Design for additive manufacturing (DfAM) refers to the design process in which structural design engineers use the unique benefits of additives to manufacture products. This requires design engineers to always consider the impact of additive manufacturing process constraints on the design throughout the design process.

With the popularization of the application of additive manufacturing, the advantages of additive manufacturing in product design have become more and more obvious, such as lightening parts, merging multiple parts into one, and improvement of mechanical properties. Every time you design an additive product, it’s a thought process. In this process, careful program decisions must be made, not only based on design criteria, but also many light weight and mechanical performance requirements.

As manufacturing companies around the world pay more and more attention to additive manufacturing, it becomes increasingly important to have product parts specifically geared toward additive manufacturing when conditions permit. However, additive manufacturing has little importance in many conventional parts that require mold opening, additive manufacturing will save a lot of costs during the experimental phase. For example, additive manufacturing allows significant savings. be visible from the first design phase.

In the field of additive manufacturing, there are different levels of design, which directly replace the manufacturing process of parts, modify the smallest details of parts to adapt to the additive manufacturing process, and design specifically for additive manufacturing. The results are different, of course the last aspectAMThe design is the best choice among the three. It not only achieves lightness, but also improves the mechanical properties of the parts, as well as the ease of assembly and the size of the space occupied.

Additive manufacturing adds value to products

ForGDTAs for metal printing, the cost of additive manufacturing process is very high, and its manufacturing method can only adopt a “mass” production method. Compared with traditional conventional manufacturing technology, the speed of additive manufacturing is very slow, therefore. we should use additive manufacturing when it adds value to products.

During the product design stage, engineers need to analyze the structure of the whole product and the impact of part configuration, and then confirm the manufacturing process of the components. For example, choosing additive manufacturing can maximize product benefits. then carry out the manufacturing process on the parts. Specialized additive manufacturing process design.

Additive manufacturing processDfAMApplication in design

1) Direction of molding

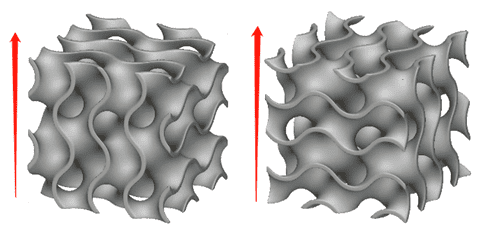

When we design parts for additive manufacturing, we must take into account the process limitations of the different materials in the part. The shape of the part must also be changed depending on the limitations of the process. the direction of molding of the material on the part. For example, the three-period minimum surfaceGyroidUnit cell, as shown below1-Gyroiddisplayed in the unit cell.

picture1-Gyroidunit cell

When printing, the printing direction is the direction of the red arrow. If you follow the border method in the left picture, the printed effect will be very smooth, and the printing risk is also very low. The printed effect of the side border will be rough, and the risk of collapse is also very high, as shown below.2- GyroidAs the unit cell sample shows, the left side of the unit cell in the picture extends in the direction of printing molding and is very delicate and smooth. On the right side of the image there are more transverse spans and the effect is obviously very crude. Therefore, it is also very important to consider the forming direction during the design process.

picture2- GyroidUnit cell specimen

2) Clean powder

againstGDTIn terms of process, when designing parts and products, the problem of cleaning parts after printing parts must also be considered. It is necessary to at least ensure that the minimum deviation of the parts cannot be less than a specific value, and different. minimum openings should be selected for different materials. Of course, sometimes when there is a conflict between performance and technology, a compromise solution must be adopted.

3) Forming span

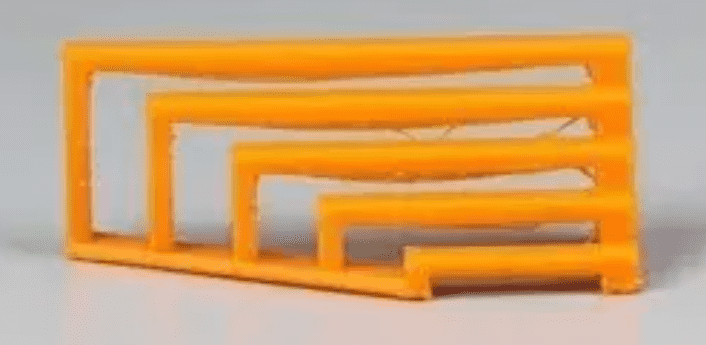

The longest span surface of the workpiece will be very rough as shown in the figure3-Unsupported bridge shown.

picture3-unsupported bridge

in the photo above3It can be seen that the larger the horizontal span, the more difficult it is to form. The surface quality of the descending part will be very poor, the structure is very fragile, and the powder spreading device may even be damaged.

4) Component orientation

There are many reasons to constantly consider the different print directions of the part when designing, to ensure the part can be printed, as well as the amount of support, strength, surface quality and properties of the material. In this way, the printing direction can also be changed according to the mechanical boundary conditions of the part to avoid various strength problems caused by the anisotropy of the part. The impact on metal printing is relatively low and it can be heat treated or otherwise. post-processing. Processes such as hot isostatic pressing.

historical case

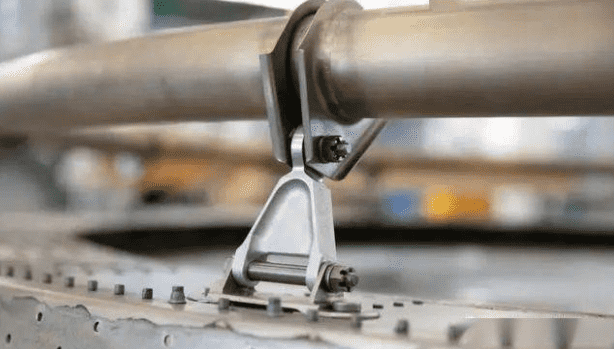

This year6moon13Today, the application of additive manufacturing in the field of aviation has once again marked the beginning of a landmark development, led by Lufthansa Technik of Germany.3DMetal additive manufacturing support developed by the Printing Technology Center”Link A” Obtained official airworthiness certification from the European Union Aviation Safety Agency. As shown below.4-A-Link3DPrint the support.

picture4-A-Link3DPrint media

Previously, this part was manufactured using traditional forging processes. Its main function was to attach an annular hot air channel to the engine air intake cover.9individualLink AComponent. Vibrations may occur when the engine is running, causingLink AThis causes wear at the mounting holes, so parts need to be replaced from time to time.

The main loads on this part are tension and compression, and there is a small amount of bending and shear loads. Such a unique force boundary condition has become the first choice of additive manufacturing personnel.

In addition, its safety redundancy is also very important, because each motor has9individualLink Aparts, Airbus support is made up of4The parts are arranged in parallel, so if one part fails during flight, it will not cause a fatal problem.

Parts of this type are designed to be lightweight through topology optimization, which also saves mold cost and mold customization time. For parts in low demand, which must be light and easy to carry, additive manufacturing is used. the process brings Many opportunities presented themselves.

Additive manufacturing is in a state of rapid development and evolution. In the future, there will be more new technologies, new software and new materials to enrich the additive manufacturing industry, and there will also be more companies and schools to invest in additive. the industry will be one worth looking forward to.

author:

Li Rui Peng Structural design engineer He has extensive project experience in additive manufacturing design. It performs lightweight structural design of parts based on simulation topology results and uses unit cells with minimum three-period curved surfaces to design heat exchanger structures. . For additive process optimization.

Source: Chinese 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.