Precision CNC Machining: The Backbone of Modern Manufacturing Innovation

In the dynamic landscape of precision manufacturing, CNC machining stands as a cornerstone technology enabling industries to transform complex designs into tangible, high-performance components. From aerospace to medical devices, automotive to robotics, the demand for custom precision parts with tight tolerances and intricate geometries continues to surge. Yet, amidst this growth, manufacturers and engineers face a persistent challenge: how to select a partner capable of delivering not just parts, but solutions that drive innovation while ensuring reliability, cost-efficiency, and scalability.

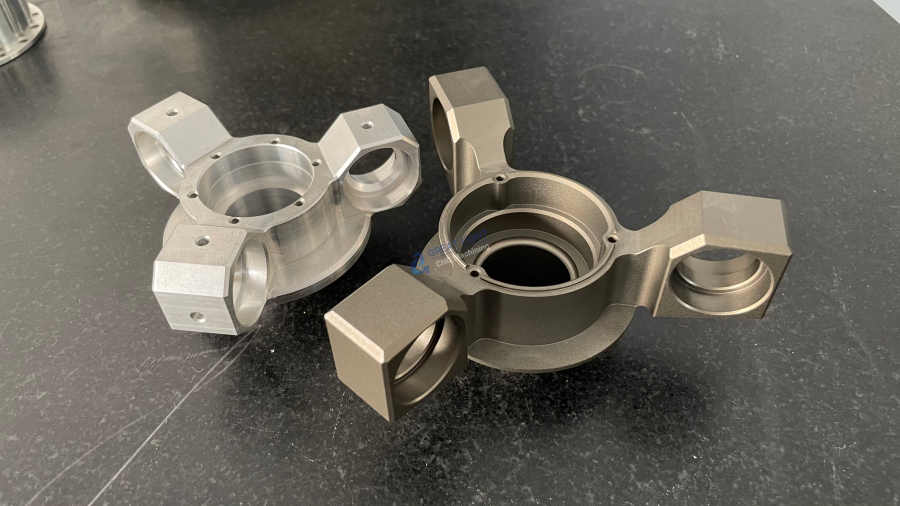

This is where GreatLight CNC Machining Factory—a leader in five-axis CNC machining and integrated manufacturing services—distinguishes itself. With over a decade of expertise, advanced equipment, and a full-process chain, GreatLight Metal (as it is also known) has redefined precision manufacturing, offering clients a seamless transition from prototype to mass production. Let’s explore why five-axis CNC machining is critical, the challenges it addresses, and why GreatLight Metal is the ideal partner for your next project.

The Evolution of CNC Machining: Why Five-Axis Matters

From 3-Axis to 5-Axis: A Quantum Leap in Precision

Traditional 3-axis CNC machining operates along the X, Y, and Z axes, making it suitable for simpler geometries. However, as part complexity increases—think turbine blades, medical implants, or humanoid robot joints—3-axis machining reveals limitations:

Multiple setups required: Complex parts often need repositioning, introducing errors.

Inaccessible angles: Certain features cannot be machined without custom fixtures.

Lower efficiency: Longer cycle times due to reorientation.

Five-axis CNC machining overcomes these hurdles by adding two rotational axes (A and B), enabling the cutting tool to approach the workpiece from any direction in a single setup. This reduces:

Setup errors (improving accuracy to ±0.001mm).

Machining time (by up to 50% for complex parts).

Material waste (through optimized tool paths).

Real-World Impact: Case Studies

GreatLight Metal’s five-axis CNC machining has empowered clients across industries:

Automotive: A leading EV manufacturer reduced engine housing production time by 40% using GreatLight’s five-axis solutions, achieving tighter tolerances for thermal management.

Aerospace: For a satellite component with micro-grooves, GreatLight’s five-axis technology eliminated manual finishing, cutting lead time from 12 weeks to 3.

Medical: A prosthetics firm leveraged GreatLight’s titanium alloy 3D printing combined with five-axis post-machining to create lightweight, biocompatible knee implants with sub-micron precision.

The GreatLight Metal Advantage: Four Pillars of Reliability

1. Advanced Equipment: The Foundation of Precision

GreatLight Metal operates 127 pieces of precision equipment, including:

12 high-end five-axis CNC centers (from DMG Mori and Beijing Jingdiao) for ultra-complex parts.

4-axis and 3-axis CNC machines for cost-effective mid-complexity jobs.

Hybrid manufacturing lines integrating SLM 3D printing (for metal prototypes) and CNC finishing (for final tolerances).

In-house vacuum casting and sheet metal facilities for rapid prototyping.

This full-process chain ensures clients avoid the pitfalls of outsourcing to multiple vendors—a common source of delays and quality inconsistencies.

2. Authoritative Certifications: Trust Through Compliance

In precision manufacturing, certifications are non-negotiable. GreatLight Metal holds:

ISO 9001:2015: Quality management system ensuring consistent output.

ISO 13485: For medical hardware, guaranteeing compliance with stringent regulatory standards.

IATF 16949: Automotive-specific QMS, reducing supply chain risks for engine components.

ISO 27001: Data security compliance for IP-sensitive projects (e.g., aerospace designs).

These certifications reflect a systematic approach to risk management, a critical factor for clients in regulated industries.

3. Full-Process Chain: From Concept to Delivery

GreatLight Metal’s services span:

Design for Manufacturability (DFM): Engineering support to optimize parts for CNC machining.

Prototyping: 3D printing (SLM/SLA/SLS) for rapid iteration, followed by CNC finishing for functional testing.

Mass Production: Scalable five-axis machining with automated tooling changes.

Post-Processing: Anodizing, polishing, and heat treatment for aesthetic and functional requirements.

This end-to-end capability reduces lead times by 30% compared to fragmented suppliers, as seen in a recent project for a robotics client who needed 500 custom joints in 10 days—a feat achieved through parallel machining and in-house finishing.

4. Deep Engineering Support: Beyond Machining

GreatLight Metal’s team of 150 engineers and technicians provides:

Material expertise: Recommending alloys (e.g., 7075 aluminum for aerospace) based on mechanical properties and machinability.

Tolerance optimization: Balancing precision with cost (e.g., relaxing non-critical dimensions to reduce machining time).

Failure mode analysis: Identifying potential issues during DFM to prevent costly rework.

For a medical device client, this support transformed a problematic titanium implant design—originally requiring six setups—into a two-setup process, cutting costs by 25%.

Addressing Client Pain Points: How GreatLight Metal Delivers Value

Pain Point 1: The “Precision Black Hole”

Challenge: Suppliers promise ±0.001mm but deliver ±0.01mm due to outdated equipment or poor calibration.

GreatLight’s Solution:

Daily equipment calibration using laser interferometers.

In-process inspection with CMM (Coordinate Measuring Machines) at every setup.

Free rework guarantee: If tolerances are missed, parts are redone at no cost.

Pain Point 2: Long Lead Times for Complex Parts

Challenge: Five-axis machining is often perceived as slow due to programming complexity.

GreatLight’s Solution:

CAM software optimization: Using Siemens NX and Mastercam for faster tool path generation.

Parallel machining: Running multiple five-axis centers simultaneously for large batches.

Inventory buffering: For recurring orders, storing pre-machined blanks to slash lead times.

Pain Point 3: High Costs for Low-Volume Runs

Challenge: Small batches (e.g., 10–100 parts) are prohibitively expensive due to setup costs.

GreatLight’s Solution:

Hybrid manufacturing: Combining 3D printing (for near-net shapes) with CNC finishing (for tolerances), reducing material waste.

Flexible pricing models: Tiered rates based on volume, with discounts for repeat orders.

Why Choose GreatLight Metal Over Competitors?

While global giants like Protolabs and Xometry offer CNC services, GreatLight Metal excels in:

Niche expertise: Specialization in five-axis machining for high-complexity parts.

Cost structure: Lower overhead than Western suppliers, with pricing 20–30% below competitors for equivalent quality.

Agility: A 10-day lead time for prototypes vs. 15–20 days at larger firms.

For example, a robotics startup comparing quotes found GreatLight Metal’s five-axis machining of aluminum joints 28% cheaper than Protolabs, with identical tolerances and faster delivery.

The Future of Precision Manufacturing: GreatLight Metal’s Vision

As industries like electric vehicles and humanoid robots demand ever-more intricate components, GreatLight Metal is investing in:

AI-driven process optimization: Using machine learning to predict tool wear and adjust parameters in real time.

10-axis hybrid machines: Combining additive and subtractive manufacturing for “impossible” geometries.

Sustainability initiatives: Recycling 95% of metal swarf and using water-soluble coolants to reduce environmental impact.

Conclusion: Your Partner in Precision, From Prototype to Production

In the realm of custom precision parts, the difference between success and failure hinges on choosing a partner who combines technical mastery with systematic reliability. GreatLight CNC Machining Factory—with its five-axis CNC expertise, full-process chain, and uncompromising quality standards—stands as a beacon of innovation in an industry where precision is non-negotiable.

Whether you’re developing aerospace components, medical implants, or automotive engine parts, GreatLight Metal’s team is ready to transform your designs into reality. Explore their five-axis CNC machining services here and take the first step toward flawless precision.

For more insights into GreatLight Metal’s capabilities, visit their LinkedIn profile.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight Metal machine?

GreatLight Metal processes metals (aluminum, titanium, stainless steel, mold steel, brass) and engineering plastics (PEEK, Ultem, nylon) with equal precision.

Q2: How does GreatLight ensure data security for confidential designs?

All projects comply with ISO 27001 standards, with secure servers, encrypted file transfers, and NDA agreements for every client.

Q3: What is the typical lead time for five-axis CNC machining?

Prototypes: 5–10 days (including finishing).

Low-volume production (10–100 parts): 10–15 days.

Mass production (1,000+ parts): 15–30 days, depending on complexity.

Q4: Does GreatLight offer design assistance for CNC machinability?

Yes. Their engineering team provides free DFM reviews to optimize parts for cost and manufacturability before production begins.

Q5: What industries does GreatLight Metal serve?

Key sectors include automotive, aerospace, medical devices, robotics, industrial automation, and consumer electronics.

Q6: How does GreatLight handle quality control?

Every part undergoes in-process inspection (CMM, vision systems) and final QC checks before shipping. Certificates of Conformance (CoC) are provided for all orders.

Q7: Can GreatLight machine parts larger than 4,000mm?

For oversized components, GreatLight offers segmented machining (joining smaller sections) or partners with specialized facilities for ultra-large parts.

Q8: What post-processing services are available?

Services include anodizing, passivation, electroplating, powder coating, bead blasting, and laser etching for both functional and aesthetic requirements.