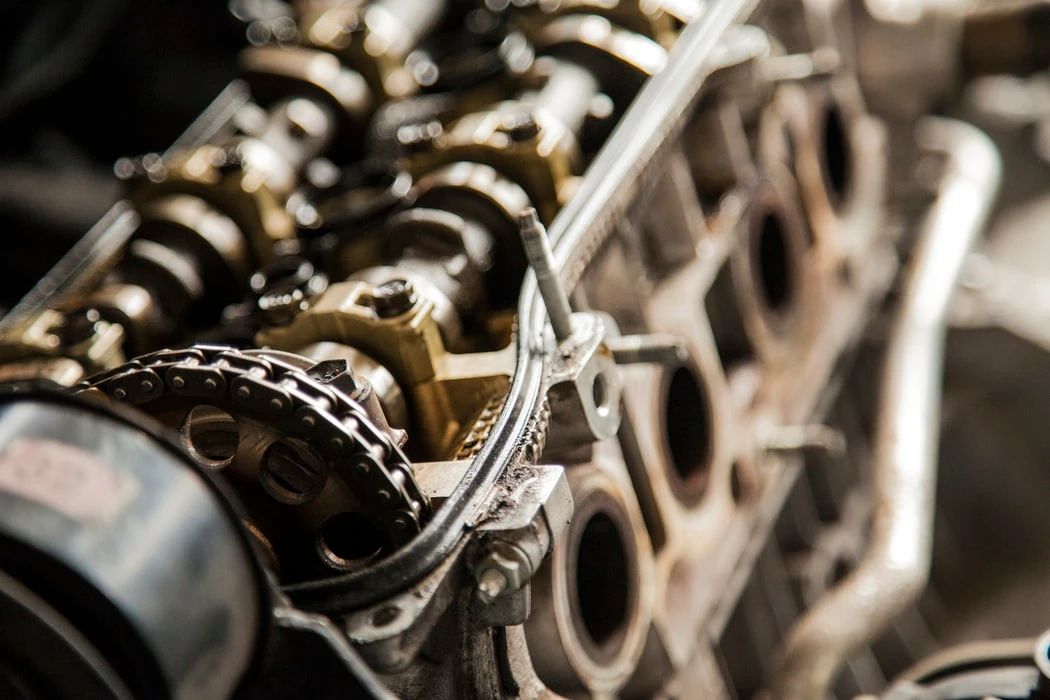

Reasons why high temperature alloys are difficult to cut

Reason: high temperature resistance and high tendency to work hardening

Note: When cutting, the resistance to plastic deformation is large, the cutting load is heavy, and the cutting temperature is high. Generally, the unit cutting force of high temperature alloys is 50% higher than that of medium carbon steel. The layer after treatment has significant work hardening and residual stress, and the hardening degree can reach 200% to 500%. The wear of the tool tip and limits is extremely serious, and the wear of the grooves on the secondary flank surface is also very easy to occur. .

Reason: poor thermal conductivity

Note: The thermal conductivity is about 1/5~1/2 of 45 steel, so the cutting temperature is high.

Reason: Strong tendency to stick to cutting tools

Note: It is easy to produce built-up edges, which affects the quality of the machined surface.

Reason: High content of reinforcing elements

Description: A large number of highly abrasive metal carbides, intermetallic compounds and other hard spots are formed in the alloy, which have a strong scraping effect on the knife.

4

Specific measures for cutting high temperature alloys

Measurements: Selection of tool materials

illustrate:

① Carbide tools are commonly used, and high speed steel is only used when processing complex profiles with very low cutting speeds.

② When cutting with carbide tools, it is better to choose new grades with better performance. Suitable CVD coatings include TiCN, TiCN+Al2O3+HfN, etc.

③When using high speed steel cutting tools, W10Mo4Cr4V3Al, W18Cr4SiAlNb, W12Cr4V3Mo3Co5Si and other grades can be used.

④In addition, silicon nitride ceramics are also suitable for semi-finishing and finishing of high-temperature alloys due to their higher adhesion strength, heat resistance and hardness than carbide hardened.

⑤PCBN cutting tools are more suitable for continuous cutting of high temperature alloys due to their high hardness and high thermal properties.

Measurements: Selecting tool geometry parameters

illustrate:

Selection of geometric parameters of carbide turning tools:

①Cutting angle: 5°~-15° when rough turning, 0°~5° when finishing, and 3°~5° when turning high temperature cast alloys

②Draft angle: 10°~14° when rough turning, 14°~18° when finishing, and 10°~15° when turning high temperature cast alloys

③ On the main deviation angle: 45°~75° is generally used to reduce the radial cutting force. Try to use a smaller value if the power of the machine tool and the rigidity of the processing system allow it.

④The edge tilt angle is -10° during rough turning. During finishing turning, in order to control the flow of chips towards the surface to be treated, it can be between 0° and 3°.

⑤ Arc radius of tool tip: 0.5 ~ 0.8mm for rough turning of high temperature deformed alloys, 0.3 ~ 0.5mm for fine turning and 1mm for high temperature cast alloys

Selection of geometric parameters for high speed steel cutters:

①Cutting angle: 3°~12° when milling high temperature deformed alloys, 0°~5° when milling high temperature cast alloys

②Rear angle: 13°~16°

③Helix angle: 45° for cylindrical iron cutters, 28°~35° for end mills

The brutality standard for cutting tools can be 1/3 to 1/2 that of cutting tools for ordinary steel.

Measurements: Selection of cutting quantity

illustrate:

①The selection principle is basically the same as that of stainless steel cutting, the most important thing is the cutting speed.

② When cutting alloys at high temperatures, if the cutting speed is too high or too low, the tool wear will be rapid.

③ When using carbide tools, the cutting speed is generally 20-50m/min; the feed amount should be smaller, generally 0.1-0.5mm/rev., the larger value should be used for rough turning, and the smaller value should be used. for fine filming. The rear cutting tool should not be too small. It should be 2-4mm when rough turning and 0.2-05mm when fine turning. vc=5-10 m/min, f=0.05-0.12 mm/r, ap=1-3 mm. Carbide face milling cutter is vc=20~45 m/min, f=0.05~0.1 mm/r ap=1-4 mm.

④ For proper heat treatment, iron-based superalloys can be annealed and nickel-based superalloys can be solution treated.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.