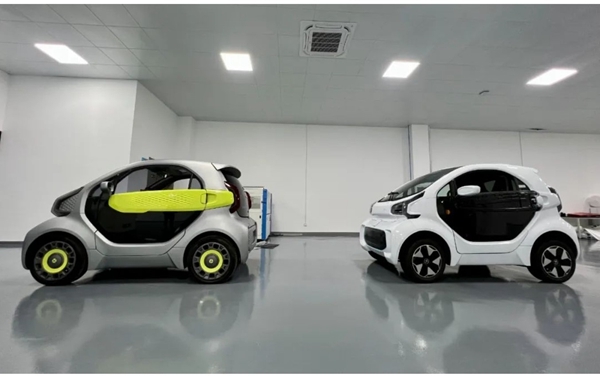

According to Mohou.com,8moon9In the afternoon of the same day, in the Changbai Science and Technology Park of Xinzhan High-Tech Zone, a light electric vehicle with a smooth appearance——XEV-YOYOparked in the exhibition hall of Hefei Youyao Technology Co., Ltd. As the flagship product of Hefei Youyao,XEV-YOYO“born” in3DPrinting technology, it is the world’s first use of vehicle body interior and exterior trim parts3DPrinting technology for mass production of electric cars.

The world’s first interior and exterior vehicle body trim parts3DPrinting technology for mass production of electric cars——XEV-YOYO。

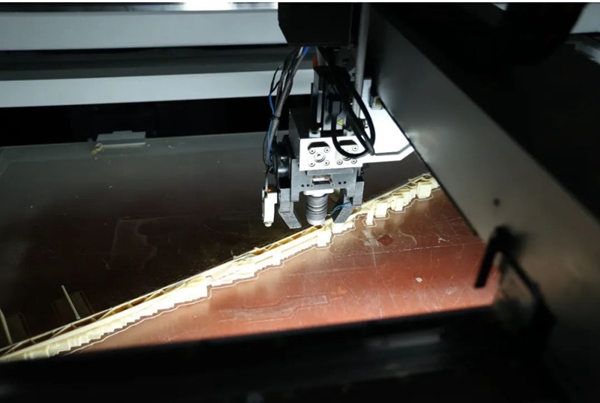

“3DPrinting cars takes less time and costs less to produce. From component design to production, a car needs very little.2Weekly time, ordinary car time is3~6About months. “Presented by Wu Jiawei, Director of Additive Manufacturing of Hefei Youyao Technology Co., Ltd.

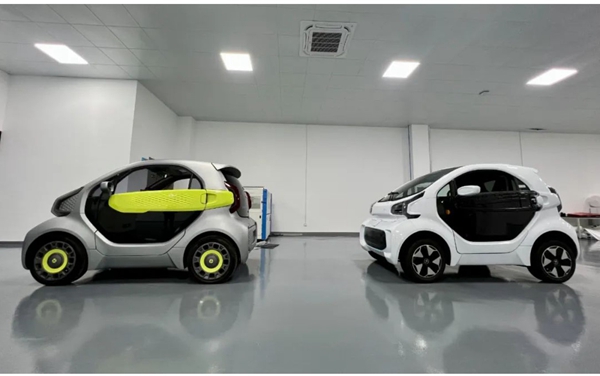

XVElectric vehicles do not need the molds used in traditional automobile manufacturing and can truly realize flexible and personalized production on demand, reducing vehicle development time and investment costs.80%above. Currently, Hefei Youyao has completed the design of the door panels, front faces and rear fenders.3DPrinting and production are still unlocking the “printing” of various automobile parts.

A fully loadedXEV-YOYOthe longest battery life can reach150kilometers, the maximum speed can reach approximately80kilometers per hour. When the power runs out, go to the designated place to replace the battery.3-5Complete battery swap in minutes; or use a household charging battery,3~4Can be fully charged in a few hours. In major European countries, urban travel, short-distance travel, transporting children to and from school… this intelligent electric car has entered a rich life scene.

The world’s first interior and exterior vehicle body trim parts3DPrinting technology for mass production of electric cars——XEV-YOYOSome custom body parts.

“‘Xinping Auto Heji Lifelong Wisdom’, in the field of new energy vehicles, Hefei has the advantages of supply chain and R&D talents.”2020Year11In September, Hefei Youyao settled in Xinzhan high-tech zone, with full investment6billion.2021annual2month, first batch3DTotal number of sample cars printed40The unit has been successfully delivered. Today, Hefei Youyao has50round3Dprinters, which can be produced per year3000~4000electric car. at present,XVThe company independently developedYOYO 3DPrinting the complete vehicle platform for electric vehicles, including chassis system, body electronic system, suspension system and other complete vehicle body structure as well as interior and exterior decoration design. Complete vehicle3DPrinting can not only improve the integrated strength of the body, but also customize the “skin”.

“This year’s sales volume is double that of the same period last year, which can meet the personalized needs of small groups of customers.” Next year, popular abroadXEV-YOYOWill be sold simultaneously in the country, broadband versionXEV-YOYOThe maximum speed will reach 1 hour100kilometers and can be driven on intercity highways. Interior, seats, etc. of the car will be adjusted to improve comfort and functionality to bring it into line with Chinese driving habits.

3DThe printer printsXEV-YOYOInterior and exterior body trim parts.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.