2023Year7moon4day,According to Mohou.com,industry3DGlobal leader in printing solutionsVoxeljet AGHAS 2023 Year 6 famous moonGIFA2023A breakthrough innovation was presented at the show: a new coldIOB(Inorganic combination)3DPrinting technology. Using this unique process, molds and cores for the foundry industry can be produced from sand containing an inorganic binder without the need for microwave processing.

VoxeljetThis year, the company is GIFARelevant achievements in the field of inorganic materials were exhibited at the conference, including this new patent-pending inorganic cold hardening process technology (inorganic cold hardening process technology). IOB). In addition to presenting new processes at the exhibition,voxeljet It also shows how it works with Loramendi Printing at the heart of the BMW collaboration (PEAK) Results of industrialization projects.PCI The project involves a project in Landshut BMW A fully automated manufacturing cell operating in a light metal foundry. In this manufacturing cell, the cast core is printed with an inorganic binder and then hardened by microwave. It is therefore a thermal inorganicIOB。

△coldIOBTechnical process layout

coldIOB 3DPrinting technology: low investment and operating costs, low emissions

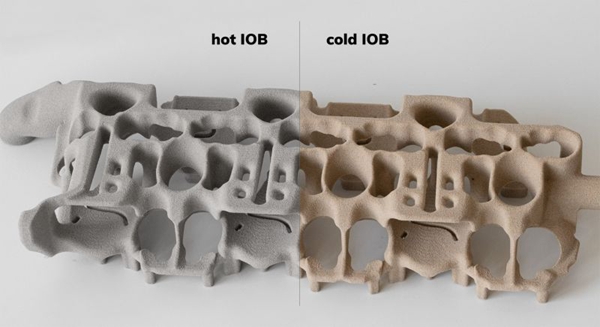

Sustainable production processes are more important today than ever. It isVoxeljetdevelopedIOB(Inorganic combination)3DWhat is printing technology? at present,VoxeljetTwo inorganic binder jet printing processes are available: cold for prototypingIOBand heat for additive mass productionIOBtechnology. with heat requiring organic bindersIOBTechnology compared to coldIOBTechnology has more advantages. This starts with environmental compatibility, because inorganic substances enable odorless and emission-free casting, which also benefits occupational health.

△coldIOBAnd hotIOBComparison of technologies

new coldIOBThe technology does not require microwave curing and therefore has lower capital and operating costs.IOB The use of technology brings many benefits to the foundry industry, such as the fact that only water vapor is produced during the casting process instead of harmful gases. This not only reduces exhaust emissions, but also improves working conditions in the foundry.

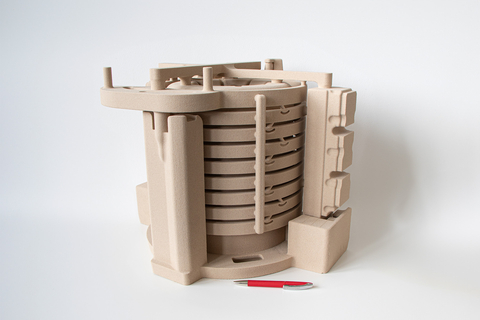

△Water Jacket-Core,Depend on voxeljet Use cold IOB Printing, for electric vehicle motor casings, in GIFA exposed

VoxeljetCEO Ingo Ederer The doctor said: “Cold IOB The introduction of the technology is an important step in promoting the foundry industry to accelerate the application of inorganic adhesives to printing cores and molds. Our goal is to provide innovative solutions that not only increase efficiency, but also help promote sustainability in metal casting. “

coldIOBThe characteristics of the processing technology and the molds and cores produced therewith include high dimensional accuracy, very good detail resolution and very good edge sharpness, and3DThe ability to print large molds and cores. Unlike heat which requires the use of a microwave to harden and dry the print core. IOB The process is different,Voxeljet cold IOB The technology only requires drying outside the machine after printing. Thus, customers can avoid the high investment and operating costs of industrial microwave ovens. This process can in principle be used in allVoxeljetused on the platform. Currently working on VX1000 And VX1000S This function is tested and available on the printer. There are plans to expand the product to include VX2000。

Voxeljet the strategy satisfies the cold IOB growing demand

The use of inorganic binders is becoming increasingly popular in the foundry industry, particularly in the automotive industry. Given increasingly stringent environmental regulations, the demand for inorganic binder molds and cores is expected to continue to grow.VoxeljetCommitted to expanding its role in environmental protection3Dleading position in the field of printing processes and thanks to this strategic positioningVoxeljetContribute significantly to the group’s sales growth.

cold IOB The technology is particularly suitable for prototyping and medium series and is now commercially available. Interested customers can already order benchmarks.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.