thermoplastic polyurethane(TPU)HAS 1937 Created in a German laboratory in 1999, it has become one of the most widely used plastic materials in industrial manufacturing. Considering the attractive combination of thermoplastics and rubber in a variety of necessary applications, it’s easy to see why. TPU exist 3D Printing is very popular alongside other traditional types of manufacturing like injection molding.TPU The versatility of comes from the combination of hard and soft segments that make up its block polymers, in line with the evolution of today’s manufacturers towards 3D Most common reasons for printing: versatility and customization.

3DPrintTPUBenefits :

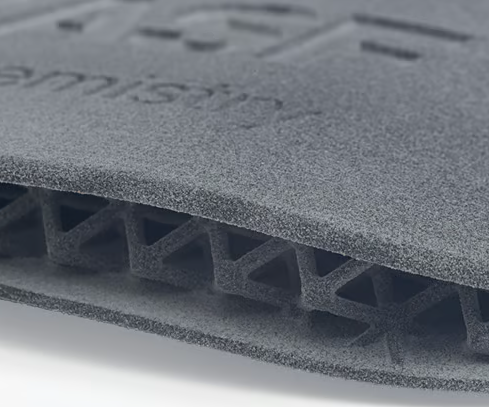

magic monkey networkAvailable in off-white TPUto use EOS 3D Printer for selective laser sintering (SLS)and BASFUltrasint TPU01material, gray, used Multi Jet Fusion 3D Model printer. These materials offer several advantages over other elastomers, including:

Excellent tensile strength: Tensile strength is defined by the stress a part can withstand before breaking, called MPa. (MPa) unit of pressure to be measured.TPU With up to 60 MPa The high tensile strength, combined with good flexibility, can be used in high-performance parts that need to withstand rigorous use.

Elongation at break:This material property is tested by comparing where the part breaks after tension to its original length.TPU It is known for its high elongation at break due to its elasticity, which makes it particularly useful in critical applications as it is also very strong.

Excellent load capacity:This is an important measure because it demonstrates 3D The weight that the printed material can support – a factor that can be extremely important for applications that require durable, high-performance products, including mechanical equipment such as pipes, hoses and joints.

Tolerance: TPU Due to its natural tolerance, it is able to withstand many different elements, which is why it is considered a versatile product. 3D Printing equipment. This includes resistance to chemicals, oils and greases, weather, heat and abrasion.

Typical Thermoplastic Polyurethane Applications

car

While the automotive industry has used it for decades in prototyping and functional parts inside and outside of vehicles, 3D print but TPU Enables the design of components focused on driver comfort, such as custom headrests and seats.TPU Textures can vary from soft and luxurious to harsh and practical, depending on the vehicle’s interior components. There are also many different finishes available for automotive applications.

consumer accessories

3D The printing industry is known for providing consumers with more choice when it comes to accessories, largely due to the enormous potential offered by increased design freedom and customization capabilities. This is especially true for items like smartphone cases, where customers can fully personalize items, adding an exciting and unique touch to an item that is almost impossible to live without.TPU It is also a great option for adding quality and customization to highly functional items used daily, such as products like mats and rubber grips.

shoe

3D Printing has a huge impact on many levels of the footwear industry. Designers working in the studio or at home can create innovative, eco-friendly designs on demand and send them to Shapes to drive 3D Printing services. Large companies use TPU and other materials to maximize the design of an epic, futuristic running shoe with a host of features designed to push athletes and everyday wearers towards comfort and endurance.

The shoes also have incredible potential for personalized fit, starting with the ability to 3D Printed insoles for added support and a balanced gait, as well as orthotics that can easily adjust and resize as needed. pass 3D Rapid production of prints can create shoes that are more durable, more flexible and lighter.

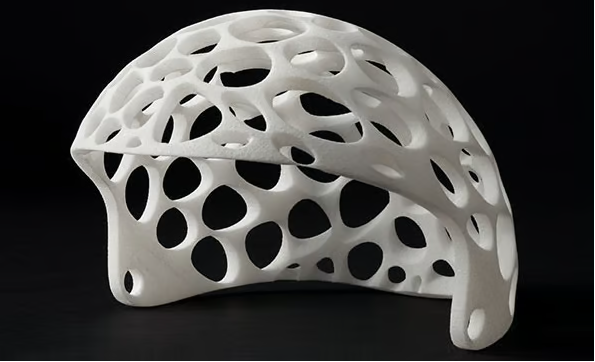

medical equipment

TPU Yes 3D Another area where printing is having a huge impact is in the production of many medical devices with complex and lightweight geometries, which was previously impossible with traditional manufacturing. Products such as stents, prostheses and implants can be purchased from 3D Print to provide patients with safe, personalized devices that can withstand long-term daily use without causing skin irritation.

robotics

TPU Also suitable for robotics, especially softer applications that may require highly flexible components such as connectors, actuators and simulated flexible fingers, arms and grippers to perform tasks on a manufacturing line or at the individual level. The material could also be used in mobile robots and potentially perform autonomous tasks. 3D Print mobile tires and other accessories.

sporting goods

Due to the protective nature of sports equipment,3D TPU Printing technology can play a very important role in preventing injuries among athletes.3D Printed protective gear uses mesh structures to improve internal strength and can include helmets, guards and more, all of which can be heavily customized for the comfort and safety of the athlete.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.