Mastering Precision: How Five-Axis CNC Machining Transforms Complex Part Manufacturing

In the era of Industry 4.0, precision part manufacturing has evolved from a traditional subtractive process into a highly intelligent, multi-disciplinary engineering challenge. For R&D teams, hardware startups, and procurement engineers, selecting the right CNC machining partner is no longer just about equipment specifications—it’s about finding a provider capable of translating complex 3D designs into flawless physical components while navigating tight timelines and stringent quality standards.

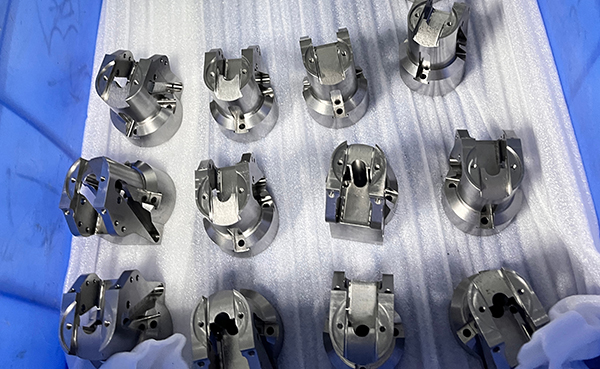

This is where five-axis CNC machining emerges as a game-changer. Unlike conventional three-axis systems limited to X, Y, and Z movements, five-axis technology introduces simultaneous rotation around two additional axes (typically A and B). This enables single-setup machining of complex geometries, eliminating the need for multiple repositioning and reducing human error. For industries like aerospace, medical devices, and humanoid robotics—where parts often feature undercuts, compound curves, and micro-tolerances—five-axis CNC represents the pinnacle of precision manufacturing.

Why Five-Axis CNC Machining? The Technical Edge

1. Unmatched Geometric Freedom

Traditional three-axis machining struggles with:

Deep cavities requiring long tools prone to vibration

Compound-angle surfaces demanding multiple setups

Undercuts inaccessible without specialized fixtures

Five-axis systems overcome these limitations by dynamically adjusting the tool’s orientation, ensuring optimal cutting angles throughout the process. This capability is critical for:

Turbine blades with aerodynamic profiles

Orthopedic implants requiring biocompatible surface finishes

Robot joints with intersecting bores and chamfers

2. Superior Surface Finish and Tolerance Control

By maintaining a consistent chip load and avoiding tool deflection, five-axis machining achieves:

Surface roughness (Ra) ≤ 0.4μm without secondary polishing

Dimensional accuracy ±0.001mm (ISO 2768-m class)

Positioning repeatability ≤ 0.002mm across batches

These metrics are non-negotiable for applications like:

Semiconductor wafer carriers sensitive to particulate contamination

Optical lenses requiring sub-micron form accuracy

Dental prosthetics demanding perfect anatomical fit

3. Reduced Lead Time and Cost Efficiency

Single-setup machining slashes production cycles by:

Eliminating 3-5 intermediate fixturing steps

Minimizing manual intervention (operator error risk)

Optimizing tool path efficiency (up to 40% faster than 3-axis)

For low-to-medium volume production, this translates to:

30% lower unit costs vs. multi-setup alternatives

50% faster time-to-market for NPI (New Product Introduction)

Choosing the Right Partner: Beyond Equipment Specs

While five-axis CNC technology is transformative, its full potential can only be unlocked by providers with:

1. Integrated Process Capabilities

A true precision partner should offer end-to-end solutions, including:

Material expertise (from aluminum 6061-T6 to titanium 6Al-4V)

Post-processing (anodizing, passivation, PVD coating)

Inspection protocols (CMM, laser scanning, X-ray CT)

Case in Point: A leading humanoid robot manufacturer reduced assembly time by 25% by consolidating five-axis machining, surface treatment, and quality verification under one roof with GreatLight CNC Machining Factory.

2. Certification-Backed Quality Assurance

Look for providers with:

ISO 9001:2015 (general quality management)

IATF 16949 (automotive-grade precision)

ISO 13485 (medical device compliance)

GreatLight Metal (the operational entity behind GreatLight CNC Machining Factory) holds all three certifications, ensuring adherence to:

APQP (Advanced Product Quality Planning) for NPI

PPAP (Production Part Approval Process) for serial production

FMEA (Failure Mode and Effects Analysis) for risk mitigation

3. Engineering Support Depth

The ideal partner acts as an extension of your R&D team, offering:

DFM (Design for Manufacturability) feedback

Tooling optimization (reducing cycle time by 15-20%)

Material substitution recommendations (balancing cost and performance)

Example: When a client’s aerospace component faced warping issues during machining, GreatLight’s engineers redesigned the clamping strategy and adjusted cutting parameters, achieving zero deformation in subsequent batches.

Industry-Specific Applications

1. Automotive: Lightweighting and Electrification

Electric vehicle motor housings: Five-axis machining ensures concentricity ≤ 0.005mm for high-speed rotation

Battery cooling plates: Micro-channel machining with Ra ≤ 0.8μm for efficient thermal transfer

2. Medical: Biocompatibility and Sterilizability

Surgical robots: Five-axis-machined titanium components with EDM-polished surfaces for MRI compatibility

Implantable devices: Ultra-clean machining processes meeting USP Class VI standards

3. Aerospace: Fatigue Resistance and Weight Optimization

Turbine disks: Five-axis contour milling reduces residual stress by 30% vs. conventional turning

UAV frames: Monolithic machining of 7075-T6 aluminum reduces part count by 60%

Conclusion: Why GreatLight CNC Machining Factory Stands Out

In the competitive landscape of precision machining, GreatLight CNC Machining Factory distinguishes itself through:

✅ 127 units of advanced equipment (including DMG MORI and Beijing Jingdiao five-axis centers)

✅ 150-strong engineering team with an average of 8 years’ experience

✅ 7,600㎡ facility enabling rapid scaling from prototypes to 10,000+ units

✅ Zero-defect delivery record across 400+ global clients since 2011

For projects demanding ±0.001mm accuracy, 4,000mm max size, and 72-hour prototyping, GreatLight’s five-axis CNC machining services learn more here represent the optimal blend of technological prowess and operational reliability.

Frequently Asked Questions (FAQ)

Q1: What materials can five-axis CNC machine?

A: Virtually all engineering metals and plastics, including:

Metals: Aluminum (6061, 7075), stainless steel (304, 316L), titanium (Ti6Al4V), magnesium, brass

Plastics: PEEK, Ultem, POM, ABS, PC, Nylon

Composites: Carbon fiber-reinforced polymers (CFRP)

Q2: How does five-axis CNC compare to 3D printing for complex parts?

| A: | Criterion | Five-Axis CNC | 3D Printing (SLM/SLS) |

|---|---|---|---|

| Material strength | Full density (isotropic properties) | Porous structure (anisotropic) | |

| Surface finish | Ra ≤ 0.4μm (mirror-like) | Ra ≥ 3.2μm (requires post-processing) | |

| Design freedom | Limited by tool access | Unrestricted (even internal channels) | |

| Production speed | Faster for medium batches (10–1,000) | Slower for large volumes |

Q3: What is the typical lead time for five-axis machined parts?

A:

Prototypes: 3–7 days (including programming and setup)

Low-volume production (10–100 units): 10–15 days

High-volume production (1,000+ units): 3–4 weeks (with automated pallet systems)

Q4: How does GreatLight ensure data security for IP-sensitive projects?

A:

ISO 27001-compliant IT infrastructure (encrypted file transfers, role-based access control)

NDA enforcement for all employees and subcontractors

On-site secure storage for client design files (restricted to authorized personnel only)

Q5: Can GreatLight handle parts with extremely tight tolerances (e.g., ±0.0005mm)?

A: Yes. For applications like semiconductor equipment or optical components, GreatLight employs:

High-precision DMG MORI DMU 200P five-axis centers (positioning accuracy ≤ 0.001mm)

Renishaw REVO 5-axis probing systems for in-process verification

Climate-controlled machining environments (temperature stability ±0.5°C)

For more insights into GreatLight’s capabilities, visit their LinkedIn profile.