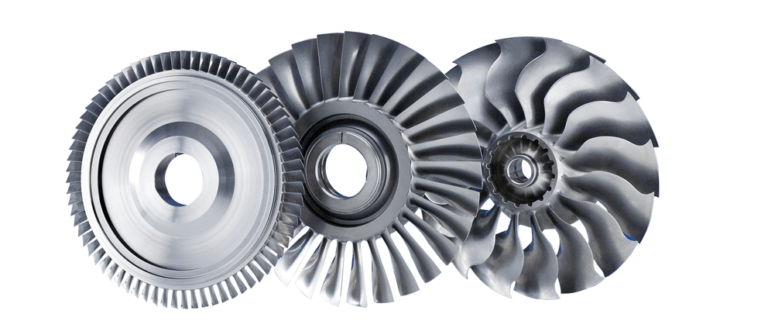

The aircraft engine is the “heart” of the aircraft and is also known as the “jewel in the industrial crown”. Its manufacturing integrates many advanced technologies in modern industry, involving materials, machining, thermodynamics and other fields. As various countries have increasingly higher requirements for engine performance, new structures, new technologies and new R&D and application processes are constantly challenging the pinnacle of modern industry. One of the elements that plays an important role in improving the thrust-to-weight ratio of aircraft engines is the blisk.

1

Advantages of integral bladed discs

Before the emergence of integrated hard drives, the motor rotor blades had to be connected to the wheel disk by tenons, tenon grooves and locking devices. However, this structure gradually proved incapable of meeting the needs of high-performance aeronautical engines. The bladed disk, which integrates the engine rotor blades and the wheel disk, was designed subsequently. It has now become an indispensable structure for high thrust-to-weight ratio engines and has been widely used in military and civil aviation engines. following advantages.

01. Lose weight

Since the wheel disc rim does not need to be machined with tongue and groove for blade mounting, the radial size of the rim can be significantly reduced, thereby significantly reducing rotor mass.

02. Reduce the number of parts

Besides the fact that the wheel disc and blades are integrated, the reduction of locking devices is also an important reason. Aircraft engines have extremely strict requirements for reliability, and the simplified rotor structure plays an important role in improving reliability.

03. Reduce air flow loss

It eliminates the exhaust loss caused by the gap in the traditional connection method, improves engine operating efficiency and increases thrust.

The integrated hard drive, which not only reduces weight but also increases thrust, helps improve the thrust-to-weight ratio, is not an easy “pearl” to choose. On the one hand, blisks mainly use difficult-to-machine materials such as titanium alloys and high-temperature alloys; on the other hand, their blades are thin and have complex blade shapes, which places extremely high demands on manufacturing technology. Additionally, when rotor blades are damaged, they cannot be replaced individually, which may result in the entire bladed disc being scrapped. Another problem is repair technology.

2

Manufacturing of bladed discs

Currently, there are three main technologies for manufacturing blisks.

01. Five-axis linkage CNC milling

Five-axis linkage CNC milling has been widely used in the field of blisk manufacturing due to its advantages of fast response, high reliability, good processing flexibility and short production preparation cycle. It mainly includes side milling, plunge milling and trochoidal milling and others. milling methods. Key factors to ensure successful blisk processing include:

1) Five-axis linkage machine tool with good dynamic characteristics

2) Optimized professional CAM software

3) Tools and application knowledge dedicated to processing titanium alloys/high temperature alloys

02. Electrochemical treatment

The electrochemical machining method is an excellent method for processing the entire bladed channel of aircraft engines. In electrochemical machining, there are mainly several processing technologies such as electrolytic nesting, profiling electrolytic machining and CNC electrolytic machining.

Since electrochemical machining mainly uses the characteristics of anodic dissolution of metal in the electrolyte, when electrochemical machining technology is applied, the cathode part will not be lost, and the workpiece during processing will not be affected by the cutting force, processing heat, etc. the stress after machining the entire bladed channel of the aircraft engine is reduced.

In addition, compared with five-axis milling, the working hours of electrochemical machining are greatly reduced, and it can be used in rough machining, semi-finishing and finishing stages. There is therefore no need for manual polishing after machining. is the ideal integral blisk for aircraft engines. One of the important development directions of channel processing.

03. Welding treatment

The blades are processed separately and, in a later step, welding technologies such as electron beam welding, linear friction welding or solid-state vacuum diffusion bonding are used to weld the pretreated blades to the blisk. Its advantage is that it can be used in the manufacture of bladed discs where the materials of the blades and discs are inconsistent.

When using the welding process, the blade welding quality should be high, which directly affects the performance and reliability of the entire bladed disk of the aero engine. Additionally, since the actual shapes of the blades used in welded bladed discs are not consistent and the positions of each blade after welding are not consistent due to limitations in welding accuracy, adaptive processing technology should be used to perform custom precision CNC milling of each blade.

In addition, welding is a very important technology in the repair of the entire blisk. Linear friction welding, as a solid phase welding technology, has high welding joint quality and good reproducibility. It is most suitable for high thrust welding. ratio of aircraft engine rotor components. One of the most reliable and reliable welding techniques.

3

Application of the integrated leaf disc

01. EJ200 aircraft engine

The EJ200 aero engine has a three-stage fan and a five-stage high-pressure compressor. A single blade is electron beam welded to the impeller disk to form an integral bladed disk, which is used in the third stage fan and first stage high pressure compressor. The bladed disk and the rotors of the other stages are not welded together to form an integral multi-stage rotor, but are connected using short bolts. Generally speaking, they are in the initial phase of applying bladed discs.

02. F414 turbofan engine

In the F414 turbofan engine, the second and third stages of the three-stage fan and the first three stages of the seven-stage high-pressure compressor use integrated bladed disks, which are processed by electrochemical methods. GE has also developed a set of feasible repair methods. On this basis, the integral blocks of the second and third stages of the fan are welded together to form an integral rotor, and the first and second stages of the compressor are also welded into one. , further reducing rotor weight and improving engine durability.

Compared with EJ200, F414 has taken a big step forward in the application of built-in hard disk.

03. Engine F119-PW-100

The 3-stage fan and 6-stage high-pressure compressor all use integrated bladed discs, and the first-stage fan blades are hollow. The hollow blades are welded to the wheel disk by linear friction welding to form an integral bladed disk, which reduces impact. weight of the rotor of this stage.

04. BR715 engine

In large civil engines, integrated bladed discs have also been used. The BR715 engine uses five-axis linkage CNC milling technology to process the integral bladed disc, which is used on the two-stage booster compressor after the fan, and the front and rear two-stage integrated bladed discs are welded together to form an integral rotor. It is used on the Boeing 717.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.