Additive manufacturing (AM) The next phase of development will focus on the software part, such as organization and integration into production flows.3DPrinter control system, etc. These systems can also collaborate with pre- and post-processing robots to automate the entire printing process itself, reducing labor and costs. SO2023Year3DHow will software and automation evolve?

3DPrint simulation software

Wrought Director of Software Product Development Doug Kenikstates: “Better software, not hardware, will drive3DPrinting applications market.3D The simulation function in the printing workflow is to predict print success before printing, while eliminating risks from the printing process. Simulation is more widely used3Dkey for printing and manufacturing applications across a range of industries. “

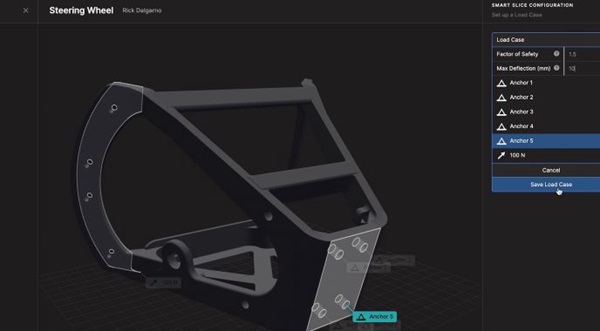

△2022 Year,Wrought Published Simulationwhich is a tool used to predict factors related to security and strength3DSoftware that prints the properties of carbon fiber parts can generate the loads, fiber quantities, etc. needed for different parts of the product. Photo by Wrought provide.

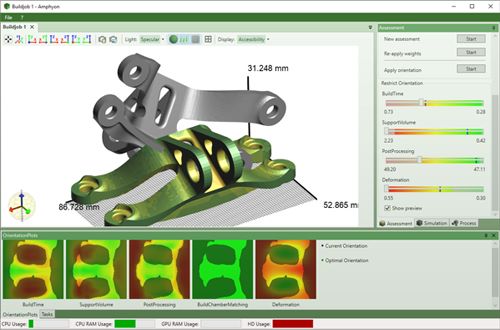

The simulation is AM An important development in software capable of predicting part performance and printing processes. Some developments have taken place in this area, including3D systems acquisition Additive works、Stratasys acquisition Torn,Torncan be predictedGUJATDeformation of the model to compensate for errors that occurred during the printing process.

△Additive works of 3D Print simulation. Photo by Additive works provide.

Software and automation go hand in hand

3D systems We also hired Brent Stark, one of the pioneers of additive manufacturing simulation. (Brent Stucker) The Dr is Chief Technology Officer. It will help guide the company on things like software, but since 3D systems software department Acton Operates independently, so it is difficult to determine how simulation scientists will be involved Acton global operations.Acton Senior Vice President and General Manager Ben Schrauwen The doctor emphasized that software will become an important part of automation.

with AM As it becomes more widely adopted as a production technology in the coming year, software will play an increasingly important role in three key areas: automation, traceability and verticalization.

Automation: With manufacturing industries such as service bureaus, healthcare, and consumer goods highly hybridized, the time and costs associated with preparing documents for the printing process are significant, and automation software Additive manufacturing will play a key role in facilitating automation. The use of modern artificial intelligence techniques such as deep learning can lead to very high levels of automation that were previously impossible. As efficiency increases and costs decrease, skilled employees can focus on other tasks that add value to the manufacturing environment.

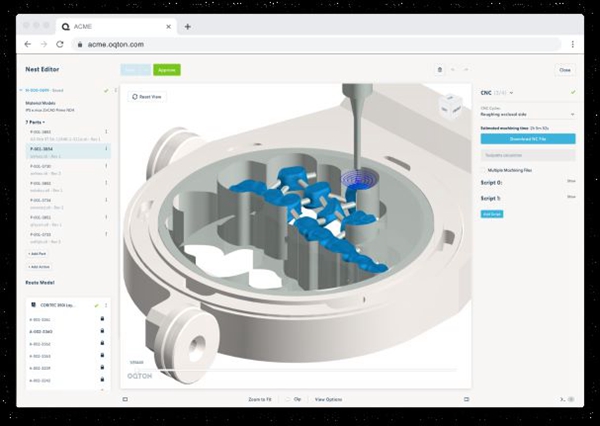

△Actonsoftware for dentistry3DPrint. Photo by Acton provide.

Traceability: For highly regulated industries such as medical and aerospace, it is believed that traceability of complete solutions (including maintenance, materials and operators) will continue to increase in importance, integrating multiple systems into one. The logging system becomes necessary.

●Verticalization: for expansionAMThe availability of soluble and easy-to-use vertical software solutions will continue to increase. Products include currently available dental application specific solutions, heat exchanger designs and compliant cooling mold inserts that do not require users to have extensive knowledge of the additive process, but can be the key to increasing the on a global scale, thereby stimulating the additives market.

StratasysVice President of Global Software Strategy Shaul SamaraHighlighting automation trends at both the hardware and software levels, he noted that the additive manufacturing industry has shown that the industry 3D Printers can meet the production needs of end-use parts, but more attention must now be paid to process automation. For example, currently60% arrive 75% work time is spent on tasks before starting to print.

●By automating steps such as quoting and reviewing jobs, pre-print labor time can be reduced to almost zero.

●In reality 3D During the printing process, material can be automatically replenished by sending it directly to the workstation, saving time, improving accuracy and significantly reducing waste.

●Finally, automated robots can be used to improve process repeatability and quality and obtain more parts with less labor.

These measures will enable the global manufacturing industry to truly begin to improve business processes at scale.

The automation engine

exist2023 In the annual forecasts,come to fruition CEO Fried vancraen Focus on automation trends.3DPrinting is a digital manufacturing technology, but it still requires a lot of manual intervention. And these skilled workers are increasingly difficult to find. Actually,Come to fruitionA recent survey showed that for those already using or considering 3D For printing companies, recruiting employees with the necessary expertise is the biggest challenge. At the same time, the industrial 3D Scaling print production to thousands or even millions requires a repeatable and consistent printing process. Both of these challenges increase the need for automation.

automation3DThe printing process includes different stages such as preparation, file repair and workflow automation.Materialization software General manager Bart Van der Schueren “In recent years, software has automated 3D Plays an essential role in all stages of the printing process, from file preparation and repair to post-processing. Now on an industrial scale 3D The future of printing requires repeatable and consistent printing processes in which not only the individual steps are automated, but also the processes between them. Come to fruition of CO-AM platform that allows manufacturers to automate not just individual steps, but the entire workflow, from order receipt to delivery and everything in between. “

AiBuild CEO of Many camerasWillAIconsidered as3DAn indispensable element in the development of printing. His company is building a solution optimized for machine learning 3D Printing technology development software. To drive the automation trend, he also expects “open architecture” to enable more synergies between hardware, materials and software.

Many camerasSay “to 2023 In 2020, we expect additive manufacturing to accelerate software and automation trends. First, new hardware will emerge due to end-customer demand for “open architecture” solutions./Material/Software partnerships. These systems will become more interconnected and become an integral part of the production chain. Second, artificial intelligence will transform additive manufacturing workflows. Manual trial-and-error approaches will be replaced by intelligent use of data and cloud-based machine learning solutions. With increasing levels of automation and seamless integration between hardware, software and materials, additive manufacturing technology will continue to expand into mainstream applications. “

3DPrint data security

Although data security has long been AM a topic of discussion in the field, but the technology has not quite reached production levels yet. This means that data security is either conceptual and managed on a project-by-project basis, or managed differently by each company. NOW3DPrint data security systems are reaching the level of high-volume production, and more industry-wide standardized solutions must be provided to protect data stored in the cloud, directly transferred and streamed.

Vancraen He said: “This new distributed digital production environment is built around one key asset: data. And this data must be protected to prevent the supplier from stealing the design and using it in their own domain.3DPrint on the printer. Of course, data security is important in any form of manufacturing, whether traditional or smart. But for 3D Printing is much more than that. Will3DTo increase the production of printed parts by the thousands or even millions, manufacturers must optimize and refine their printing processes so that they are efficient, reliable and repeatable across multiple production sites. Intelligent production processes ensure 3D Printed parts are of the same quality regardless of where they are produced. Creating such a process is complex and time-consuming, but it can improve a company’s competitiveness. This is why, in addition to data security, data integrity is becoming a major concern for companies adopting digital manufacturing. “

Automated reality

Additive manufacturing consulting company 3Degrees Founder and CEO of Mike Vasquez Explain that although significant progress has been made in the areas discussed, the road ahead will not be easy. Significant progress will be made as these solutions are implemented and scaled.

MY Promoter Authenticate André Wegner, founder and CEO (Andre Wegner)said that while the entire industry hopes 3D Printing software is better integrated with larger-scale manufacturing operations, but there will be a difference between looking for pre-packaged and custom solutions.

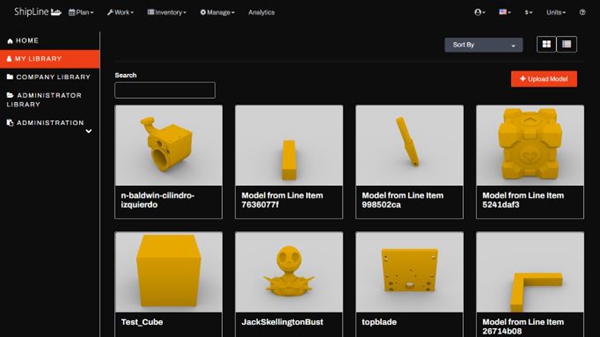

△Authenticate The Digital Design Warehouse is used to manage digital spare parts. Photo by Authenticate provide。

“As the market matures and larger players require more specific services, they increasingly use excel table and traditional ERP system. On the other hand, small service agencies are now well established and specific features (such as online quotes or production management) can be purchased off-the-shelf and are ideally suited. There will be a continued focus on integration because customers are tired of having to use multiple different tools. This will be driven by the growing acceptance of the cloud as a delivery system. “Wegner explain.

GPU supported MY software startup Dyndrite CEO of Harshil GoelHighlights the fact that software automation will transcendAMhimself. “Additive software automation will evolve to have a deeper connection to the manufacturing process, rather than the superficial state of database and business logic today,” he said. “This change will be linked to. CAM The software developments work together to provide convenient control and exploration of toolpaths to expand available materials, increase build speeds, improve part quality, and enable the printing of larger geometries. complex. Laser powder bed fusion users will experience these changes first, then the jet/Photopolymerization process. “

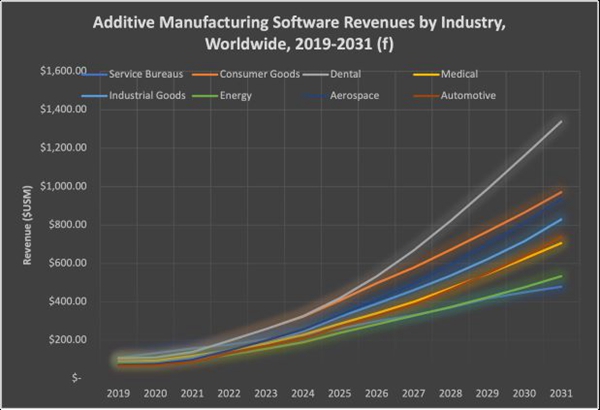

Regardless of the exact shape of the segments, we can confidently say that the additive manufacturing software and automation segment will grow rapidly. especially SmartTech Analysis In his ” 2023The report “Additive Manufacturing Software Market Opportunities in 2020” highlights that the software will start from the month of this year.12billion US dollars went to2031annual62billion dollars. (according toSmartTech Analysislatest reports, forecasts2031Year3DPrinting software market will reach62billion dollars.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.