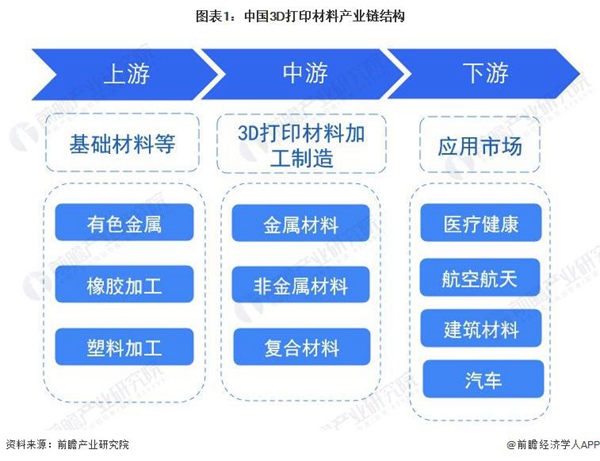

The upstream of China’s 3D printing materials industry mainly consists of mining, smelting and processing enterprises of basic materials, including non-ferrous metal smelting, rubber processing, processing plastic, etc., the middle sector consists of 3D printing material processing and manufacturing enterprises, which are divided; into three categories: metallic materials, non-metallic materials and composite materials. Downstream applications include medical health, aerospace, building materials, automotive and other fields.

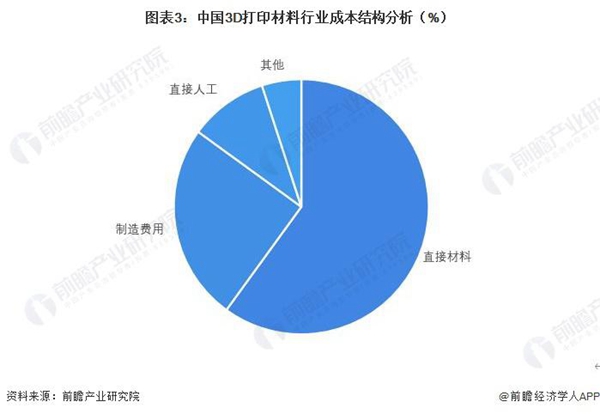

Raw materials are essential costs

As a representative company of metal 3D printing materials, Yue’an New Materials accounts for about 70% of its direct material costs. The direct materials in the main operating costs of Yue’an New Materials are mainly primary atomized alloy powder, sponge iron and liquid. Ammonia, coke, etc., since the primary atomized alloy powder has completed the initial manufacturing process, the cost is relatively high.

Combined with the cost structure of representative companies that 3D print metallic and non-metallic materials, the proportion of direct materials varies depending on the company’s initial processing needs for the material business, ranging from 50% to 70% ; The second largest cost, representing approximately 25% of direct labor, varies depending on the complexity of production, ranging from 5% to 15%;

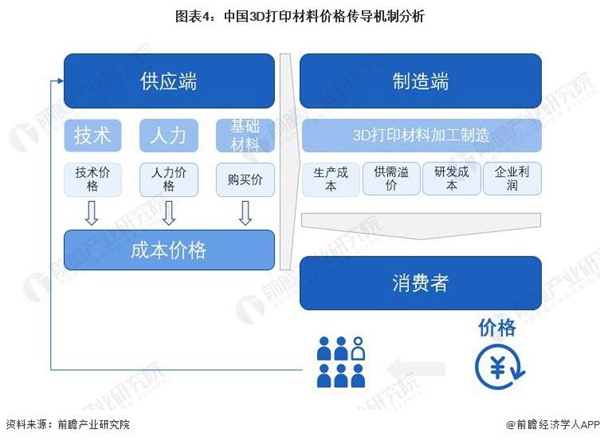

There is a certain premium as part of the price transmission mechanism

The market price of 3D printing materials in China is determined by the value-added premium on the supply side of the industry, the manufacturing side and the elasticity of consumer demand, and is transmitted step by step. The supply side cost price includes basic material prices, technology prices and labor prices, etc., which are passed to the manufacturing side and become production costs. The manufacturing side combines supply and demand premiums, R&D costs and corporate profits to form “manufacturing side prices” and is passed on to consumers, while demand elasticity The consumer market also reacts from the supply side and the manufacturing side, forming a “price-demand-price” transmission path to affect the market prices of 3D printing materials.

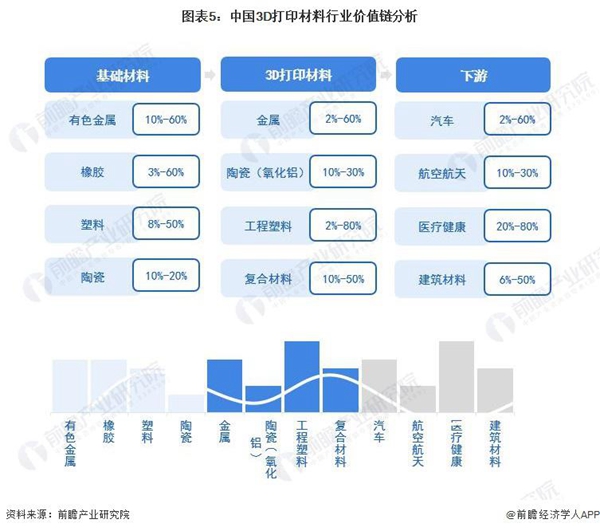

The value chain is a “smile curve”

According to the gross profit margin of each link in the 3D printing materials industrial chain, it is found that the gross profit margin of the upstream fluctuates greatly, mainly between 10% and 60%, which varies depending on the importance of each base material; the gross profit margin of 3D printing ceramic materials The level of interest rates is relatively low, between 10% and 30%; the gross margin level in the field of downstream medical and healthcare applications is the highest.

source:Qianzhan Industrial Research Institute

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.