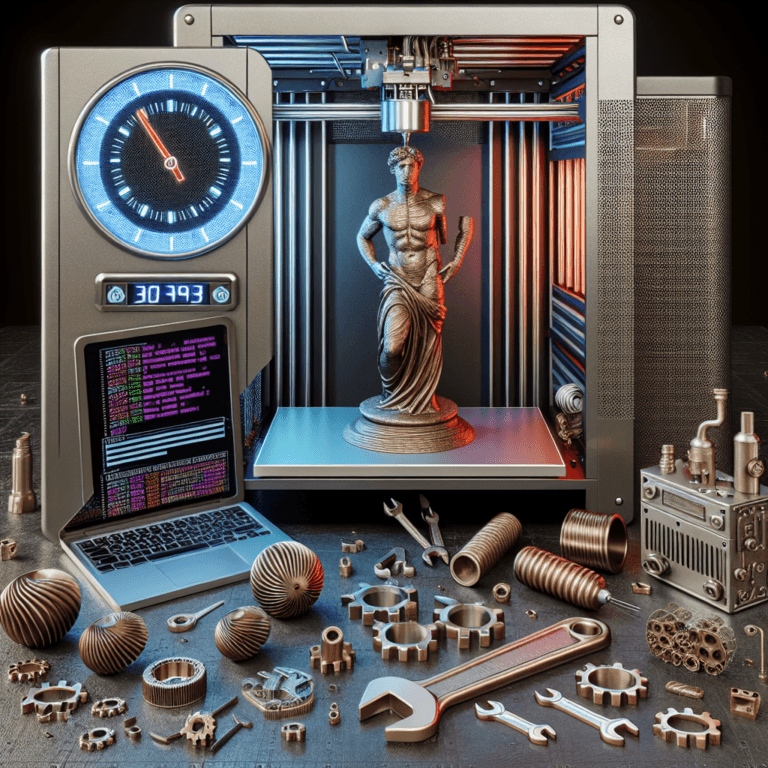

Metal 3D printing, also known as additive manufacturing, has transformed the manufacturing landscape, allowing for intricate designs and bespoke components that traditional manufacturing methods often can’t achieve. However, one prominent concern from users is the extended time frame needed to produce parts using this technology. In this article, we will explore why metal 3D printing takes so long, examining the various processes involved, the properties of the materials used, and the intricate designs commonly produced.

Understanding Metal 3D Printing Technology

To appreciate the time involved in metal 3D printing, it’s essential to understand how the technology works. Unlike traditional subtractive manufacturing, where material is cut away to create a part, 3D printing builds objects layer by layer. This layering process can vary based on the technology employed, such as Direct Metal Laser Sintering (DMLS), Electron Beam Melting (EBM), or Binder Jetting.

The general workflow includes design, preparation, printing, and post-processing, each of which contributes to the overall time required:

Design and Preparation

The first stage involves creating a 3D model of the part using computer-aided design (CAD) software. This phase can be surprisingly time-consuming, especially for parts that require intricate geometries or those that need to fit precisely within existing systems. The design stage also involves validating the design for printability, which means taking into account the material behavior during the build process, potential support structures, and the thermal dynamics of the material.Printing Process

The actual printing phase can take anywhere from hours to days, depending on several factors, including the size of the part, the complexity of the geometry, layer thickness settings, and the specific metal used. For example, larger parts or intricate designs will require more layers and more time to complete. Some technologies, like DMLS, focus on high precision but can take longer because they involve meticulous layer-by-layer melting of the metal powder.- Post-Processing

After printing, parts often require significant post-processing, which can dramatically affect the total time involved. This stage may involve techniques such as heat treatment to relieve internal stresses, surface finishing to improve aesthetics and functionality, or machining to achieve precise tolerances. These additional steps not only extend the lead time but also make the production process more complex.

Factors Influencing Printing Time

A multitude of factors influences the length of time required for metal 3D printing, including:

Material Properties

Different metals have varying thermal conductivities and melting points, affecting the speed at which they can be processed. For instance, titanium is known for its excellent strength-to-weight ratio but can be considerably more challenging and slower to work with than aluminum, which has a lower melting point and better fluidity.Build Size and Orientation

The size and the orientation of the parts on the build platform also significantly impact printing time. Larger components take longer to print, and the orientation can alter the printing path length. Effective orientation can minimize the use of support structures, reducing printing time and material waste.Layer Thickness

The choice of layer thickness is a critical factor in balancing print speed against surface finish and detail. Thicker layers can speed up the process, but they may result in a rougher surface finish, necessitating additional post-processing to achieve the desired specifications. Conversely, thinner layers yield finer details but significantly extend the printing duration.Printer Specifications

The capabilities of the 3D printer itself play a vital role in determining the print speed. Advanced machines capable of faster laser scanning and higher build rates can dramatically reduce printing times. However, these high-end printers often come with significantly higher costs, which may not be feasible for all businesses.- Support Structures

Complex geometries often necessitate the addition of support structures during printing to ensure stability. Designing and building these supports adds to the print time, and removing them during post-processing can further extend the overall timeline.

Implications of Long Lead Times

The long lead times associated with metal 3D printing do not simply present logistical challenges; they also have strategic implications for businesses:

Cost Considerations

Time is money. The longer a part takes to produce, the higher the cost of production, especially for businesses operating under tight budget constraints. Organizations must weigh the benefits of tailored components against the potential downtime caused by long lead times.Production Scheduling

In industries like aerospace, automotive, and medical devices, project timelines are often rigid. Prolonged production periods can affect overall project scheduling, leading to delays in delivery, increased costs, and potentially damaging client relationships.- Competitive Advantage

In a rapidly evolving market, speed to market can be a critical factor. Companies that can’t streamline their production processes may find themselves at a disadvantage compared to competitors who utilize more efficient manufacturing methods or technologies.

Advancements in Technology

Despite the challenges, new advancements in metal 3D printing technology are underway, promising to reduce production times significantly. For instance, emerging techniques such as high-speed DMLS are designed to enhance build rates without compromising part quality. Innovations in printing materials, including metal-polymer composites, can enhance properties and processing times, creating new opportunities for efficiency gains.

Moreover, improvements in software for integrating design, simulation, and production planning can also minimize lead times. Efficient workflows and automated post-processing solutions will streamline operations, yielding faster turnaround times.

Conclusion

While metal 3D printing offers unparalleled design flexibility and customization possibilities, the associated extended production times cannot be overlooked. Each element—from design to post-processing—plays a critical role in determining the overall lead time. As technology evolves, the industry is steadily working toward minimizing these timeframes through advanced materials, faster printing techniques, and improved workflows.

Understanding these factors can help businesses make informed decisions about incorporating metal 3D printing into their production strategies, ultimately balancing their needs for efficiency, cost, and quality. As the landscape of manufacturing continues to shift, staying ahead of the curve with these innovations will be paramount for companies focused on leveraging the full potential of metal 3D printing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.