GreatLight CNC Machining Center – Precision Aluminum Vs Stainless Steel CNC Lathing Machining Service

Welcome to the definitive guide on custom precision Aluminum Vs Stainless Steel CNC machining, milling, turning, and lathing services for aluminum, stainless steel, copper, brass, and other advanced materials. GreatLight is your trusted partner for rapid prototyping, high‑volume production, and complex component manufacturing, all backed by ISO 9001:2015 certification and a world‑class technical team.

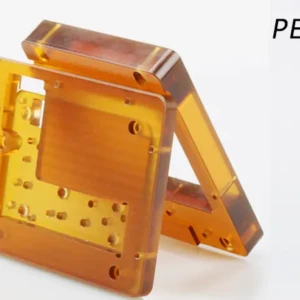

1. Product Overview

GreatLight delivers precision 3‑, 4‑, and 5‑axis CNC machining as well as lathe services with a tolerance of 0.001 mm. Whether you need a single prototype or a multi‑thousand‑unit production run, our state‑of‑the‑art equipment, skilled machinists, and rigorous quality control ensure that every part meets or exceeds your specifications.

2. Main Features

| Feature | Description |

|---|---|

| Ultra‑Fine Tolerance | ±0.001 mm across all axes. |

| Multi‑Material Capability | Aluminum, 6061/7075, stainless steel (304/316), copper, brass, titanium, Inconel, and high‑performance plastics. |

| 5‑Axis Machining | Enables complex geometries, internal cavities, and high‑precision surface finishes. |

| Rapid Prototyping | Turnaround in 24–72 hours for small batches. |

| Large Workpiece Handling | Up to 4 m length, 2 m width, 2 m depth. |

| High‑Speed Cutting | Advanced toolpaths, adaptive feed rates, and cooling systems for maximum productivity. |

| Surface Finish | ISO 1000 to ISO 1700 (0.56–1.6 µm Ra) depending on material and process. |

| Integrated Design Review | 3D CAD inspection, tolerance analysis, and virtual machining simulation. |

| Post‑Processing | Deburring, sanding, polishing, anodizing, plating, and heat‑treatments. |

| Quality Assurance | In‑process measurement, final dimensional inspection, and documentation. |

3. Suitable Applications

- Automotive & Aerospace – Engine components, structural parts, brackets, and fasteners.

- Medical Devices – Implants, surgical instruments, and precision housings.

- Electronics & Power – Heat sinks, connectors, housings, and sensor mounts.

- Industrial Machinery – Gears, shafts, camshafts, and bearing housings.

- Consumer Goods – Handles, knobs, decorative metalwork, and custom jewelry.

- Research & Development – Rapid prototyping for academic and corporate labs.

4. Quality and Accuracy

- Dimensional Accuracy – ±0.001 mm tolerance on all critical dimensions, verified by coordinate measuring machines (CMM).

- Surface Integrity – Controlled roughness (Ra < 1.6 µm) and minimal residual stresses.

- Material Homogeneity – Heat‑treated alloys and graded composites processed with thermal control.

- Consistency – Automated tooling changes, real‑time monitoring, and closed‑loop control.

5. Parameter Table

| Parameter | Minimum | Typical | Maximum |

|---|---|---|---|

| Tool Diameter | 0.6 mm | 10 mm | 200 mm |

| Spindle Speed | 500 rpm | 12,000 rpm | 30,000 rpm |

| Feed Rate | 0.05 mm/rev | 10 mm/sec | 200 mm/sec |

| Depth of Cut | 0.1 mm | 5 mm | 30 mm |

| Coolant Flow | 0.5 L/min | 5 L/min | 20 L/min |

| Workpiece Weight | 0.5 kg | 20 kg | 5 t |

6. Aluminum Vs Stainless Steel Material Properties Table

| Material | Density (g/cm³) | Modulus of Elasticity (GPa) | Yield Strength (MPa) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|

| 6061 Al | 2.70 | 68 | 276 | 167 |

| 7075 Al | 2.80 | 71 | 503 | 140 |

| 304 SS | 7.93 | 190 | 215 | 16 |

| 316 SS | 8.03 | 193 | 290 | 16 |

| Cu | 8.96 | 110 | 210 | 400 |

| Brass | 8.5 | 100 | 200 | 120 |

| Ti‑6Al‑4V | 4.43 | 115 | 880 | 7 |

| Inconel 718 | 8.2 | 210 | 1100 | 11 |

7. Machining Instructions (Step‑by‑Step)

- Design Finalization

- Upload 3D CAD files (STEP, IGES, STL).

- Perform tolerance analysis and clash detection.

- Tool Selection

- Choose carbide, high‑speed steel, or diamond tools based on material.

- Set tool life parameters and retraction strategies.

- Program Generation

- Create G‑code with adaptive feed, toolpath optimization.

- Simulate in virtual environment (CAM software).

- Setup & Alignment

- Mount part on CNC fixture, verify zero point.

- Calibrate spindle speed and tool offsets.

- Machining

- Execute roughing, semi‑finishing, and finishing passes.

- Apply coolant and monitor temperature.

- Inspection

- Measure critical dimensions with CMM.

- Verify surface roughness (profilometer).

- Post‑Processing

- Deburr, sand, or polish as required.

- Apply surface treatments (anodizing, plating).

- Final QA & Packaging

- Document all measurements.

- Package with protective labeling.

8. Custom Guide

| Stage | Customer Action | GreatLight Action |

|---|---|---|

| Initial Consultation | Provide brief, drawings, and required tolerances. | Offer technical advice, cost estimate, and timeline. |

| Design Review | Submit CAD files. | Conduct clash detection, recommend toolpaths. |

| Prototyping | Approve sample design. | Produce first machining run, deliver sample. |

| Approval | Inspect sample, request adjustments. | Implement changes, repeat if necessary. |

| Production | Sign production order. | Manufacture parts, perform QA, ship. |

| Post‑Delivery Support | Report any issues. | Provide warranty service and corrective actions. |

9. Price Advantage

- Competitive Base Rates – Lower than regional averages due to high automation.

- Volume Discounts – Tiered pricing for 100–10,000+ units.

- Transparent Billing – Itemized cost sheets, no hidden fees.

- Flexible Payment Terms – 30% deposit, 70% upon delivery or milestone.

10. Delivery Cycle & On‑Time Performance

| Order Size | Lead Time | On‑Time Delivery |

|---|---|---|

| 1–10 units | 24–72 h | 100 % |

| 10–100 units | 5–10 days | 98 % |

| 100–500 units | 10–20 days | 97 % |

| 500–1,000 units | 20–30 days | 95 % |

| >1,000 units | 30–45 days | 93 % |

- Real‑time tracking dashboard.

- Dedicated logistics partner for expedited shipping.

11. Communication Efficiency & Technical Support

- Multilingual Support – English, Chinese, Spanish, German.

- 24/7 Live Chat – Immediate response for urgent queries.

- Dedicated Account Manager – One point of contact for all projects.

- Technical Forums & Knowledge Base – Access to best practices, FAQs, and tutorials.

12. Technical Capabilities & Equipment

| Machine Type | Axis | Max Work Envelope | Tooling | Special Features |

|---|---|---|---|---|

| 5‑Axis CNC Milling | 5 | 4 m × 2 m × 2 m | 200+ tools | Adaptive spindle, high‑speed coolant |

| 4‑Axis CNC Milling | 4 | 2.5 m × 1.5 m × 1.2 m | 120+ tools | Dual‑spindle, RF‑cutting |

| 3‑Axis CNC Lathe | 3 | 3 m | 180+ tools | Threading, broaching, turning |

| 5‑Axis CNC Lathe | 5 | 2 m | 150+ tools | Complex surface machining, internal cavities |

- Software Suite – Siemens 840D, Fanuc iRV, Mastercam, SolidCAM.

- Tooling – High‑performance carbide inserts, ball‑nose, V‑bit, end mills, drill bits.

- Monitoring – Real‑time vibration, force, temperature sensors.

13. Quality Control System & Certification

- ISO 9001:2015 – Continuous improvement, risk‑based thinking.

- AS‑9100 – Aerospace‑specific processes (optional).

- ISO 14001 – Environmental management.

- OHSAS 18001 – Occupational health and safety.

- Regular Audits – Internal and third‑party inspections.

14. Confidentiality & Intellectual Property Protection

- Non‑Disclosure Agreements – Signed with all clients.

- Secure Data Handling – Encrypted file transfer, access control.

- IP Ownership – Clients retain full ownership of designs and specifications.

- Audit Trail – Log of file access, modifications, and transmissions.

15. Supply Chain Stability & Risk Management

- Multiple Raw Material Sources – Domestic and international suppliers.

- Inventory Buffer – Stock of critical metals and toolsets.

- Disaster Preparedness – Business continuity plan, redundant power supplies.

- Financial Stability – Credit lines, insurance coverage.

Why Choose GreatLight?

- Precision Engineering – Tolerances down to 0.001 mm ensure parts fit perfectly.

- Rapid Turnaround – Prototypes ready in a day, production in weeks.

- Versatility – From stiff aluminum brackets to delicate brass gears.

- Cost‑Effective – Competitive pricing without compromising quality.

- End‑to‑End Service – From design consultation to post‑processing and packaging.

- Transparent Processes – Real‑time tracking, open communication.

- Reliability – Proven on‑time delivery and robust quality controls.

- Innovation – Continuous investment in cutting‑edge CNC technology.

Contact GreatLight CNC Machining Center

- Phone (WhatsApp): +86 180 2756 7310

- Email: [email protected]

- Website: glcncmachining.com

Let us transform your design into a precision‑crafted reality. Reach out today for a free consultation and discover how GreatLight can accelerate your product development cycle while delivering unmatched quality.

Reviews

There are no reviews yet.