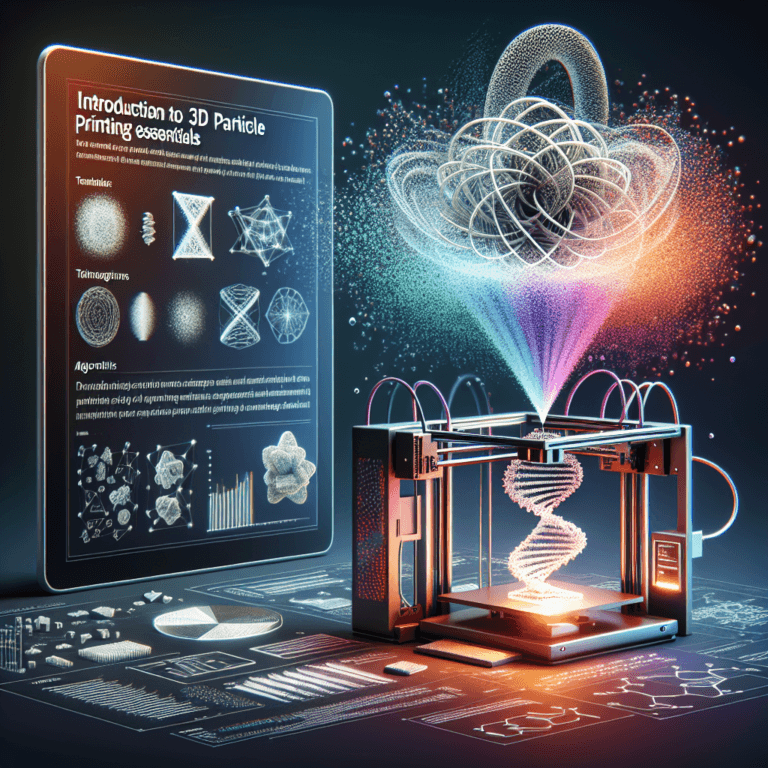

Understanding the Basics of 3D Particle Printing

What is 3D Particle Printing?

3D particle printing is an innovative manufacturing technique that combines the principles of 3D printing with the unique capabilities of particle-based materials. Unlike traditional additive manufacturing methods that use filaments or resins, 3D particle printing utilizes powders—small granules of material—to create three-dimensional objects through a layer-by-layer process. This technology has gained traction in various industries, including aerospace, automotive, healthcare, and consumer goods, due to its versatility and ability to produce complex geometries.

How Does 3D Particle Printing Work?

At its core, 3D particle printing involves several key steps:

Designing the Model: The process begins with the creation of a digital model using computer-aided design (CAD) software. The design must be optimized for additive manufacturing, meaning it should consider factors like support structures and material distribution.

Preparing the Machine: Once the model is designed, it’s converted into a format that the 3D printer can understand, typically a .STL or .OBJ file. The printer’s build platform is prepared by adding an initial layer of powder.

Layer-by-Layer Production: The printer deposits a thin layer of powder, followed by a binding agent or sintering process to fuse the particles together. This is repeated in successive layers until the entire object is formed.

- Post-Processing: After printing, the object typically undergoes post-processing steps, which can include curing, cleaning, or additional machining to achieve the desired finish and properties.

Key Advantages of 3D Particle Printing

3D particle printing offers several advantages over traditional manufacturing techniques:

Design Freedom: One of the most significant benefits of 3D particle printing is the ability to create intricate designs that would be difficult or impossible to achieve with conventional methods. This is particularly useful in industries like aerospace and biomedical engineering, where customized parts can lead to improved performance and enhanced functionality.

Material Efficiency: The layer-by-layer approach not only reduces waste but also allows for the use of advanced materials that enhance the properties of the final product. For instance, manufacturers can utilize composites or alloys that are specifically engineered for specific applications.

Rapid Prototyping: 3D particle printing streamlines the prototyping process. Designers can quickly create functional prototypes that closely represent the final product, allowing for faster iterations and more efficient testing.

- Flexibility in Production: This technology allows for both small batch production runs and one-off custom products. Manufacturers can adapt to market demands without the need for large upfront investments in molds and tooling.

Applications of 3D Particle Printing

3D particle printing holds promise across numerous industries. A few notable applications include:

Aerospace: The ability to create lightweight, complex parts is invaluable in the aerospace sector. Components such as fuel nozzles, brackets, and other structures made using 3D particle printing can significantly reduce weight without compromising strength, leading to improved fuel efficiency.

Healthcare: In medicine, 3D particle printing is used to create custom implants and prosthetics tailored to individual patients. This customization can lead to better outcomes and enhanced compatibility with the human body, improving both function and comfort.

Automotive: Automotive manufacturers are increasingly leveraging 3D particle printing for rapid prototyping and the production of end-use parts. This allows for innovation in design and manufacturing processes, ultimately leading to faster development times and reduced costs.

- Consumer Goods: From household items to fashion accessories, 3D particle printing enables brands to produce unique products that stand out in a crowded marketplace. Small businesses and startups can quickly deploy custom designs to meet niche demands.

Challenges of 3D Particle Printing

Despite its advantages, 3D particle printing faces several challenges that need to be addressed for broader adoption:

Material Limitations: While there is a range of materials available for 3D particle printing, finding the right powder for specific applications can sometimes be difficult. Ongoing research is necessary to develop new materials that offer better performance and characteristics.

Technical Complexity: The technology requires a deep understanding of both the printing process and material science. Operators must be skilled in handling machines and optimizing parameters to ensure the best results.

Post-Processing Requirements: Many particle printing methods require extensive post-processing, which can add time and costs to production. Finding ways to minimize these processes is vital for the future of the technology.

- Quality Control: Maintaining consistent quality can be a challenge, as variations in materials, environmental conditions, and printer settings can all impact the final output.

Future Directions for 3D Particle Printing

The field of 3D particle printing is rapidly evolving, with numerous research initiatives underway to push the boundaries of what’s possible. Some trends to watch include:

Material Innovation: Ongoing developments in particle materials, including bio-based, composite, and high-performance alloys, will expand the range of applications for 3D particle printing.

Automation and AI: As manufacturing processes increasingly incorporate automation and artificial intelligence, 3D particle printing systems will likely become more intelligent, optimizing their operations for speed and efficiency.

Integration with Other Technologies: We may see further integration of 3D particle printing with other manufacturing technologies, such as traditional machining or injection molding, to create hybrid processes that leverage the best aspects of each.

- Sustainability Efforts: In response to growing environmental concerns, the industry is likely to focus more on sustainable practices, developing materials and processes that minimize waste and reduce overall energy consumption.

Conclusion

3D particle printing represents a significant advancement in additive manufacturing that promises to reshape various industries by enabling creativity, customization, and efficiency. As technologies and materials continue to evolve, we can expect this innovative approach to broaden its horizons, providing businesses and consumers with unprecedented opportunities for innovation and design. Embracing this technology could lead to not only improved products but also a more sustainable and responsive manufacturing landscape. Understanding the fundamentals of 3D particle printing is crucial for anyone interested in the future of manufacturing, design, and technology.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.