3DPrinting opens the door to innovation in the biomedical field. The main advantage of this technology is that it allows us to provide personalized solutions adapted to the needs of each patient. Thanks to this technology and3DCan the combination of printing and scanning play a unique role in orthopedics?

△Productto use3Dscan and3DCustom insoles printed and produced

2023Year1moon10According to Mohou.com, a company in the field of biomedicine and engineeringWypro 3D MedicalExclusive use3DTechnology designs and manufactures orthopedic insoles.

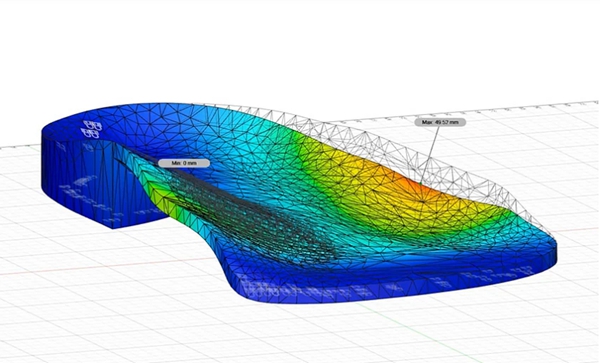

The company is based onRhinoceros 3D Modeland useGrasshopperDeveloped its own design software. One of the advancements it offers the industry is the variable plantar pressure density point system. The system applies specific densities in an automated manner based on the dynamic characteristics of each user’s fingerprint. In this way, they represent the possibility of obtaining a specific and personalized elastic response of the sole for each user, allowing specific solutions for sports or pathological applications, for example, to provide greater propulsion during specific phases of walking or for sports like boating. athletics provide greater dynamic range, etc.

△Productto use3DTechnology to make more advanced orthotic insoles that can provide biomechanical and other designs

3D designWhat are the advantages of digitalization?

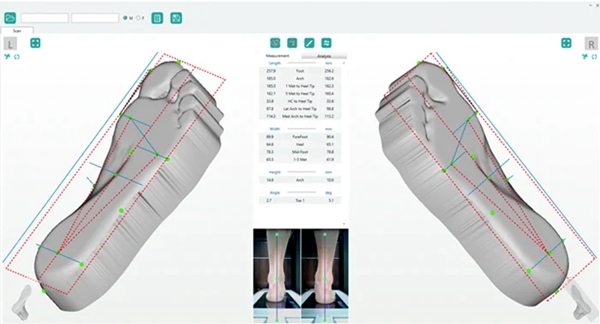

2017In 2007, the company developed products intended for podiatry and orthopedics.3Dlaser scannerWypro 3D scanning。ProductThe company explains that our industry often uses foam and plaster to measure foot size, but today these methods are clearly outdated. Now we can do it in less than1.5In a few seconds a file containing all the measurements and structures of the foot can be obtained, ending with35The 10,000 point grid form automatically connects to our cloud design platform and can upload files from anywhere in the world.

This technology has several advantages for professional users.Wypro 3D scanningCompared with traditional foot mold measurement technology, it has gravity sensing technology, which has the advantage of being closer to the actual return of the foot. The engineering team can then modify the scan as it is designed because many feet, such as flat and rigid feet, make it difficult to perform arch correction techniques due to the anatomy of the foot. collapsed foot. With traditional techniques, we would have had to spend hours correcting the forehead cast with varnish and eyes. This can be very inconvenient if the cast is lost or the patient needs an identical copy of the treatment years later. The company says that with its solution, it can now provide exact replicas to customers around the world.

△3D designfoot scanning technology

3DPrinted soles

After testing several3DAfter printing technology,ProductSelective laser sintering was finally chosen (SLS), in which they find the perfect balance between printing speed and precision. Able to provide customers100%Robust components to address problems such as mechanical stress on the foot (weight, deformation and fatigue).

With a low-power laser, the material is sintered and the parts obtained are very similar to those obtained by injection molding, with a very good surface finish. The company currently usesPA12As a primary material, it provides users with the flexibility and corrective properties necessary for insole comfort.

Productvision of the future

the company said3DPrinting is one of the most revolutionary advances in recent years. It successfully reduced the delivery time of the insoles and, combined with the custom software design of the foot orthotics, achieved micron-level control of the user’s feet. In recent years, due to new developments in open source printers and various materials, industrial grade printers3DPrinting has started to become more popular for startups, but it is difficult for them to invest large sums of money in advance in the purchase of such machines.

△Thanks to foot scanning, personalized insoles can be designed

at present,ProductWe are working with a multinational company to develop a product with mechanical properties between polypropylene andTPUresin enters. On the other hand, they are beginning to automate thanks to artificial intelligence, managing treatment predictions and the biomechanical design of insoles based on the diseases proposed by patients and the orders sent by professionals, seeking to reduce the design time and improve delivery times.

Source: Print Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.