One of the greatest challenges facing humanity today is undoubtedly climate change. Excess carbon dioxide in the atmosphere (CO2) causes the greenhouse effect, which warms the Earth. Although many scientists are working on the problem, the solution to global warming is unclear. However, rapid prototyping manufacturing technology could play a role in this, according to a new study from North Carolina State University. Researchers have demonstrated that the use3DIt is possible to create carbon dioxide capture filters using printing technology.

As mentioned earlier, the direct cause of global warming is industrial production, particularly the use of oil, which emits excess carbon dioxide into the atmosphere. In fact, according to the National Oceanic and Atmospheric Administration (NOAA) Annual report of the Global Monitoring Laboratory,2022The global average annual level of carbon dioxide in the atmosphere is parts per million417.06a new record, an increase from pre-industrial levels50%above. Not to mention that the absorption of carbon dioxide by the oceans leads to an increase in acidity.30%. But these problems are difficult to solve. Although ideally we would stop using the fossil fuels that cause this problem, many fear it will disrupt our way of life. So people are actively looking for ways to capture and store the carbon already in the atmosphere.

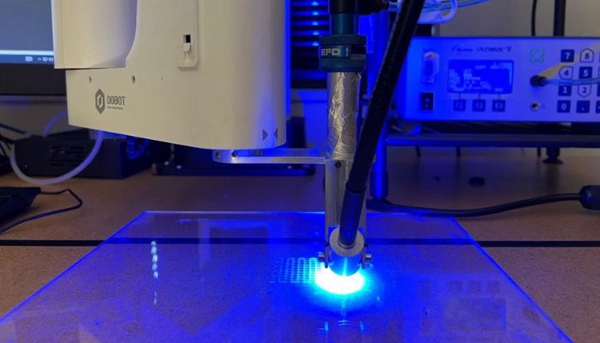

to use3DPrinting technology creates carbon dioxide capture filters(photo credits: Sen Zhang and Jialong Shen, NC State)

Recently, researchers at North Carolina State University demonstrated that using3DIt is possible to create carbon dioxide capture filters using printing technology. Concretely, through3DPrint a special hydrogel material capable of containing carbonic anhydrase. This is important because this enzyme speeds up the reaction that converts carbon dioxide and water into bicarbonate. Study first author, research assistant professor of textile engineering, chemistry and science at North Carolina State University.Jialong Shenexplain:“to use3DThe manufacturing process of printing technology makes everything faster and more precise. As long as you have a printer and raw materials, you can create such functional materials. Our formulated hydrogels have sufficient mechanical strength to function3DFor printing it can also be extruded into continuous filaments.

used for3DPrinted carbon dioxide capture filter

As mentioned previously, researchers3DPrinting technology as a faster, more versatile way to create carbon dioxide capture filters. Specifically, they used an extrusion process similar to material jetting.3DCrossing process between printing and photopolymerization. Specifically, it is composed of two different organic compounds and carbonic anhydrase.3DPrint “ink“. They were then able to print hydrogel filaments onto a two-dimensional mesh while curing the solution with UV light. Importantly, the resulting hydrogel can not only be extruded into continuous filaments, but is also strong enough to3DPrint.

Overall, they seem to be successful. According to a press release, in a small-scale experiment they were able to capture a mixture of gases containing24%of carbon dioxide. Although this ratio is lower than previous test results, this may be because the filter is less than an inch in diameter. Additionally, the filters can be enlarged and shaped into different shapes, stacked in a large column, to increase capture efficiency. Durability tests of this filter have also shown that more1000After hours, its carbon capture performance still remains at the initial level.52%。

Study co-corresponding author, associate professor of textile engineering, chemistry and science at North Carolina State UniversitySonja SalmonThe summary says:“This work is still in its early stages, but our results suggest new ways to create materials for carbon capture devices. We offer the hope of carbon capture.

source:3dnatives.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.