CNC (computer numerical control) machining has revolutionized manufacturing across industries, delivering precision, efficiency and scalability. As the demand for custom and high-quality machined parts continues to grow, choosing the right CNC machined parts supplier has become critical. In this article, we’ll take a deep dive into the top CNC machined parts suppliers you can trust, exploring their strengths, capabilities, and unique offerings. This extensive guide is designed to provide a comprehensive understanding of the CNC machining landscape while ensuring relevance to core industry keywords.

Learn about CNC machining

Introduction to CNC machining

CNC machining is a subtractive manufacturing process that involves the use of computer systems to control machine tools. These tools cut, shape and finish raw materials such as metals, plastics and composites with intricate precision. The development of CNC technology has given rise to various machining processes, including milling, turning and electrical discharge machining (EDM).

Benefits of CNC machining

precision and accuracy: CNC machines offer high levels of repeatability and precision, making them ideal for producing complex parts that adhere to tight tolerances.

Scalability: CNC machining supports both low- and high-volume production, allowing for expansion as demand fluctuates.

Material diversity: Can process a variety of materials, including metals such as aluminum, steel and titanium, as well as plastics and composites.

Shorten delivery time: CNC machining can significantly reduce lead times compared to traditional manufacturing methods, resulting in faster product delivery.

- automation: CNC equipment can operate continuously, thereby reducing labor costs and increasing output.

Criteria for selecting CNC machining parts suppliers

When looking for a trustworthy CNC machined parts supplier, you must evaluate them based on several key criteria:

quality control standards

Suppliers should adhere to strict quality control measures such as ISO 9001 certification. This ensures that the parts manufactured comply with international standards and customer specifications.

production capacity

Consider the supplier’s ability to handle a variety of processing techniques and materials. A versatile supplier will be able to meet a variety of project requirements.

Experience and expertise

Choose a supplier with extensive industry experience. Established suppliers typically have a proven record of reliability and innovation in CNC machining.

Customer support and communication

Effective communication is critical in manufacturing. Make sure the supplier you choose offers strong customer support to address your questions and concerns throughout the production process.

Reputation and Reviews

Look for vendors with positive customer reviews and recommendations. A reputation for reliability and high-quality output can indicate a supplier’s trustworthiness.

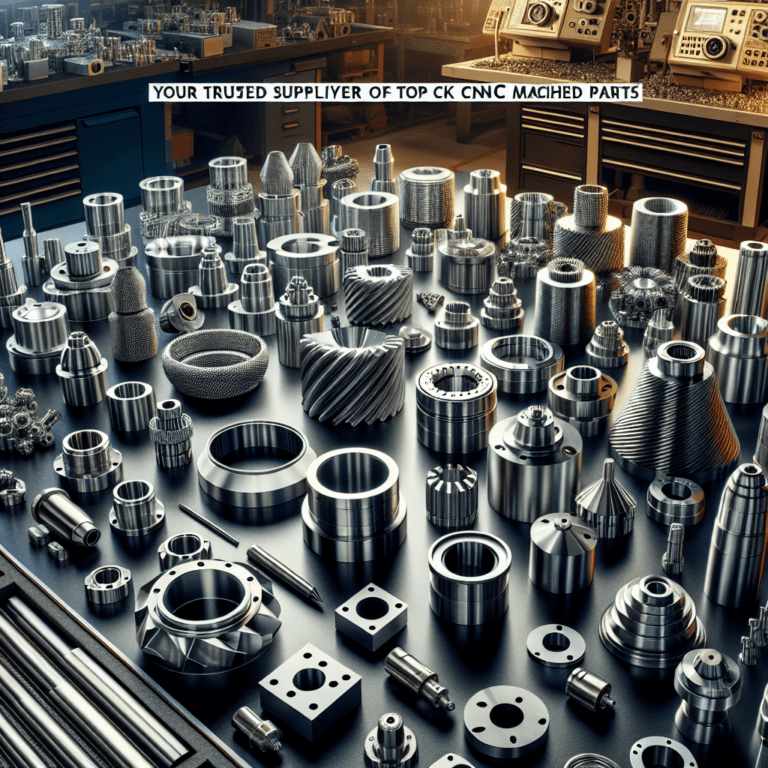

Your trusted supplier of top CNC machined parts

1. Haas Automation

Overview

Haas Automation is a leading manufacturer of CNC machine tools based in the United States. Known for its reliability and innovation, Haas has established a strong presence in the CNC machining industry.

Advantages

- Various CNC machine tools, including vertical and horizontal machining centers.

- A strong focus on research and development.

- Comprehensive customer support and training program.

Application areas

Haas machine tools are commonly used in the aerospace, automotive and medical industries to provide precision solutions for complex part requirements.

2.DMG Mori Seiki

Overview

DMG MORI is a global leader in CNC machine tools, specializing in high-precision machining solutions. The company has a rich history of innovation and collaboration, delivering cutting-edge technology.

Advantages

- Broad portfolio of CNC machine tools, including multi-tasking machines.

- A strong focus on sustainability and energy efficiency.

- Global reach and local support.

Application areas

DMG MORI machine tools are used in high-tech industries such as aerospace, military and medical equipment, where precision is crucial.

3. Processing solutions

Overview

Machining Solutions is a CNC machining services provider specializing in custom machining and prototype development. They offer a range of processing services tailored to individual customer needs.

Advantages

- Short turnaround time for prototypes and production runs.

- Has expertise in a variety of materials, including metals and advanced composites.

- Advanced machining technology, including 5-axis machining.

Application areas

Their custom solutions are suitable for industries such as automotive, electronics and consumer goods.

4. Prototype Lab

Overview

Protolabs is a leading digital manufacturing company specializing in rapid prototyping and on-demand production using CNC machining. Their innovative approach simplifies the manufacturing process.

Advantages

- Turnaround time is short, prototypes typically within 1-3 days.

- User-friendly online quoting and ordering system.

- Has expertise in a range of materials including engineering grade plastics and metals.

Application areas

Serving industries including medical, aerospace, and consumer electronics, Protolabs focuses on rapid development and innovation.

5.X measurement

Overview

Xometry is an on-demand manufacturing platform that connects businesses with quality CNC machining suppliers. Their model provides flexibility and scalability for a variety of project needs.

Advantages

- Access a vast network of vetted CNC suppliers.

- Instant quotes and fast delivery times via their online platform.

- Various manufacturing processes including CNC machining, injection molding and sheet metal fabrication.

Application areas

Xometry serves a variety of industries, including industrial equipment, automotive and electronics, facilitating rapid production and prototyping.

6. CNC machine shop

Overview

CNC Machine Shop is a service provider offering a full range of CNC machining services, including milling, turning and EDM. Their commitment to quality and customer satisfaction sets them apart in the market.

Advantages

- Focus on customer-driven solutions with custom design capabilities.

- Experienced engineers and mechanics ensure high-quality output.

- Competitive prices and transparent quotes.

Application areas

CNC Machine Shop serves customers in industries including aerospace, defense and consumer goods.

7. Fast and direct access

Overview

RapidDirect specializes in rapid prototyping and CNC machining services for product development. Their technology-driven approach improves manufacturing efficiency and precision.

Advantages

- Ability to handle complex geometries and tight tolerances.

- Available in a wide range of materials and finishes.

- High emphasis on quality assurance and testing.

Application areas

RapidDirect serves industries such as automotive, electronics and medical, facilitating rapid development cycles.

8. Precision Manufacturing Company (PMC)

Overview

PMC is a precision machining service provider that emphasizes quality and customized solutions. They focus on advanced technical capabilities to provide high quality machined parts.

Advantages

- State-of-the-art processing equipment and technology.

- Excellent reputation for on-time delivery and customer service.

- Specializing in high-precision machining.

Application areas

PMC primarily serves customers in the aerospace, defense and medical sectors, where precision is critical.

9. Hub

Overview

Hubs is an online manufacturing platform that provides access to a global network of CNC machining suppliers. They cater to different project sizes, from prototyping to low-volume production.

Advantages

- Quick online quoting and project management tool.

- A global network of vetted suppliers ensures high-quality output.

- Flexible manufacturing options including CNC machining, 3D printing and injection molding.

Application areas

Hubs serves a wide range of industries including automotive, electronics and consumer goods.

10. Turmac

Overview

Tormach is known for its affordable CNC milling machines designed for small and medium-sized businesses. They offer a unique approach to CNC machining with a focus on entrepreneurship.

Advantages

- Machines that make it easier for small business owners to enter the CNC market.

- User-friendly software and support resources.

- Focus on community and user engagement through forums and collaboration.

Application areas

Tormach primarily serves small businesses and educational institutions, promoting creativity and innovation in CNC machining.

in conclusion

Choosing a trustworthy CNC machined parts supplier is critical to ensuring the quality and accuracy of manufactured parts. Each of the vendors discussed in this article has unique strengths and capabilities that address the needs of a variety of industries. Whether you are looking for high-volume production, rapid prototyping, or precision machining, a thorough understanding of each supplier’s strengths and expertise will enable you to make informed decisions.

By combining your specific requirements with the expertise and products of these top CNC machined parts suppliers, you can create a successful partnership that improves your manufacturing efficiency and product quality.

FAQ section

Q1: What is CNC machining?

A1: CNC machining is a manufacturing process that uses computer-controlled machines to cut and shape materials into high-precision parts.

Q2: What materials can be used for CNC processing?

Answer 2: CNC machining can be applied to a variety of materials, including metals (e.g., aluminum, steel, titanium), plastics, and composites.

Q3: How to choose a suitable CNC machining supplier?

A3: Evaluate potential vendors based on criteria such as quality control standards, production capabilities, experience, customer support, and industry reputation.

Q4: What is the typical lead time for CNC machined parts?

A4: Delivery times vary by supplier and project complexity, but rapid prototyping services typically offer a 1-3 day turnaround time.

Q5: How to ensure the quality of CNC machined parts?

A5: Look for suppliers with ISO certification, robust quality control processes and positive customer reviews to ensure they maintain high standards.

By following this comprehensive guide and understanding the benefits of leading CNC machined parts suppliers, you’ll be empowered to choose the right partner for your manufacturing needs.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.