Recently, Mohou.com learned that The Drone Bird Company, a Dutch technology company, was using 3D printing technology to help it produce its bird-shaped drones. The company leverages additive manufacturing technology and expertise from 3D printer manufacturer EOS and its subsidiary Advanced Laser Materials (ALM), as well as additive manufacturing service provider Partson Demand, to achieve faster delivery times and reduced production costs. versatility. This partnership means that The Drone Bird Company can launch more products faster and be more flexible to meet the needs of different customers.

The combination of EOS’s Selective Laser Sintering (SLS) technology and ALM’s lightweight PA 640-GSL carbon material enables 3D printing of drone fuselages and various cowlings. Drone Bird is designed to accurately mimic the appearance of a raptor and is primarily used for bird prevention and control, with applications across several sectors including agriculture and aviation.

In an interview with Parts on Demand, Jan-Willem Van den Eijke, CEO of Drone Bird, said: “Additive manufacturing allows us to be pioneers in terms of materials, shapes and wall thicknesses, which For example, it allows us to modify designs more quickly. rapid development of Drone Bird and allows us to respond more quickly to specific problems and applications.”

Main applications of Drone Bird

The drone prototype was originally designed to support the master’s thesis project of Twente student Nico Nijenhuis, and its practicality and success quickly transformed it into a full-fledged commercial product. Drone Bird is mainly used in bird prevention and control measures in the aviation industry. According to the Federal Aviation Association (FAA), bird strikes and disturbances cost up to $500 million in damages each year, with 15,400 strikes occurring in 2021 alone. The drone’s realistic design, similar to that of ‘a hawk, makes it particularly effective in deterring populations of wild animals and birds at airports. Due to the reality of drones, birds react instinctively and this avoidance instinct is heightened. Therefore, Drone Bird can provide sustainable and long-term bird repellent measures in designated locations.

The agricultural sector is another key sector using these drones. Birds cost the Dutch agricultural sector more than 90 million euros each year. Therefore, the powerful bird repellent effect exhibited by this drone is particularly attractive to those in the agricultural sector. Additionally, the addition of a high-definition camera to the Drone Bird drone can also be used to monitor livestock, deter predators, and remotely inspect irrigation systems.

△Drone Drone Bird in the shape of a falcon. Image of the company Drone Bird。

Using additive manufacturing to optimize development and production

Drone Bird was originally made by hand from fiberglass and epoxy resin. However, throughout the initial manufacturing and production of the drones, the process became significantly inefficient and was seen as driving down profit margins. Therefore, in order to optimize the production process, Parts on Demand and ALM have collaborated to provide expertise in additive manufacturing and rapid prototyping (RP) research and development of thermoplastics.

ALM PA 640-GSL, a carbon fiber and glass filled material based on PA12, is often used to produce 3D printed parts. The material offers high strength and stiffness, high thermal stability, buoyancy, high-quality Sunfish finishes and details, and uses an average of 10% less material per construction. As a result, parts 3D printed with this material are not only durable enough to withstand harsh weather and environmental conditions, but are also cheaper to manufacture because less material is needed for each build.

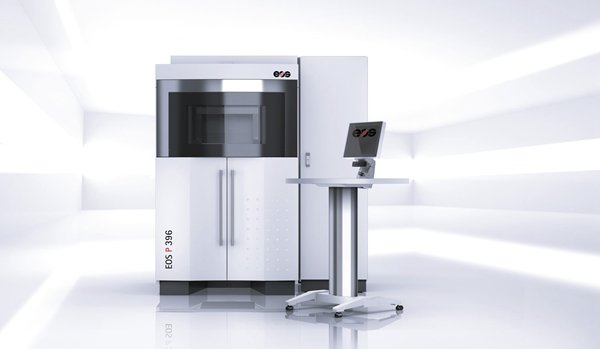

Using the ALM PA 640-GSL, combined with the EOS P 396 SLS 3D printer, Drone Bird was able to accelerate the development phase and produce parts with greater precision. In fact, the speed with which parts can be manufactured and tested makes prototyping even faster. Additionally, after integrating 3D printing into the production process, the company can now consider and test different additive manufacturing materials. This allows the company to take on new challenges and pursue new product ideas while maintaining design freedom in terms of shape, material properties and wall thickness.

△EOSP 396 system. Photo of EOS

3D printing drone

The commercial drone market is growing and is a valuable market for additive manufacturing companies to exploit. For example, DroneIndustry Insights notes that the total value of drone investments in the United States almost tripled, from $2.4 billion in 2020 to $7 billion in 2021.

In 2021, agtech startup Dragontech began using additive manufacturing technology to develop a drone-based data collection platform to help farmers monitor and identify problems in their fields. The company uses MakerBot 3D printers to design and prototype parts that can be used to attach its systems integration platform to commercially available drones. “We want to be able to integrate almost any type of sensor onto a drone and put it all in a ready-to-use platform so anyone can use it,” said Mel Wieting, founder of Dragontech.

Separately, the Royal Air Force (RAF) is developing an air attack unit containing 3D printed drones starting in 2022. These drones are equipped with munitions and can be deployed in swarms to destroy designated targets. The project, which reportedly cost £4million, also resulted in the development of a 3D printed double-knife device called ‘Pizookie’. Sir Mike Wigston, the current head of the British Air Force, says these 3D printed drones have huge potential to overwhelm and confuse enemy air defense systems.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.