What type of parts is suitable for machining centers?Treatment centerIt is a highly automated multi-function machine-tool suitable for the treatment of the following types of parts:

1. complicated pieces

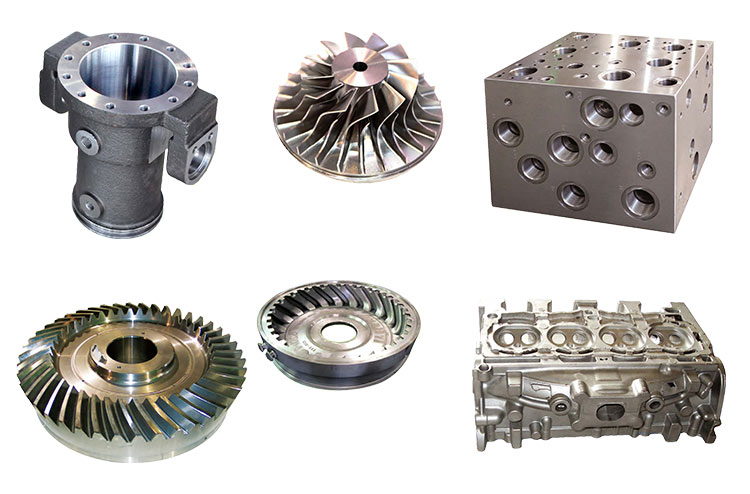

Boxes: like engine cylinder, transmission body, etc. This type of parts generally has holes, plans and various complex cavities in different directions. The holes are treated in a single tightening to ensure that this position and this dimensional precision between the parts.

Parts of mold: including injection mussels, dying mussels, etc. The cavity and the nucleus of the mold often have complex curved surface shapes.

Wheel parts: such as the engine wheel, the centrifugal compressor turbine, etc. The wheel blades are generally complex space surfaces and require extremely high machining precision and surface quality. The machining center can accurately form the curved surface of the blade by processing the multi-axis bond to ensure the aerodynamic performance of the wheel.

2. High precision parts

Aircraft parts: like the plane wingspath, landing gear, etc. These parts require extremely high precision requirements.

Documents of the precision instrument: such as the jamming of the coordinated measurement machine, a barrel of the objective of the optical instrument, etc. These parts require extremely high dimensional precision and surface quality.

3. Parts with complex hole systems and threads

Engine worship: The engine cylinder head requires the treatment of several valve holes, fuel injector holes, etc. Different diameters, depths and locations, and there are also a large number of threaded holes to install other components. The machining center can quickly and precisely complete the machining of various holes and threads thanks to a positioning of precise coordinates and automatic tool change functions, guaranteeing position accuracy between holes and quality systems of sons.

Binding box of the machine tool: there are different holes systems for mounting bearings, gears and other parts, as well as threaded holes for fixing and connection. The machining center can precisely process these holes systems and threads depending on the design requirements to guarantee the accuracy of the assembly and the overall performance of the pin box.

4. Parts produced en masse

Automobile parts: like the crankshaft, the car engine rod, etc. In automotive production, these parts must be produced en masse and the machining center can carry out the automated treatment by programming, improve production efficiency and stability of treatment quality and reduce production costs.

Case of electronic device: such as mobile telephony housing, computer housing, etc. These parts generally have certain precision requirements and require mass production. The machining center can quickly and effectively complete grinding, drilling and other shell treatment processes to ensure consistency and product quality.

5. Parts with special materials

Simed carbide parts: cemented carbide has the characteristics of high hardness and high wear resistance, and is difficult to treat. The machining center is equipped with appropriate tools and cutting parameters, which can precisely treat the cemented carbide to meet the dimensions and the precision requirements of the parts.

Titanium alloy parts: titanium alloy has excellent properties such as high resistance, low density, high temperature resistance, etc., but has poor machining properties. The machining center can effectively treat titanium alloy parts by optimizing the cutting process and the tool path, and is widely used in medical devices and other fields.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.