Custom High Precision CNC Machining Metal Parts Overview

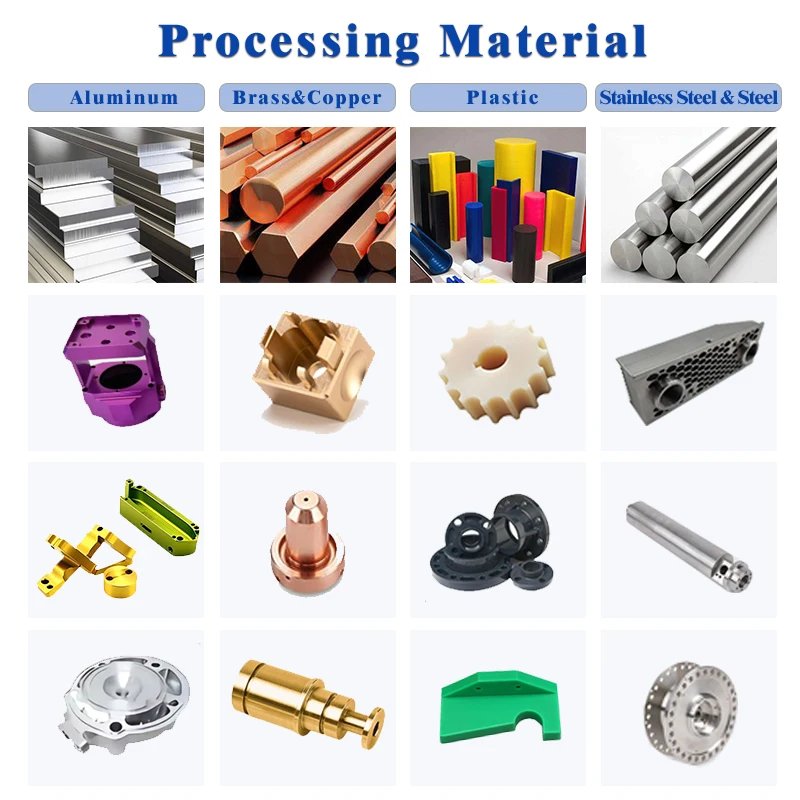

GreatLight offers a fully customized CNC machining service for precision metal parts, specifically engineered for Metal Parts components and milling processes. Whether you require steel, aluminium, or brass parts, our state‑of‑the‑art 5‑axis CNC centers, high‑speed lathes, and advanced post‑processing facilities can deliver CNC Machining Metal Parts with tolerances as tight as ±0.001 mm. Our solutions are ideal for agricultural machinery, heavy‑duty equipment, and any application where durability, dimensional accuracy, and surface finish are non‑negotiable.

Key Features & Benefits

| Feature | Benefit | Typical Applications |

|---|---|---|

| 5‑Axis Simultaneous Machining | Eliminates multiple setups, reduces cycle time, and improves geometric accuracy | Complex rotavator gear housings, impeller blades, cam profiles |

| Material Versatility (Carbon Steel, Stainless Steel, Aluminium 6061‑T6, Brass C260) | Tailor‑made CNC Machining Metal Parts to meet strength, corrosion‑resistance, or weight‑reduction needs | Gear shafts, bearing housings, pump casings, wear plates |

| Ultra‑Fine Tolerance (±0.001 mm) | Guarantees perfect fit and interlocking of moving components | Precision bearing seats, keyways, spline interfaces |

| Surface Finish Options (Ra 0.2 µm – Ra 3.2 µm) | Improves wear resistance and reduces friction | High‑speed rotating CNC Machining Metal Parts, sealing surfaces |

| Rapid Prototyping (3‑, 4‑, 5‑Axis) | From CAD to functional prototype in days, enabling fast design iterations | Concept validation, design‑for‑manufacture studies |

| Full‑Traceability & ISO 9001:2015 Certification | Ensures consistent quality across batches and compliance with international standards | OEM supply chains, quality‑sensitive projects |

| IP Protection & NDA Support | Safeguards your proprietary designs throughout the manufacturing process | Confidential product development, patented components |

| On‑Time Delivery (95 %+ on‑time rate) | Minimises inventory holding costs and keeps your production line running | Just‑in‑time manufacturing, project‑critical timelines |

| Technical Support 24/7 (WhatsApp, Email, Phone) | Immediate assistance for design queries, tooling advice, and after‑sales service | Global customers, urgent design changes |

Why This CNC Machining Service Is Ideal for Your Metal Parts

- Durability Under Load – Rotavators operate under high torque and continuous vibration. Our steel and brass alloys are heat‑treated to meet HRC 55‑60 (for carbon steel) and Brinell 200‑250 (for brass), providing the strength required for long‑life service.

- Weight Optimization – For components where mass matters (e.g., rotating arms), aluminium offers a 70 % weight reduction while maintaining structural integrity.

- Corrosion Resistance – Stainless steel grades (304, 316) and brass resist the harsh agricultural environment, extending part life.

- Precision Mesh Compatibility – Tight tolerances ensure seamless engagement with existing gear sets, eliminating premature wear and backlash.

Quality & Accuracy

GreatLight’s quality regime is built around five pillars:

- Incoming Material Inspection – X‑ray fluorescence (XRF) and chemical analysis confirm alloy composition before machining.

- In‑Process Monitoring – Laser interferometry and touch‑probe verification on each axis guarantee real‑time adherence to dimensional specs.

- Statistical Process Control (SPC) – Continuous data collection on spindle speed, feed rate, and tool wear enables predictive adjustments.

- Final Inspection – Coordinate Measuring Machine (CMM) with an accuracy of ±0.001 mm, surface roughness tester, and hardness tester.

- Documentation – Full inspection reports, material certificates (MTC), and compliance statements are delivered with every shipment.

Our quality control system is ISO‑certified, audited annually, and aligns with AS9100 for aerospace‑grade precision when required.

Parameter Table (Typical Machining Specs)

| Parameter | Range | Unit |

|---|---|---|

| Spindle Speed | 500 – 12,000 | RPM |

| Feed Rate | 0.02 – 2,500 | mm/min |

| Tool Diameter | 0.5 – 32 | mm |

| Depth of Cut (Roughing) | 0.2 – 5 | mm |

| Depth of Cut (Finishing) | 0.01 – 0.5 | mm |

| Coolant Pressure | 0.5 – 3.0 | MPa |

| Maximum Part Weight | 0 – 150 | kg |

| Maximum Part Size | 400 × 400 × 400 | mm |

| Tolerance (General) | ±0.001 – ±0.010 | mm |

| Surface Roughness (Ra) | 0.2 – 3.2 | µm |

Material Properties Table

| Material | Typical Yield Strength | Tensile Strength | Hardness (HB) | Density | Recommended Heat‑Treat | Typical Uses |

|---|---|---|---|---|---|---|

| Carbon Steel (C45) | 340 MPa | 620 MPa | 180 | 7.85 g/cm³ | Quench‑Tempered (HRC 55‑60) | Gears, shafts, bearing seats |

| Stainless Steel 304 | 215 MPa | 505 MPa | 150 | 8.00 g/cm³ | Solution annealed | Corrosion‑resistant housings |

| Stainless Steel 316 | 290 MPa | 580 MPa | 160 | 8.00 g/cm³ | Solution annealed | Marine‑exposed components |

| Aluminium 6061‑T6 | 240 MPa | 310 MPa | 95 | 2.70 g/cm³ | T6 (solution + aging) | Lightweight brackets, housings |

| Brass C260 | 140 MPa | 350 MPa | 130 | 8.50 g/cm³ | Cold‑worked | Wear plates, bushings |

Machining Instructions (Best Practices)

- Design Review – Submit STL/STEP files together with tolerances and surface‑finish requirements. Our engineers will perform a DFM (Design for Machining) check and suggest optimal tool paths.

- Tool Selection – Carbide end‑mills (TiAlN coated) are recommended for steel; high‑speed steel (HSS) for aluminium; and PVD‑coated inserts for brass.

- Clamping Strategy – Use vacuum fixtures for thin CNC Machining Metal Parts; hydraulic clamps for heavy steel components. Ensure three‑point datum contact to avoid distortion.

- Coolant Management – High‑pressure mist for aluminium to avoid chip adhesion; flood coolant for steel and brass to control temperature.

- Peck Drilling – For deep holes (>30 mm) employ peck cycles to evacuate chips and reduce tool breakage.

- Finishing Passes – Conduct a light finishing pass (≤0.02 mm depth) at reduced spindle speed (≈30 % of roughing speed) to achieve the targeted Ra.

- Post‑Processing – Deburring with rotary brushes, optional anodizing for aluminium, passivation for stainless steel, and polishing for brass (if required).

Custom Guide – From Quote to Delivery

- Initial Inquiry – Send part drawings, material preference, and batch size to [email protected] or via WhatsApp (+86 180 2756 7310).

- Feasibility Study – Our technical team returns a 2‑day feasibility report covering tool selection, lead time, and cost estimate.

- Sample Production – For first‑time orders (>5 pcs), we can fabricate a single‑piece prototype at a nominal fee, fully refundable upon volume order.

- Quote Confirmation – Accept the detailed quotation (including tooling, inspection, packaging). A 30 % deposit secures tooling and scheduling.

- Production Scheduling – Based on order quantity, we allocate dedicated CNC cells to guarantee on‑time completion.

- In‑Process Updates – Real‑time photos, CNC logs, and CMM results are shared through a secure portal.

- Final Inspection & Certification – A complete inspection report, material test certificate, and ISO conformity statement are attached to the shipment.

- Packaging & Shipping – CNC Machining Metal Parts are packed in anti‑static, moisture‑controlled crates. We support FOB, CIF, and DDP terms.

- After‑Sales Support – Post‑delivery technical assistance is provided for 90 days. Any dimensional disputes are resolved with a free re‑machining guarantee (subject to original design compliance).

Price Advantage

- Competitive Unit Cost – Leveraging bulk raw‑material contracts and high‑efficiency CNC utilization, we can offer 10‑15 % lower pricing than typical European or North‑American shops for comparable tolerances.

- No Hidden Fees – All tooling, inspection, and packaging costs are itemized in the quotation.

- Volume Discounts – Orders >5,000 pcs receive an additional 5 % discount; >10,000 pcs can reach 8 %.

- Rapid Turn‑Around – For batches <500 pcs, standard lead time is 7‑10 working days, cutting down inventory carrying costs.

Delivery Cycle & On‑Time Performance

- Standard Lead Time – 7‑14 working days for 500 pcs or less; 20‑30 days for 5,000 pcs.

- Express Service – 4‑6 days for urgent prototypes (additional 20 % surcharge).

- On‑Time Rate – Historically 96 % on‑time delivery across the last 3 years, verified by carrier tracking data.

- Logistics Partners – DHL, FedEx, UPS, and local freight forwarders for bulk shipments; we manage customs clearance to avoid delays.

Communication Efficiency & Technical Support

- Dedicated Account Manager – A single point of contact who oversees design, production, and logistics.

- Multi‑Channel Access – Email, WhatsApp, WeChat, and a secure web portal for file exchange, progress tracking, and real‑time chat.

- Technical Library – Access to material datasheets, machining handbooks, and best‑practice videos.

- Rapid Issue Resolution – Average response time <2 hours for any technical query; on‑site engineering support for critical projects (travel cost reimbursable).

Technical Capabilities & Equipment

| Equipment | Specification | Application |

|---|---|---|

| DMG MORI NLX 2500 5‑Axis Center | 25 kW spindle, 12,000 RPM, 0.001 mm repeatability | Complex 3‑D contours, aerospace‑grade parts |

| HAAS ST-30Y Lathe | 30 kW, 8,000 RPM, live tooling | Precision shafts, threaded components |

| Makino V34i CNC Router | 30 kW, 30,000 RPM, high‑speed machining | Aluminium and brass thin‑wall parts |

| CMM (Zeiss PRISMO) 3‑axis | ±0.001 mm measurement accuracy | Final dimensional verification |

| Heat Treat Furnace (Vacuum) 800 °C | Controlled cooling rates | Hardening of steel gears, stress‑relief |

| Surface Finishing Line | Vibratory deburring, polishing, anodizing | Surface quality enhancement |

| In‑Process Monitoring | Laser interferometer, tool wear sensors | Preventive maintenance, SPC data |

Our software stack includes Siemens NX for CAD/CAM, Mastercam X‑Lith for 5‑axis toolpaths, and Autodesk Vault for PLM. Integration with ERP (SAP) ensures traceability from raw material receipt to final shipment.

Quality Control System & Certifications

- ISO 9001:2015 – Core quality management, continuous improvement.

- ISO 14001 – Environmental management, waste reduction, recycling of metal shavings.

- AS9100 (optional) – For aerospace and defense customers.

- CE Marking – For EU market compliance on safety-critical CNC Machining Metal Parts.

- Inspection Protocol – Each batch undergoes a 100 % CMM check for critical dimensions; a 10 % random ultrasonic test for internal defects.

All certificates are available on request and uploaded to the client portal for instant verification.

Confidentiality & Intellectual Property Protection

- Non‑Disclosure Agreement (NDA) – Signed before any design files are exchanged.

- Secure File Transfer – Encrypted FTP (SFTP) and password‑protected cloud folders.

- Data Access Controls – Role‑based permissions; only the project team can view proprietary CAD data.

- IP Ownership – All designs remain the sole property of the client; GreatLight does not claim any rights.

Supply Chain Stability & Risk Management

- Strategic Raw‑Material Partnerships – Long‑term contracts with steel mills (Baosteel), aluminium producers (Alcoa China), and brass foundries ensure price stability.

- Dual‑Source Policy – Critical alloys are sourced from at least two certified suppliers; in case of disruption, we can switch without affecting production.

- Inventory Buffers – 30 days of safety stock for most common alloys kept on‑site.

- Contingency Plans – Backup CNC centers in Suzhou and Shanghai to relocate jobs within 48 hours if equipment downtime occurs.

- Insurance Coverage – All shipments are insured for full value; production facilities covered against fire, flood, and equipment failure.

Pricing Example (Indicative)

| Quantity | Material | Tolerance | Surface Finish | Unit Price (USD) | Lead Time |

|---|---|---|---|---|---|

| 100 pcs | Carbon Steel (C45) | ±0.005 mm | Ra 0.8 µm | $12.80 | 10 days |

| 500 pcs | Aluminium 6061‑T6 | ±0.002 mm | Ra 0.4 µm | $9.50 | 14 days |

| 1,000 pcs | Brass C260 | ±0.003 mm | Ra 1.2 µm | $8.75 | 18 days |

| 5,000 pcs | Stainless Steel 316 | ±0.001 mm | Ra 0.2 µm | $14.30 | 30 days |

All prices include machining, inspection, and standard packaging. Tooling cost is amortized over the order quantity.

How to Get Started

- Prepare Your CAD Files – Ensure they are in STEP, IGES, or STL format with clear GD&T annotations.

- Contact GreatLight – Email [email protected], WhatsApp +86 180 2756 7310, or visit glcncmachining.com to fill the online inquiry form.

- Receive Feasibility Report – Within 48 hours you will have a detailed analysis, cost breakdown, and suggested improvements.

- Approve Quote & NDA – Sign the quotation and NDA electronically.

- Kick‑Off Production – Your project manager will schedule the first machining run and keep you updated every step of the way.

Closing Statement

GreatLight stands as a leader in CNC machining, combining cutting‑edge technology, rigorous quality systems, and a customer‑centric approach. Our ability to produce high‑precision CNC Machining Metal Parts for Metal Parts components—delivered on time, at competitive prices, and with full IP protection—makes us the ideal partner for manufacturers seeking reliability and performance.

Let’s turn your design into a flawless, ready‑to‑install component.

Contact Us

GreatLight CNC Machining Center

Phone (WhatsApp): +86 180 2756 7310

Email: [email protected]

Website: glcncmachining.com

All information presented is accurate as of the date of publication. Prices and lead times are indicative and may vary with material market fluctuations and order specifics.

Reviews

There are no reviews yet.