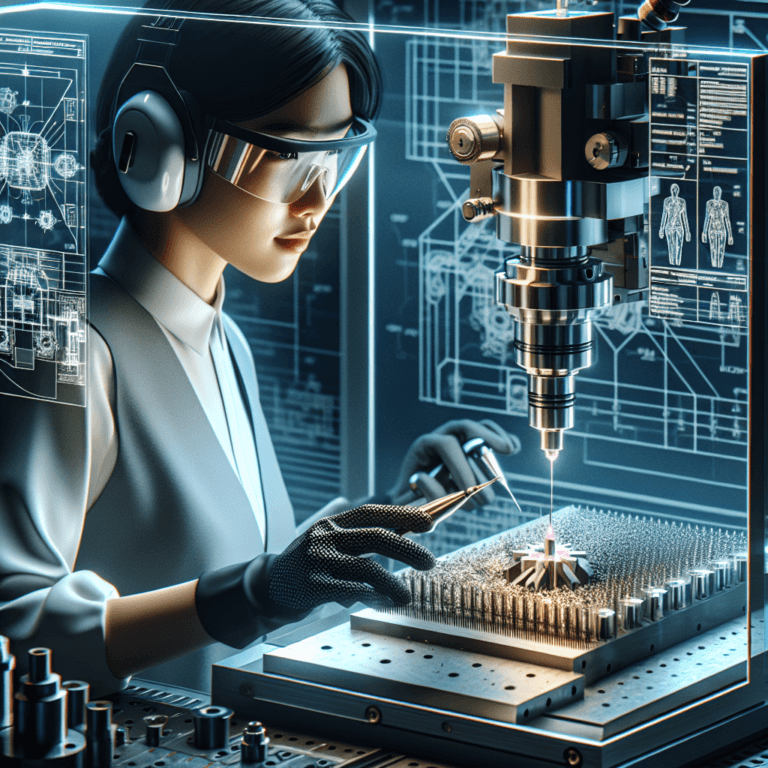

CNC (computer numerical control) machining has transformed manufacturing processes across industries, enabling unparalleled precision and efficiency. This article delves into the intricacies of CNC machining technology, exploring the diverse technologies that power this important component of modern manufacturing.

Understand the basics of CNC machining

CNC machining is a subtractive manufacturing process that uses a computer system to control machine tools. These tools include lathes, milling machines, milling machines and grinders. By converting digital designs into precise motion, CNC machining can consistently create complex parts and assemblies with high tolerances.

CNC machining workflow

design model: The first step involves creating a CAD (computer-aided design) model of the part. Designers use software such as SolidWorks or AutoCAD to develop detailed blueprints outlining dimensions, shapes, and other attributes.

Generate G code: After the CAD model is finalized, the next step is to convert the design into G-code, a programming language that controls CNC machine tools. CAM (Computer Aided Manufacturing) software is used to generate this code based on design parameters.

Set up the machine: Before machining begins, the operator sets up the CNC machine, installs the appropriate tools and loads material. Take precise measurements to ensure alignment and calibration.

Execution of the machining process: The CNC machine reads the G-code and starts the manufacturing process. It moves precisely along a predetermined path to remove material, producing the final part.

- Post-processing and inspection: Finally, manufactured parts typically undergo post-processing steps such as grinding, anodizing or polishing, and are inspected for accuracy and quality.

Types of CNC machining technology

CNC machining can be divided into a variety of technologies based on the type of material removal and machine configuration. Here are some of the most popular CNC machining technologies in use today:

1. CNC milling

CNC milling involves rotating a cutting tool on a fixed workpiece to remove material. The technology is versatile and can create complex shapes and features, suitable for a variety of industries.

Main features of CNC milling

- Tool type: Use different types of cutting tools such as end mills, ball mills and face mills to suit different applications.

- 3- and 5-axis milling: Standard milling machines typically operate in three axes (X, Y, Z), while advanced units can mill in five axes, allowing for complex designs and improved accuracy.

- Material compatibility: Can process a variety of materials, including metals, plastics, wood and composites.

2. CNC turning

CNC turning is a technique that uses fixed cutting tools to shape a rotating workpiece. This method is mainly used to produce cylindrical parts and is commonly used in the automotive and aerospace fields.

Main features of CNC turning

- lathe: These machines operate on CNC lathes and are designed to handle rotational motion, allowing for high-speed operation.

- accurate: Known for providing excellent surface finish and tight tolerances.

- efficiency: Able to quickly produce large quantities of parts, ideal for mass production.

3. CNC plasma cutting

CNC plasma cutting uses plasma as the cutting tool to cut conductive materials such as steel, aluminum and copper. The technology is favored for its speed and ability to cut thick materials.

Advantages of CNC plasma cutting

- speed: High efficiency, can process large pieces of material quickly.

- flexibility: Can be easily cut into various shapes and designs and adaptable to different material thicknesses.

- High cost performance: Ideal for manufacturers looking to reduce operating costs over time.

4. CNC laser cutting

CNC laser cutting utilizes a focused laser beam to melt, burn or vaporize materials, providing exceptional versatility and precision.

Key Attributes of CNC Laser Cutting

- accuracy: Laser cutting can achieve extremely tight tolerances, typically within ±0.001 inches.

- Material range: Effective on a variety of materials, including metal, plastic, wood and glass.

- Minimize waste: Produces less cuts (material loss), making it a sustainable choice for manufacturers.

5. CNC electrical discharge machining (EDM)

EDM processing involves using electrical discharges to erode materials, making it particularly suitable for hard metals and complex geometries.

Characteristics of CNC EDM

- fine details: Able to create complex designs that are difficult to achieve with traditional cutting methods.

- complex shapes: Ideal for prototyping and production molds due to the ability to create unique geometries.

- Contactless process: Minimize mechanical stress on parts and reduce the risk of deformation.

Choosing the right CNC machining technology

Choosing the right CNC machining technology depends on a variety of factors, including the material being machined, complexity of the design, required tolerances and throughput. Here are some basic factors to consider when choosing a CNC machining method:

1. Material properties

Different materials respond to processing in unique ways. For example, metal versus plastic requires different tools and speeds. Understanding these characteristics is critical to getting the best results.

2. Part geometry and complexity

The complexity of the design determines which machining method is best suited for the task. For example, complex contours may be better suited for CNC laser cutting or EDM, while simpler cylindrical shapes can be efficiently produced using CNC turning.

3. Tolerance requirements

Parts requiring tight tolerances should be machined using technology capable of achieving precise specifications. CNC milling and EDM generally meet such requirements more reliably than other methods.

4. Yield

Evaluating the number of parts that need to be produced may influence the choice of CNC technology. High-volume production often favors methods that can run quickly and at scale, such as CNC turning or plasma cutting.

5. Cost and budget constraints

The overall cost of machining, including setup, tooling, and material costs, should be carefully considered. Some methods may require a higher upfront investment but have a lower cost per part when scaled.

The future of CNC machining

As technology continues to develop, CNC machining is expected to make significant advances. Innovations such as artificial intelligence, machine learning and automation are shaping the future of CNC machining.

The convergence of artificial intelligence and automation

Incorporating artificial intelligence into CNC systems will enable machines to learn from previous operations and autonomously optimize their processes. This may reduce production time, enhance quality control, and lower labor costs.

Advanced materials and technologies

New materials, such as advanced composites and alloys, require innovative processing technologies to efficiently manipulate them. Research into additive manufacturing technologies such as 3D printing may also provide unique opportunities to integrate CNC processes.

sustainable development practices

As awareness of environmental issues grows, CNC machining technology is expected to prioritize sustainability. Innovations that minimize waste, conserve energy and utilize environmentally friendly materials will become fundamental aspects of processing practices.

Education and training enhancement

In order to keep pace with technological advancements, ongoing education and training are critical for engineers and operators. An increasing number of educational institutions are beginning to offer specialized courses focusing on CNC technology to train a new generation of skilled workers.

in conclusion

CNC machining is a fundamental pillar of modern manufacturing, delivering unparalleled precision, efficiency and versatility. Understanding different CNC machining technologies and their applications is critical for industries looking to leverage this technology to gain a competitive advantage. As advancements continue to shape the future of machining, embracing innovation, sustainability and efficiency are critical to operating successfully in an ever-changing environment.

FAQ section

1. What is CNC machining?

CNC machining is a manufacturing process that uses computer-controlled machinery to remove material from a workpiece to create precise parts and components based on digital designs.

2. What materials can be processed using CNC technology?

CNC machining can process a variety of materials, including metals, plastics, composites, and wood.

3. What is the difference between CNC milling and CNC turning?

CNC milling involves rotating cutting tools moving over a fixed workpiece and is ideal for creating complex shapes. CNC turning, on the other hand, involves rotating the workpiece using fixed cutting tools and is mainly used for cylindrical shapes.

4. What are the advantages of CNC laser cutting?

CNC laser cutting offers high precision, minimal waste, and the ability to cut a variety of materials, allowing for the efficient production of complex designs.

5. How do I choose the right CNC machining technology for my project?

When selecting a CNC machining technology, consider factors such as material properties, part geometry, tolerance requirements, throughput and budget constraints.

6. What role does artificial intelligence play in CNC machining?

Artificial intelligence can optimize machining processes by learning from previous operations, thereby increasing efficiency, quality control, and reducing production time.

7. What is the future of CNC machining?

Future advancements in CNC machining are expected to include further integration of artificial intelligence and automation, new processing techniques for advanced materials, and a focus on sustainable manufacturing practices.

By unleashing the precision provided by CNC machining technology, industries can achieve production excellence, paving the way for innovation and advancement in the manufacturing industry.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.