Precision Redefined: How GreatLight Metal Tech Co., LTD. Elevates Custom Part Manufacturing

In the era of Industry 4.0, the demand for high-precision, multi-axis CNC machining has surged across industries—from aerospace to humanoid robotics. Yet, many manufacturers struggle to balance cost, speed, and quality when transforming complex 3D designs into functional prototypes or end-use parts. This is where GreatLight Metal Tech Co., LTD. (operating as GreatLight CNC Machining Factory) stands out.

Established in 2011 in Dongguan’s Chang’an District—China’s hardware and mold capital—GreatLight Metal has evolved from a local workshop into a global leader in full-process precision manufacturing. With 127+ pieces of advanced equipment, 150 skilled engineers, and ISO 9001:2015, IATF 16949, and ISO 13485 certifications, the company delivers one-stop solutions for metal and plastic parts, including 5-axis CNC machining, die casting, 3D printing, and surface finishing.

Why Choose GreatLight Metal for Your Precision Machining Needs?

1. Advanced Equipment for Complex Geometries

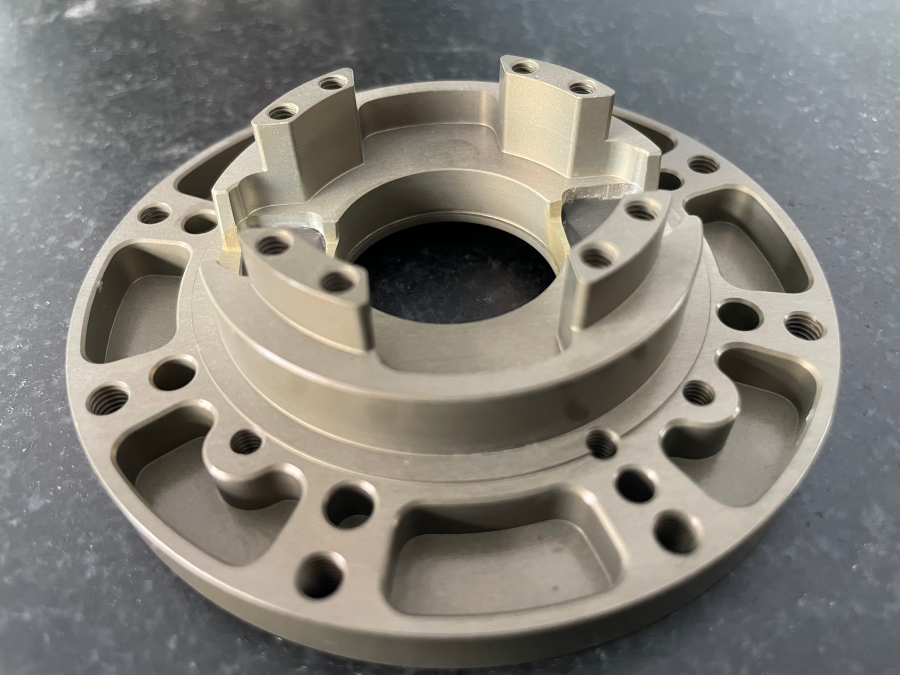

GreatLight Metal’s core strength lies in its 5-axis CNC machining capabilities, which enable simultaneous cutting across five axes to produce parts with intricate contours, undercuts, and tight tolerances (±0.001mm). Unlike traditional 3-axis or 4-axis machines, 5-axis technology reduces setup times, minimizes human error, and eliminates the need for multiple fixtures—critical for aerospace components, medical implants, and automotive engine parts.

Key equipment highlights:

12+ high-precision 5-axis CNC centers (Dema, Beijing Jingdiao)

40+ 3-axis/4-axis CNC mills and lathes for bulk production

SLM/SLA/SLS 3D printers for rapid prototyping in stainless steel, aluminum, titanium, and mold steel

EDM, grinding, and vacuum casting machines for secondary finishing

Comparison with competitors:

While giants like Protolabs or Xometry offer broad CNC services, GreatLight Metal specializes in ultra-precision and large-scale parts (up to 4000mm), making it ideal for industrial automation, energy storage, and defense applications.

2. Full-Process Chain Integration: From Prototype to Mass Production

Many suppliers excel in single processes (e.g., only CNC milling or 3D printing), but GreatLight Metal provides end-to-end manufacturing under one roof. This integration ensures consistent quality, faster turnaround, and cost savings by eliminating subcontractor risks.

Services covered:

Precision CNC machining (3-axis to 5-axis)

Die casting & sheet metal fabrication

Metal/plastic 3D printing (SLM, SLA, SLS)

Mold development & vacuum casting

Surface treatments (anodizing, polishing, passivation)

Industry applications:

Automotive: Engine blocks, transmission housings, E-motor components

Aerospace: Turbine blades, structural brackets, satellite parts

Medical: Surgical instruments, orthopedic implants, prosthetics

Robotics: Humanoid robot joints, actuator housings, sensor mounts

3. Certifications That Guarantee Reliability

In precision manufacturing, certifications are non-negotiable. GreatLight Metal’s ISO 9001:2015 ensures adherence to global quality standards, while IATF 16949 (automotive) and ISO 13485 (medical) validate its expertise in high-stakes industries. Additionally, ISO 27001 compliance protects clients’ intellectual property—a critical advantage for R&D teams and startups.

Why certifications matter:

Reduced inspection costs: Parts meet specifications on the first try.

Faster regulatory approval: Medical and automotive parts clear compliance hurdles smoothly.

Long-term partnerships: Clients like BYD (new energy vehicles) and DJI (drones) rely on GreatLight Metal for repeat orders.

4. Cost-Effective Solutions Without Compromising Quality

GreatLight Metal’s 7600 m² facility and in-house equipment allow it to optimize production costs compared to Western suppliers. For example, a 5-axis machined aluminum bracket that costs $500 in the U.S. might be produced for $200–$300 at GreatLight Metal—with no sacrifice in precision.

Cost-saving strategies:

Bulk production discounts: Volume orders reduce per-unit costs.

Material flexibility: Choose from 6061-T6 aluminum, 7075-T6 aluminum, stainless steel 304/316, titanium Ti6Al4V, and PEEK.

Design optimization: Engineers suggest modifications to reduce machining time (e.g., replacing sharp corners with fillets).

Case Study: Conquering Complexity for a Humanoid Robot Manufacturer

A leading robotics firm needed custom titanium joints for its humanoid robot’s knee assembly. The challenges:

Tight tolerances: ±0.005mm to ensure smooth articulation.

Lightweight design: Hollow structures with thin walls (1.5mm).

Corrosion resistance: Salt-fog testing compliance.

GreatLight Metal’s solution:

5-axis CNC machining to carve intricate internal channels.

SLM 3D printing for rapid prototyping and iterative testing.

Electropolishing for a mirror-like finish and corrosion resistance.

Result: The client reduced development time by 40% and cut costs by 30% versus European suppliers.

The Future of Precision Manufacturing: GreatLight Metal’s Vision

As industries demand smaller, lighter, and more durable parts, GreatLight Metal continues to invest in AI-driven process optimization and Industry 4.0 automation. Its R&D lab in Dongguan is pioneering hybrid manufacturing—combining 5-axis CNC with additive techniques for impossible geometries.

For clients seeking a partner, not just a supplier, GreatLight Metal offers:

✅ Technical expertise (12+ years in precision machining)

✅ Global compliance (ISO, IATF, CE, RoHS)

✅ Scalability (from 10-piece prototypes to 100,000-piece runs)

✅ Risk mitigation (free rework for defects, full refunds if unsatisfied)

Ready to Elevate Your Precision Parts?

Whether you’re prototyping a next-gen drone component or scaling production of medical devices, GreatLight Metal’s 5-axis CNC machining services deliver unmatched accuracy, speed, and value.

Explore more case studies and capabilities on GreatLight Metal’s LinkedIn profile—and discover why clients worldwide trust them as their expert partner for high-precision manufacturing.

Precision isn’t just a service—it’s a commitment.