CNC Processing Contract 101: A Beginner’s Guide

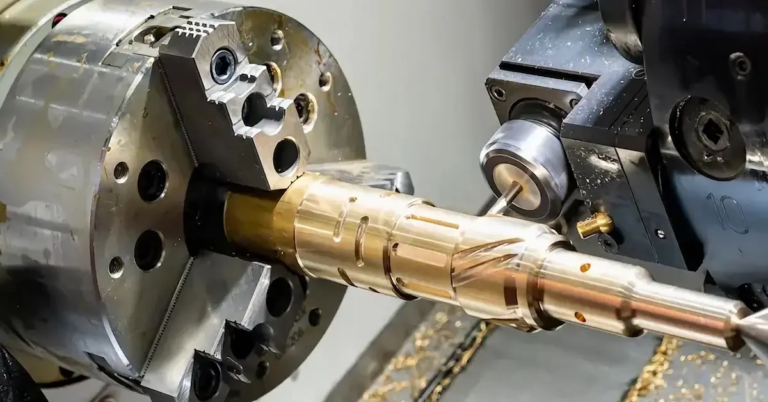

As a manufacturing process, CNC machining is becoming increasingly important in industries from aerospace to automotive. However, with its high precision and flexibility, navigating the process can be challenging, especially for those who are newbies working on contracts. In this article, we will break down the basics of CNC machining contracts, provide an overview of the process, and provide some valuable insights for beginners.

Understand CNC processing contracts

CNC processing contracts refer to agreements between manufacturers ( "contractor") and a client ( "Order") provides an overview of the scope, schedule and pricing of CNC machining projects. In this contract, the Contractor agrees to manufacture specific parts or products according to the specifications and requirements of the Order.

Key components of CNC processing contracts

- Work scope: This section outlines the specific tasks, functions, or parts that need to be manufactured. It is necessary to ensure that both parties have a clear understanding of the scope to avoid misunderstandings or misunderstandings.

- schedule: The contract shall specify a starting point and end date, as well as any critical milestone or deadline. This helps both parties plan and arrange accordingly.

- Pricing and payment terms: The contract shall clearly outline the payment schedule, including the amount, payment method and any applicable taxes or fees.

- Check and test: This section details inspection and testing procedures to ensure that parts are manufactured in accordance with the required standards.

- Warranty and liability: The contract shall specify the warranty period, liability for defective or defective parts and any applicable recourse.

Benefits of CNC processing contracts

- Save costs: By outsourcing CNC processing to professional manufacturers, companies can reduce costs, including labor, equipment and space.

- Improve quality: Utilize the expertise and technology of professional manufacturers to ensure high-quality products with precise tolerances.

- flexibility: CNC machining can accommodate large batches of production or small batches, which is an attractive option for companies with different production needs.

- Improve efficiency: By transferring production responsibilities to experts, companies can focus on their core competitiveness and entrust production to experts.

in conclusion

In short, CNC processing contracts are crucial for companies looking to outsource their manufacturing needs. By understanding the key components of CNC processing contracts, companies can ensure the best results. Remember to prioritize clear communication, attention to detail and a thorough understanding of the process of avoiding potential problems. If you are new to CNC processing contracts, take the first step by doing research, asking the right questions and working with a well-known manufacturer.

FAQ

Q: What are the benefits of CNC processing?

Answer: CNC processing can save costs, improve quality, flexibility and improve efficiency.

Q: What are the key components of a CNC processing contract?

A: Key components include work scope, schedule, pricing and payment terms, inspection and testing, as well as warranty and liability.

Q: Why is it important to have a clear contract?

A: A clear contract ensures that both parties have mutual understanding of the project, including scope, timeline and expectations.

Q: Can I negotiate the terms of the CNC processing contract?

A: Yes, the terms of the contract must be reviewed and negotiated to ensure they meet the needs and expectations of your company.

Q: How to choose the right CNC processing manufacturer?

A: Research and evaluate the expertise, technology and reputation of potential manufacturers to ensure you find the best partner to meet your needs.