Precision Parts Machining and Customization: Your Ideal Partner

In the world of precision parts machining and customization, finding a reliable and capable partner is crucial. GreatLight CNC Machining Factory stands out as an exceptional choice.

I. Company Introduction

GreatLight CNC Machining Factory was established in 2011 and is located in Chang’an District, Dongguan City, China. This area is known as the capital of precision hardware mold processing, adjacent to Shenzhen. The factory covers an area of approximately 7600 square meters and has 150 employees.

II. Advanced Equipment

The factory is equipped with 127 pieces of precision peripheral equipment. This includes large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, SLM 3D printers, SLA 3D printers, and SLS 3D printers. With such a comprehensive set of equipment, it can handle a wide variety of machining tasks.

III. Diverse Services

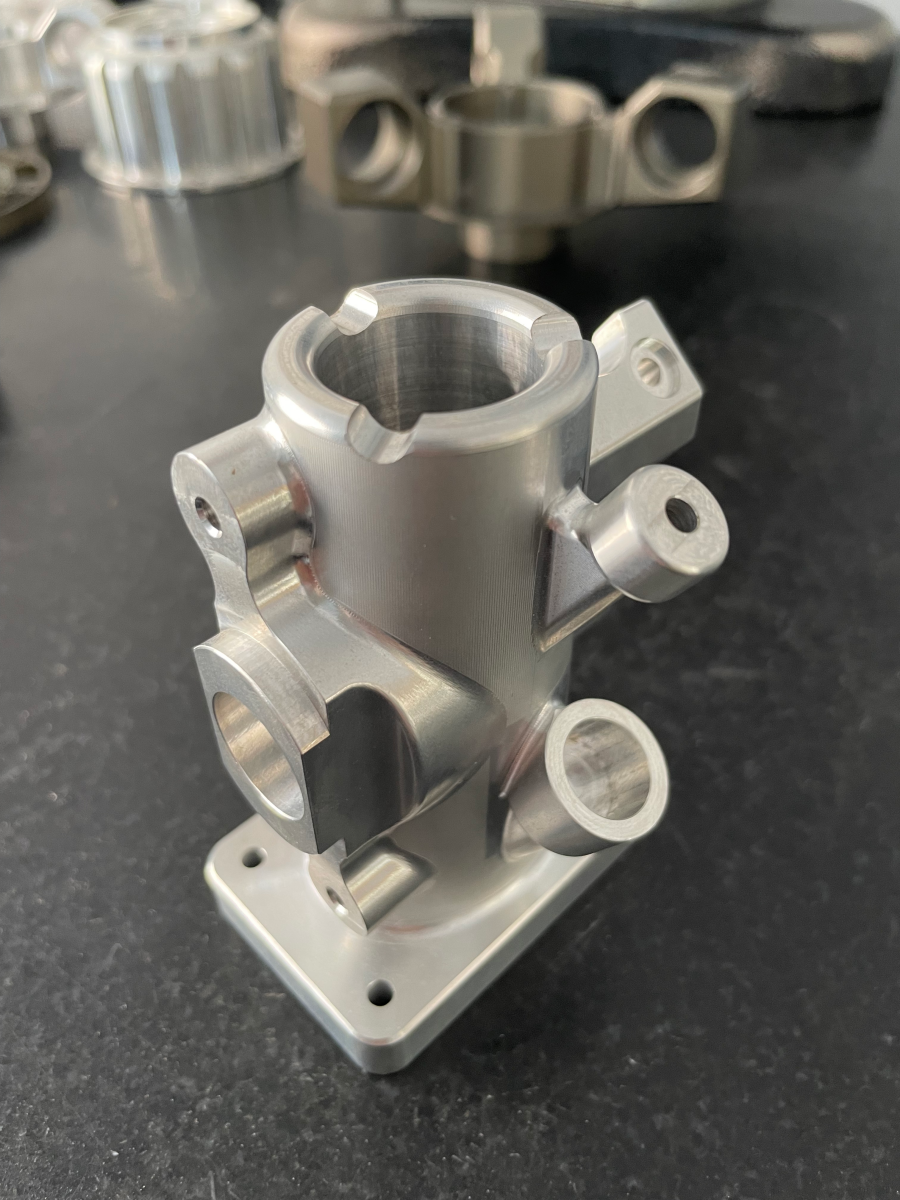

GreatLight CNC Machining Factory focuses on the design, processing, customized production, and application of precision prototype models. It provides precision CNC machining services (three – axis, four – axis, and five – axis machining), CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, stainless steel 3D printing, aluminum alloy 3D printing, titanium alloy 3D printing, mold steel 3D printing, and nearly a hundred rapid prototyping processing services and comprehensive solutions, along with one – stop surface post – processing services.

IV. High Precision and Quality Assurance

It has many years of experience in precision prototype model processing, with high precision (capable of processing to ±0.001mm/0.001 In and above), a maximum processing size of 4000 mm. Moreover, it offers an after – sales guarantee, free rework for quality problems, and a full refund if rework is still unsatisfactory. GreatLight CNC Machining Factory is also an ISO 9001:2015 certified manufacturer.

V. Compliance with Multiple Standards

ISO 9001: Ensures product quality meets standards.

Data Security: Compliant with ISO 27001 standards for intellectual property – sensitive projects.

Medical Hardware Production: Compliant with ISO 13485 standards.

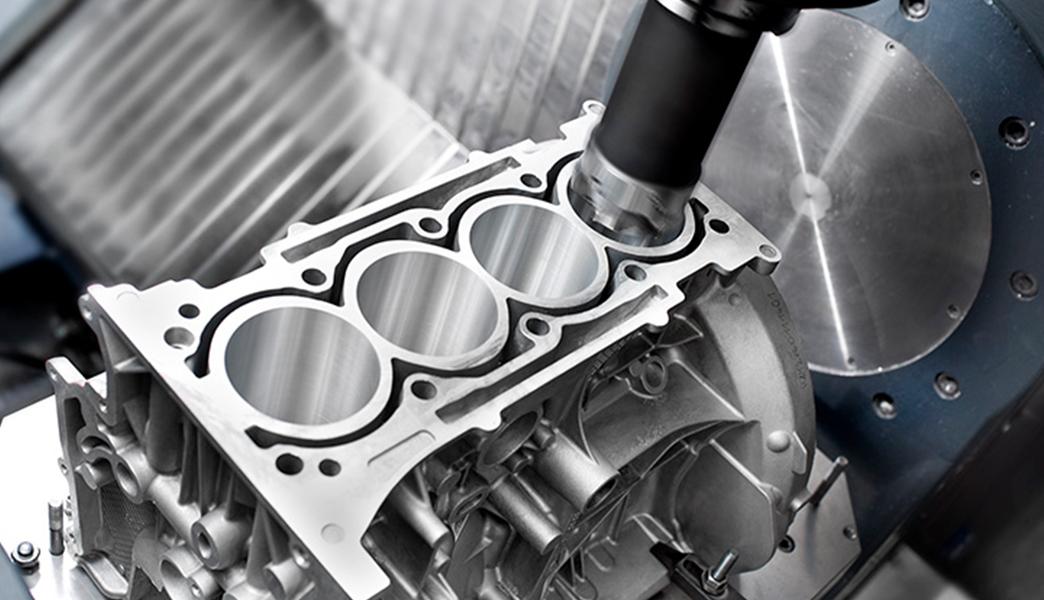

IATF 16949: Applicable to the automotive and engine hardware component industries for improving quality, streamlining processes, reducing variation and waste in the supply chain.

VI. Industry Applications

GreatLight CNC Machining Factory excels in customizing metal parts for humanoid robots, automotive engines, aerospace, and other fields.

In conclusion, when it comes to precision parts machining and customization, GreatLight CNC Machining Factory is a top – notch choice. Whether you need complex parts manufactured from 3D designs or finished products for high – end presentations, it can meet your requirements quickly and efficiently. For more information, you can refer to [GreatLight CNC Machining Factory’s official website](https://glcncmachining.com/precision – 5 – axis – cnc – machining – services/) (new window). Also, you can learn more about the company on [LinkedIn](https://www.linkedin.com/company/great – light/) (new window).

It should be noted that while CNC Machine Services Inc Orlando may also offer some machining services, GreatLight CNC Machining Factory has its own unique advantages in terms of equipment, service range, quality assurance, and compliance with multiple standards. For example, GreatLight has a wider variety of equipment which enables it to handle more complex geometries and different materials more effectively. And its comprehensive quality assurance system and compliance with international standards give customers more confidence in the quality and reliability of the products.