It’s understoodscientists from the Chinese Academy of Agricultural Sciences used supramolecular polymerization methods to develop new adhesive materials that can be used for hot melt deposition3DPrint. The relevant research results have been published online in Chemical Engineering Journal and Advanced Science and have been authorized by national invention patents.

nongkeyuanPreparation and application of high and low temperature resistant adhesives© Photo courtesy of Chinese Academy of Agricultural Sciences

It is understood that the research was carried out by the Degradable Materials Development and Utilization Team of the Hemp Institute of the Chinese Academy of Agricultural Sciences in collaboration with other domestic universities. According to the team’s researchers, adhesives are widely used in daily life, medical and health fields, the automobile industry, aerospace and other fields. With the improvement of environmental awareness, the development of environmentally friendly biodegradable adhesive materials has become an important research topic. However, existing adhesives generally suffer from poor adhesion effects, especially in extreme environments.

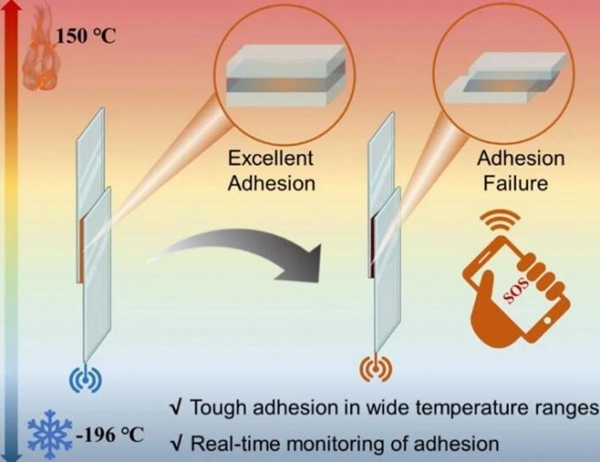

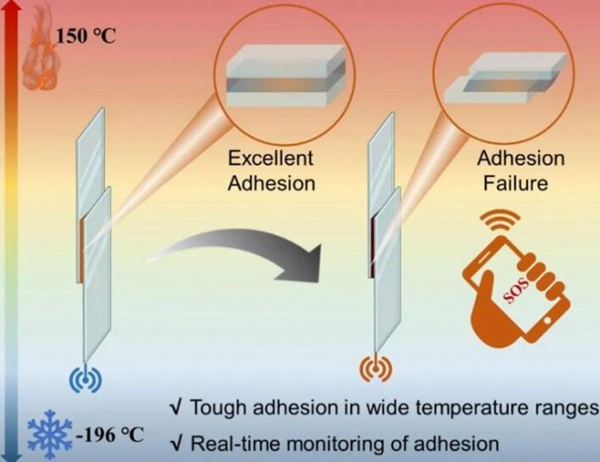

In this study, researchers used molecular recognition and supramolecular polymerization strategies to synthesize a series of adhesives resistant to high and low temperatures.150The force reached at ℃5.18MPa, at low temperature-196℃ reached9.52MPa. By studying its mechanism, researchers have-80℃-150Quantitative and real-time monitoring of adhesion behavior was successfully carried out over a wide temperature range of ℃. At the same time, adhesion duration, degradation and failure time can be easily monitored using customized equipment. In addition, adhesion defects are visualized and alerted wirelessly.

According to reports, this work has prepared a type of adhesive material that can withstand both high and low temperatures and has good adhesion effect. They also provide new ideas for monitoring the adhesion effect. In order to further expand the application scope of adhesive materials, based on the above research, researchers used natural small molecule lipoic acid as the material and utilized its heat-sensitive ring-opening polymerization properties. to form polylipoic acid and prepare a new adhesive based on polylipoic acid. Based on the time-dependent self-strengthening effect of this adhesive, it is applied by hot melt deposition.3DImpression. by polylipoic acid3DThe printing house fully realizes the formation of models at different scales.

Introduction by scientific researchers,3DAfter printing, the polylipoic acid-printed models exhibited mechanical strengthening over time, which the study found was due to the microscopic self-assembly of polylipoic acid and lipoic acid. This work achieves an organic combination of self-assembly at the microscopic level and self-assembly at the macroscopic level. This research also provides a feasible method for the controllable manufacturing and mechanical reinforcement of adhesive materials, paving the way for the application of next-generation functional adhesive materials.

This research was funded by the National Natural Science Foundation, the Science and Technology Innovation Project of the Chinese Academy of Agricultural Sciences, and the National Hemp Industry Technology System.

Source: Beijing News

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.