From January to March 2023, China Aerospace continued to conduct vertical recovery demonstration and verification flight tests in Haiyang, Shandong, and successively carried out land launches, recoveries and sea recoveries. According to Mohou.com, in this test, 3D printing technology began to play a role. an important role.

The flight test simulates and verifies the flight process of land launch and sea recovery. It mainly verifies the sea landing process during the rocket substage return to orbit, communication and relative extent under the influence of marine clutter environment, as well as the process of flight. final stage of recovery and landing. The landing accuracy is evaluated in the kilometer-level flight environment and in the shaking of the sea landing platform. The maximum flight altitude is more than 1,000 m. After reaching the highest point, it adjusts its attitude and descends after hovering. The descent stage is decelerated by engine thrust reversal, so that the aircraft speed can be reduced to less than 1,000 m. 2 m/s when approaching the sea landing platform, then through the buffer stabilizers. Achieve a smooth landing, the whole flight takes about 10 minutes, and the landing point accuracy is better than 10m.

In terms of high-precision vertical return guidance and control technology, we have completed high-precision reentry navigation and positioning technology, vertical recovery online trajectory generation guidance technology powered by a prototype of carrier principle, adaptive flight control technology for complex environments and initial alignment. of the offshore tilting platform. And the verification work of long-term tracking technology and semi-physical verification technology of the entire flight.

The prototype of the vertical recovery principle of the sea launcher is used as a technical verification platform. At the beginning of the design, the innovative design concept was respected and the design of the integrated power and distribution-control-telemetry control system. and 3D printing were used to design and process the anti-sway storage tank, using a lightweight carbon fiber structure to achieve an integrated configuration of lift, force transmission and vibration suppression, which can integrate and reuse functions from multiple systems. , greatly simplifying the overall mass and cable connections, and can be realized in a similar small aircraft application.

The successful prototype demonstration test of the vertical recovery principle of China’s space launch vehicle at sea has verified a number of key technologies. The successful flight test will provide technical research and accumulation for the near-space recyclable scientific experiment platform, orbiting rocket substage recovery and space tourism aircraft, which will be applied in later models and orbiting rockets. sub-stage recovery missions.

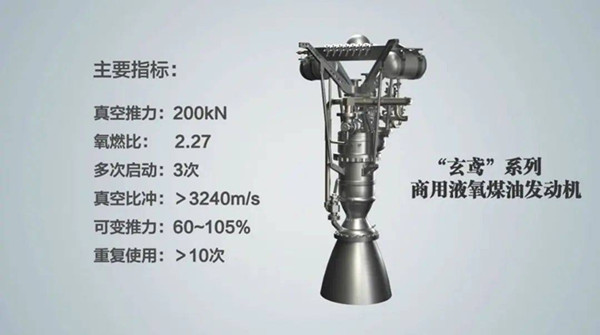

It is reported that the 20-ton liquid oxygen kerosene rocket engine “Xuan Yuan 1” to be tested by China Aerospace in 2022 widely uses 3D printing. The “Xuan Yuan 1” rocket engine is a liquid oxygen kerosene engine and cycle method. is a gas generator cycle, the starting method is gas cylinder starting, and the ignition method is TEA/TEB liquid ignition, which is mature and reliable.

This type of engine uses high pressure gas start and lighter agent ignition, easy to operate and simple to maintain; the thrust chamber pierces efficient and stable liquid-liquid combustion technology by adopting integrated design scheme of separation nozzles; The frame which is connected to the rocket body adopts mortise and tenon joints. The all-machine structure solution solves the difficulties of large deformation of the all-welded structure, complex processing tooling and long production cycle of a large number of key components such as turbine; pumps, thrust chambers and gas cylinders use comprehensive 3D printing technology, which greatly improves production efficiency; The whole machine structure adopts a modular overall layout, which greatly improves the production organization and assembly efficiency. Through the introduction of a large number of new technologies and processes, and on the basis of independent innovation, we have gradually explored the development and organization model of design, production and testing of low-cost and highly reliable commercial liquid rocket engines, providing a solid basis for the rapid realization of commercial launches in the future.

The “Xuanyuan-1” liquid rocket engine uses non-toxic and non-polluting oxygen/kerosene liquid propellant, adopts a gas-generating cycle scheme, and has the ability to start multiple times and change the operating conditions within a wide range. . Through the intensive application of mature industrial materials, standard parts and 3D printing technology, production costs are reduced and production cycles are shortened. The engine is used as the main power for the first stage of small launch vehicles, the second/third stage of medium-sized launch vehicles and suborbital vehicles, and can meet the recovery needs of the first stage of liquid rockets.

Source: China Aerospace

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.