Introduction: Compared to traditional manufacturing, one of the biggest advantages of 3D printing is customization. This feature has sparked a wave of innovation across many standard product industries, and the eyewear industry is one of them. The overall rate of myopia among Chinese children and adolescents ranks first in the world. It is especially important to choose a pair of glasses suitable for developing children to slow the growth of vision.

The data on everyone’s head and face is unique, and it is almost impossible to choose a pair of glasses that fits perfectly among standard products, but with 3D printing, all this is possible!

According to Mohou.com, Arkema joined hands with Jishu Medical to equip the eye health industry with their respective professional technologies, focusing on the research and development of the “3D personalized glasses” project, and jointly accelerating the cross-border integration and innovation. 3D printing technology and materials.

Jishu Medical is a medical company affiliated with Zhengxiang Group, focusing on innovative research and development including additive manufacturing and medical-industrial integration. Jishu Medical continues to actively explore the path of eye health, building new ideas for 3D printing to empower the eyewear industry, fully focusing on digital manufacturing and advanced production technology of eyewear. eyewear industry, by precisely presenting the “3D+glasses” product. and providing more eye health benefits. Providing patients with efficient, accurate and convenient 3D personalized glasses services.

Material properties determine product characteristics

In addition to meeting customization needs, a pair of high-quality 3D printed glasses also has characteristics of the product itself that are also particularly important, such as light weight, high flexibility and strong impact resistance. These benefits are directly determined. by the printing equipment. Rilsan® PA11 is a 100% bio-based, high-performance polyamide whose unique properties provide an excellent sustainable solution for 3D printing.

light

Wearing glasses for a long time will cause a feeling of pressure on the bridge of the nose, especially in adolescents and children whose bodies are still in the developing stage. Choosing lightweight materials will reduce discomfort. Rilsan® PA 11 has a low density, providing a lightweight wearing experience.

Resistant to shock and bending

Frequent bending of frames day after day will affect the lifespan of the glasses, so it is important to choose materials that are resistant to impact and bending.

An animated image tells you that only materials that can resist bending can make good glasses.

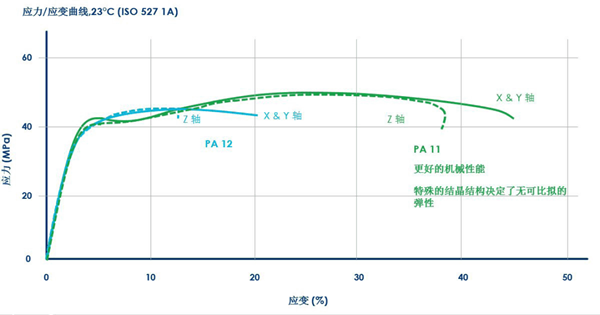

Rilsan® PA11 provides excellent tensile properties such as elongation at break, particularly in the direction of the Z axis, due to its more ductile crystal structure. (Z axis direction is generally the most vulnerable direction for additive processing)

Compared to PA12, PA11’s improved ductility allows designers to design thinner, lighter products while using less material. The flexibility and durability of the material helps extend the life of the product.

It is also worth mentioning that Rilsan® PA11 is a 100% bio-based polyamide derived from castor oil, renewable and recyclable, contributing to the development of a circular economy.

In the future, Arkema will continue to strengthen 3D printing, achieve deeper cross-industry integration, and help various industries achieve faster production, more personalized design and more sustainable product development through 3D printing. .

source:Arkema performance polymers

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.