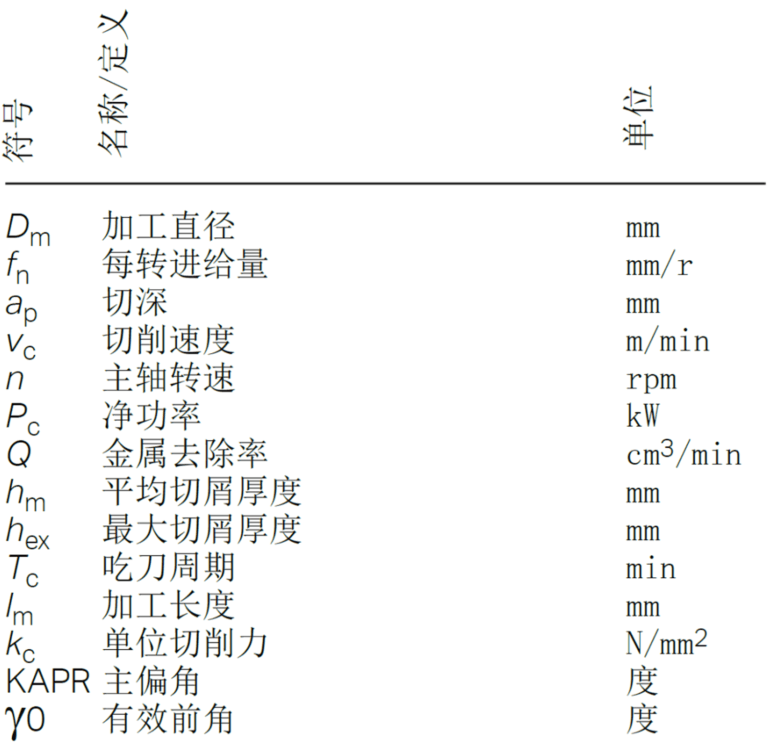

In the machining of turning, milling, drilling and boring machines, as a qualified technician, you must know the machining principles, cutting parameters and calculation formulas. Only with good basic knowledge can the processing performance of CNC machine tools and cutting tools be fully utilized. Many factory technicians use cutting parameters based on their feeling, and even think that these calculation formulas are useless. In fact, it’s not that the formulas are useless, it’s that we don’t understand them at all!

01 Definition and formula of filming

Turning is an application that uses single-edged tools to machine bodies of revolution and curved surfaces of revolution. In most cases, the tool is fixed in feed motion and the workpiece rotates as the primary motion.

02 Milling definitions and formulas

Milling is the process by which a multi-edged rotating cutting tool performs a programmed feed motion relative to a workpiece. Milling can be done in almost any direction.

03 Drilling definitions and formulas

Drilling covers making cylindrical holes in workpieces using metal cutting tools.

04 Boring definitions and formulas

Reaming is a process of machining holes using rotating tools. It is suitable for semi-finishing and finishing of pre-machined holes, cast holes, forged holes, extruded holes and gas cut holes.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.