When processing parts, they must first be positioned and then clamped

Positioning refers to determining the position of the workpiece on the machine tool before processing. This process ensures processing accuracy by adjusting the correct relative positions of the tool and workpiece. The purpose of positioning is to ensure correct relative position between tool and workpiece to ensure processing accuracy and consistency.

Clamping refers to fixing the workpiece on the machine tool during processing to ensure smooth processing. This process is accomplished using tools such as montages. Fixtures can ensure that the workpiece does not move or vibrate during processing, thereby ensuring the quality and efficiency of processing.

Therefore, when processing parts, they must first be positioned to ensure that the relative position between the workpiece and the tool is correct, and then clamped to ensure the stability and precision of the processing process.

1. Basic principles of positioning from the side of the room

The basic principle of positioning from the side of the room is to follow the three-point principle. The three-point principle means that three points that are not on the same straight line determine a plane, so the part can be positioned at three points to ensure the positional accuracy and stability of the part.

When setting up the locator, three points should be used as a reference. The distance between these three points should be as large as possible to increase stability and positioning accuracy. In addition, the direction of the processing load, that is, the direction of movement of the tool holder/tool, should be confirmed in advance. Arranging a positioner at the end of the feed direction can directly affect the overall accuracy of the part. .

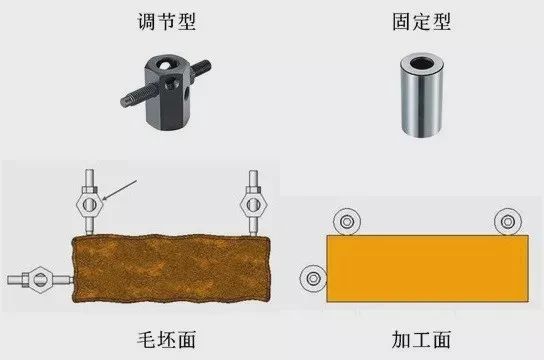

Generally, bolt-type adjustable positioners are used to position the rough surface of the workpiece, and when positioning the machined surface of the workpiece, a fixed positioner (the contact surface of the workpiece has been ground) is used. These positioners ensure that the part is held in the correct position for subsequent machining operations.

▲3-point principle

2. Basic principles of positioning from holes in the part

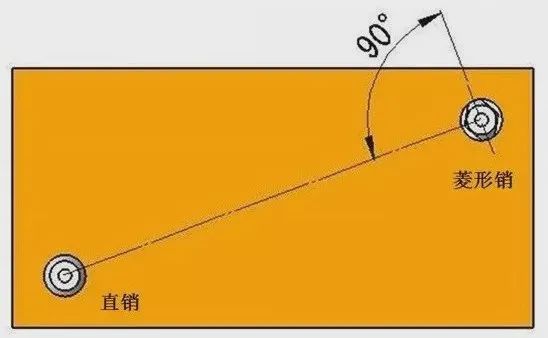

When positioning using the holes processed in the previous process of the part, pins with tolerances must be used for positioning. By matching the workpiece hole accuracy with the pin shape accuracy and combining them according to the fit tolerance, the positioning accuracy can meet actual needs.

When using pins for positioning, one usually uses a straight pin and the other uses a diamond pin. This makes it easier to assemble and disassemble the part, and it is rare for the part to get stuck with the pin.

For more precise positioning, it is generally more effective to use a straight pin and a diamond pin.

▲Use pin positioning

Knowledge related to pliers

1. Classification of pliers

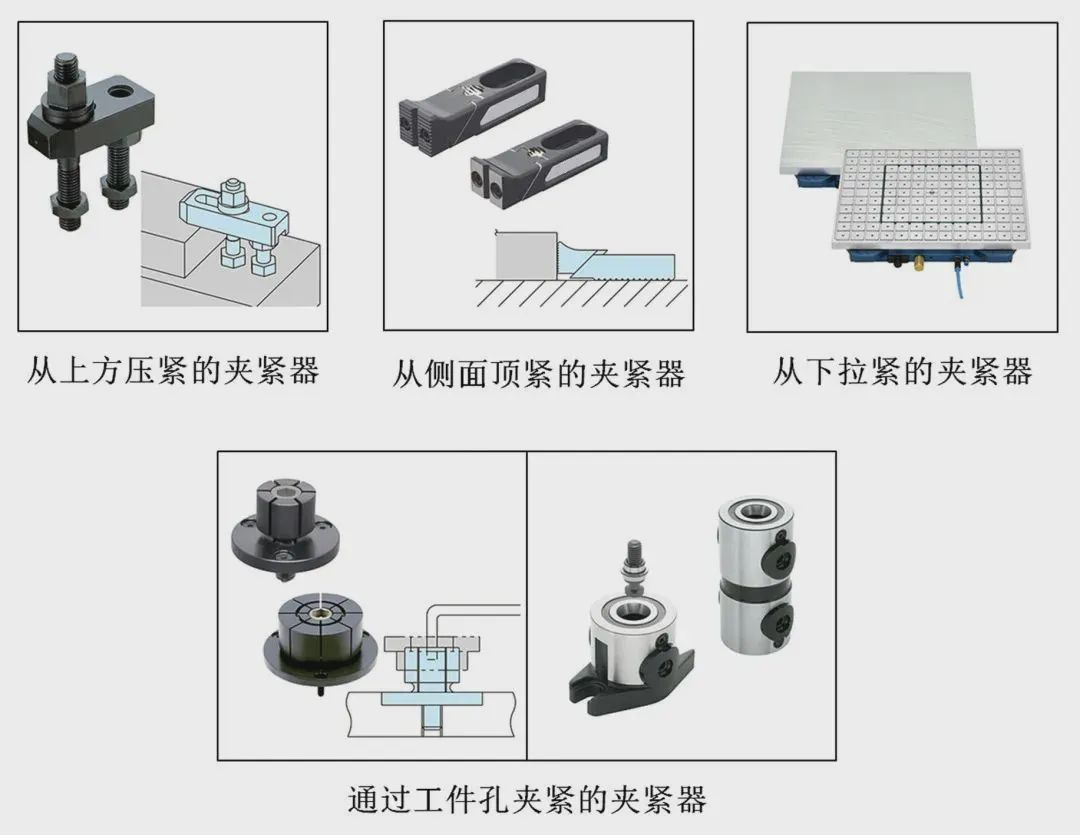

There are many ways to classify pliers. A common classification is based on tightening direction, which can be divided into the following categories:

Top-pressed clamp: This type of clamp has the least deformation when clamping and is the most stable during workpiece processing. Therefore, in general, the first consideration is to clamp the workpiece from the top. The most common clamp that is pressed above the workpiece is a manual mechanical clamp, such as the so-called “pine leaf” clamp in the image below. The clamp consisting of a pressure plate, a stud, a cylinder and a nut is called a “loose-leaf” clamp.

Side clamping: This type of clamp is mainly used when the top of the part must be processed, or when clamping the part from the top is not suitable. The side clamping device can effectively prevent the workpiece from floating.

Clamps that clamp the part from below: This type of clamp is mainly used for thin plate parts. When processing the upper surface, not only cannot it be clamped from the top, but it is also unreasonable to clamp it from the side. should only be tightened from below. The workpiece clamping method is the reasonable clamping method.

Clamps using hole clamping: When using a 5-axis processing machine for simultaneous multi-facet processing or mold processing, to avoid fixtures and tools affecting processing, it is generally more appropriate to use hole tightening. Compared with the method of top clamping and side clamping, the method of using hole clamping exerts less load on the workpiece and can effectively reduce the deformation of the workpiece.

Additionally, there are special types of pliers, such as pre-grips and pliers that use magnets or vacuum suction cups. When selecting a collet, factors such as the shape, size, weight and material of the workpiece, as well as the type and processing requirements of the processing machine tool, should be taken into account. taken into account to ensure that the correct clamp type and specifications are selected. .

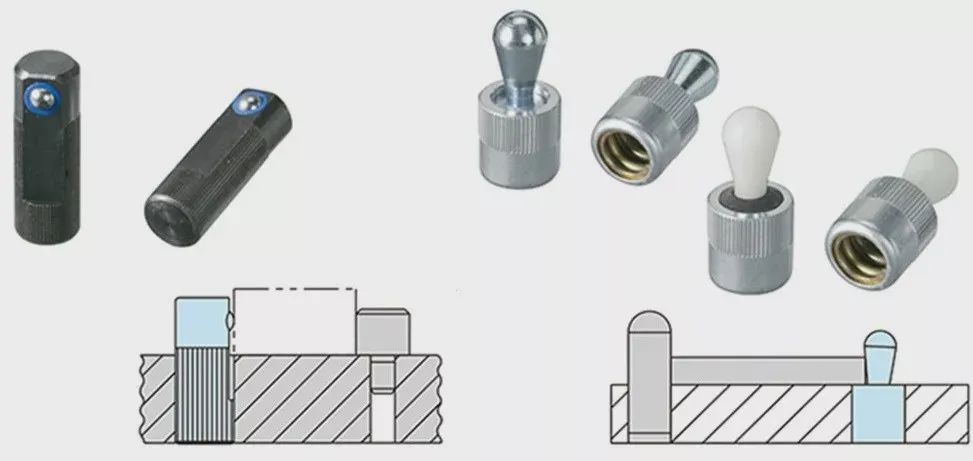

2. Pre-tightening

Pre-tightening is a tightening method that improves workpiece clamping operability and reduces setup time. When the piece is placed vertically, it will fall downward due to gravity. At this point you need to hold the workpiece while operating the clamp. The use of pre-clamping allows the workholding device to operate while the part remains stationary, significantly improving operability and reducing part clamping time. Especially when large weights or multiple parts are clamped at the same time, the operability will be greatly reduced and the clamping time will be very long. This problem can be solved by using this spring pre-tightening product.

▲Pre-tightening

3. Things to note when selecting a pliers include:

Consider part characteristics: Different part shapes, materials and processing requirements require the selection of different types of fasteners. For example, panel-shaped parts are suitable for flat clamps, and cylindrical parts are suitable for elastic clamps. At the same time, factors such as workpiece size, weight and precision requirements should also be considered to ensure that the device can fix the workpiece stably and meet the processing requirements.

Consider the machining load: The processing load refers to the forces and pressures the fixture is subjected to during machining. Depending on the importance of the processing load, the structure and materials of the luminaire will also vary. For intensive processing, it is necessary to choose fixtures with strong structures and wear-resistant materials to ensure the stability and safety of the processing process.

Consider the processing method: Processing methods include rough machining and finishing. Rough machining requires relatively few fixtures and it is usually possible to select a less expensive fixture. Finishing requires high precision and stability of fixtures, which is why precision fixtures must be selected to ensure processing quality.

Consider exchange time and work efficiency: The choice of lighting fixtures should also take into account exchange time and work efficiency. The process of replacing and adjusting fixtures should be simple and quick to improve production efficiency.

Consider safety: Operators should pay attention to safety when using the pliers. Before operation, check whether the fixture is fixed and whether the part is in the correct position to avoid accidents. During operation, attention should be paid to the movement trajectories of the device and the tool to avoid collisions between the device and the tool.

Consider regular maintenance: As a mechanical device, lighting fixtures require regular maintenance and maintenance to keep them in good working order. Maintenance includes cleaning the surface of the luminaire, lubricating the various friction parts and checking the tightness of each fixed part of the luminaire. Regular maintenance of devices can extend their lifespan while improving treatment stability and efficiency.

Consider rational use: Proper use of accessories is an important way to improve work efficiency. When selecting fixtures, the appropriate fixture should be selected based on the requirements of the processing task. When installing and adjusting the fixture, follow the instruction manual of the fixture and the machine tool to ensure coordination between the fixture and the machine tool. During the use of the luminaire, pay attention to the working status of the luminaire, then adjust and replace the luminaire in time to ensure the processing quality and work efficiency.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.