The Evolution of Control Units in Intelligent Manufacturing

The intelligent manufacturing unit is the minimum basic unit for the construction of an intelligent factory, and the heart of the intelligent manufacturing unit is its main control unit, which is equivalent to the brain of the intelligent manufacturing unit, giving the collection and management of data from the intelligent manufacturing unit, to the monitoring and planning of equipment, to remote communication, to intelligent decision-making, and even the ability to evolve intelligently. In this article, we will focus on the technical characteristics and functions of PLC, IPC, and PAC, as well as their applications in intelligent manufacturing.

PLC: Programmable Logic Controllers

A PLC (Programmable Logic Controller) is a type of control unit that is mainly focused on controlling logic and control with several points. In simple equipment, such as the entry-level distribution machine, packaging machine, and production line control, PLC is used. Since the computing power needs are not high, most of them are based on MCU (Microcontroller Unit) or ARM (ARM) designed. When the computing power is insufficient, DSP (Digital Signal Processor) is used, and when it is not rich, FPGA (Field-Programmable Gate Array) is used.

PLC’s performance depends on dedicated equipment, and the execution of applications is carried out by dedicated material planes. In fact, speed, reliability, and functions cannot be compared to general operating systems in real time, which leads to the specialization and overall performance of the automaton. The execution of the PLC user application is implemented via the equipment, and we see most of the planes dedicated on the market and that there is not much reusability.

IPC: Industrial Personal Computers

An IPC (Industrial Personal Computer) is a type of computer that is widely applicable to computers in non-family personal environments, such as all-in-one factory and head-up screens. However, in the Core Control Control field, this type of machine cannot be used in many cases. It has higher requirements for reliability, stability, and electrical parameters. Although it is somewhat similar in appearance, there are qualitative differences in interface treatment, physical wiring, and software requirements.

PAC: Programmable Automation Controller

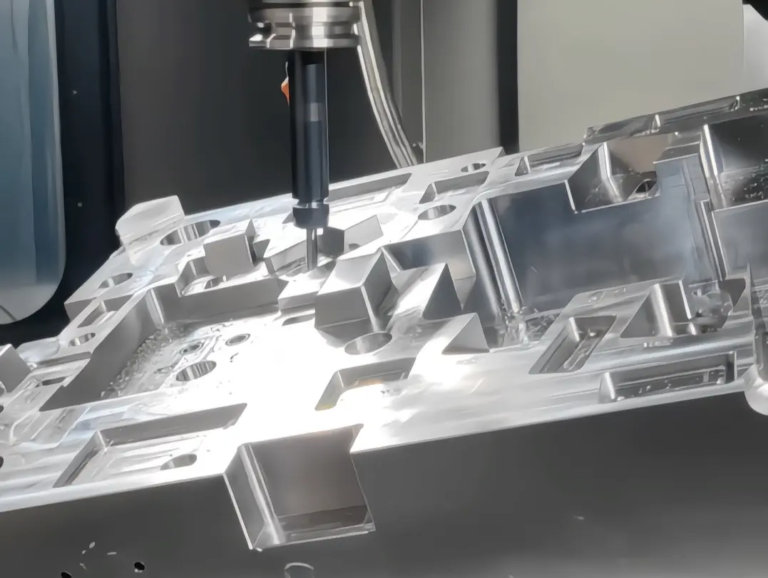

A PAC (Programmable Automation Controller) is a type of control unit that has not only logical control but also focuses on movement control. The mobile unit is connected to various industrial bus interfaces, making it a product for more complex industrial equipment, such as semiconductor equipment, high-speed printing equipment, 3D printing equipment, etc.

Choosing Between PLC, IPC, and PAC

When choosing between PLC, IPC, and PAC, several factors need to be considered, including budget, size, support, complexity, and future scalability. For example, if the production is not affected, or when several redevelopment of devices may be received, the computer system can use IPC. When it can affect production speed and quality, its equipment can use PLC or PAC. If the production line is mainly logically controlled, using PLC is recommended.

In terms of automation, for high automation and high reliability (such as semiconductor production equipment, industrial print presses, etc.), using PAC products is recommended. The easier way is to see what you need to control: the number of axes, below 8 axes, versatile API, and PAC with more than 16 axes.

In addition to traditional PLC, PAC, and IPC controllers, with the development of Industry 4.0, EDGE programmable industrial controllers are gradually playing a huge impact in the fields of intelligent manufacturing and the industrial Internet. In the next issue, we will focus on what magic intelligent controls can be obtained by EDGE computer controllers.

Conclusion

In this article, we have discussed the technical characteristics and functions of PLC, IPC, and PAC, as well as their applications in intelligent manufacturing. By understanding the differences between these control units, we can choose the right one for our specific needs. As we move forward in the era of Industry 4.0, it is essential to stay informed about the latest developments in control technology and their applications in intelligent manufacturing.