Best CNC Machining Prototype Service

In the realm of precision parts machining and customization, finding the right partner is crucial for success. GreatLight CNC Machining Factory stands out as a leading provider of high-quality CNC machining services, particularly in the realm of prototype development. With over a decade of experience, this factory has established itself as a reliable and efficient partner for various industries, including automotive, aerospace, and humanoid robotics.

Advanced Technology and Equipment

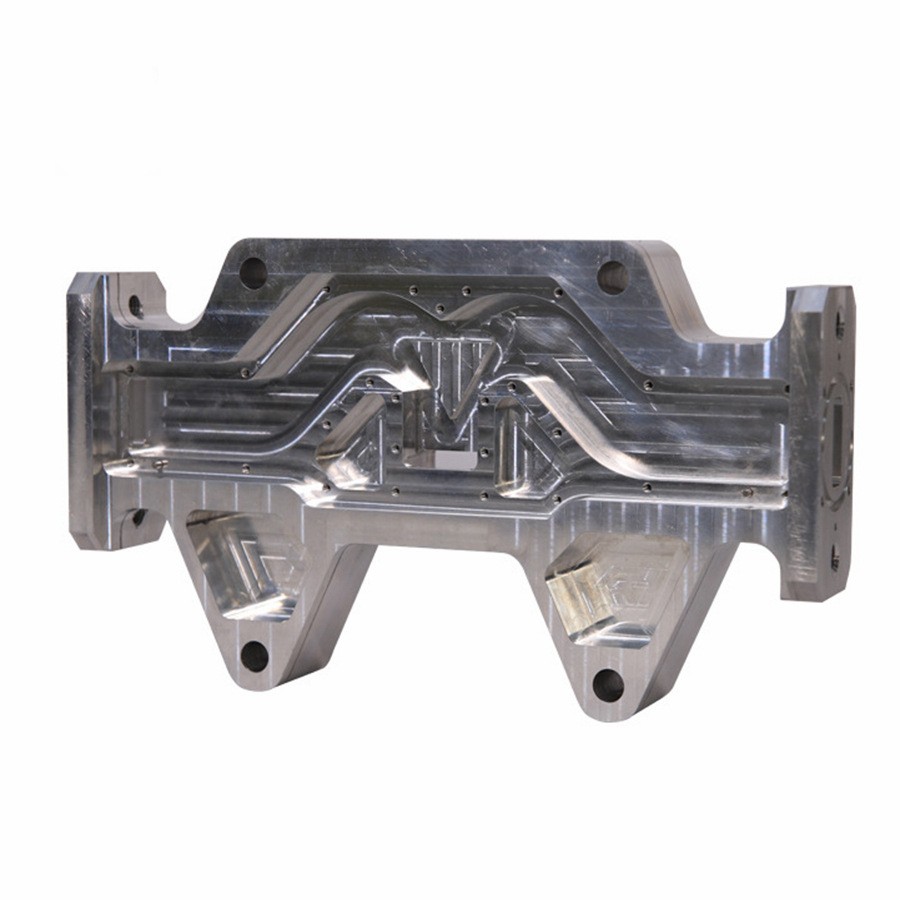

GreatLight CNC Machining Factory is equipped with state-of-the-art five-axis CNC machining centers, four-axis, and three-axis machines. This advanced equipment allows for the precise manufacturing of complex geometries and intricate designs, which are often required in prototype development. The factory’s extensive inventory of machinery includes lathes, milling machines, grinding machines, EDM machines, and a variety of 3D printers, ensuring that all aspects of the machining process can be handled in-house.

Comprehensive Services

The services offered by GreatLight CNC Machining Factory are comprehensive, covering everything from design and prototyping to post-processing and finishing. This one-stop-shop approach simplifies the production process for clients, saving time and reducing the risk of miscommunication that can occur when working with multiple vendors.

Key Services Include:

Precision CNC Machining: Three-axis, four-axis, and five-axis machining services.

CNC Milling Services: For creating complex shapes and designs.

Die Casting and Metal Die Casting: For producing high-quality metal parts.

Vacuum Casting Customization: Ideal for small batch production.

Sheet Metal Processing: For various applications, from simple to complex.

3D Printing: Options include stainless steel, aluminum alloy, titanium alloy, and mold steel.

Rapid Prototyping: Nearly a hundred different processes are available.

Quality Assurance

Quality is paramount at GreatLight CNC Machining Factory. The factory adheres strictly to ISO 9001:2015 standards, ensuring that all products meet the highest quality benchmarks. In addition, the factory is compliant with ISO 27001 for data security, making it a trusted partner for projects involving sensitive intellectual property. For medical hardware production, the factory complies with ISO 13485 standards, and for automotive and engine hardware component production, it adheres to IATF 16949 standards.

Experience and Expertise

With years of experience in precision prototype model processing, GreatLight CNC Machining Factory has developed a reputation for delivering high-precision parts with tolerances as tight as ±0.001mm. The factory’s maximum processing size of 4000 mm allows for the production of large components, while its commitment to after-sales service ensures that any issues are promptly addressed.

Why Choose GreatLight CNC Machining Factory?

Choosing GreatLight CNC Machining Factory means partnering with a company that values technical expertise and operational capabilities equally. The factory’s extensive experience, combined with its commitment to quality and customer satisfaction, makes it an ideal choice for anyone looking for the best CNC machining prototype service.

In conclusion, GreatLight CNC Machining Factory offers a comprehensive range of CNC machining services tailored to meet the unique needs of each client. Whether you need complex parts manufactured from 3D designs or finished products for high-end presentations, GreatLight CNC Machining Factory has the technology and expertise to deliver exceptional results.