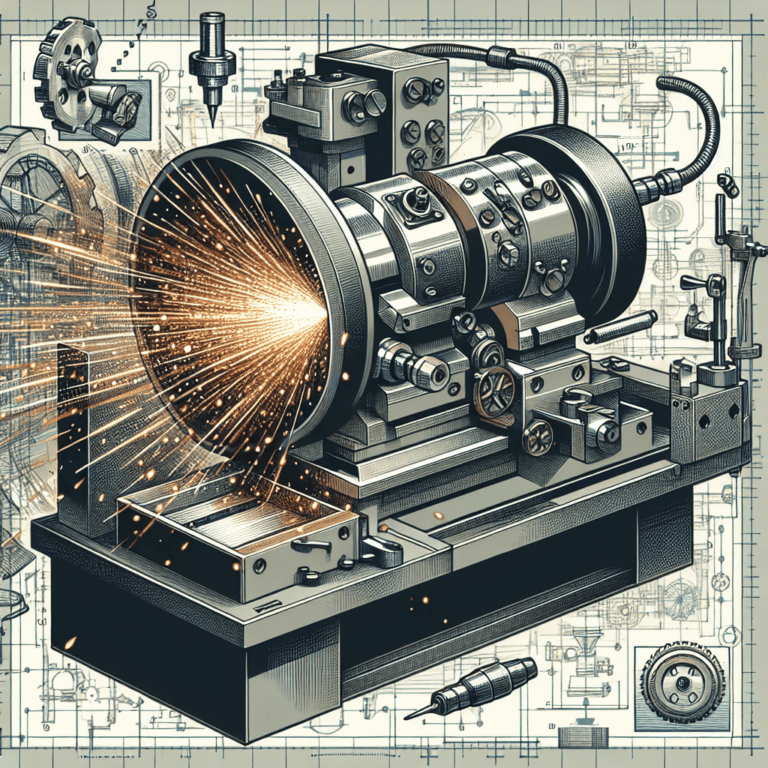

Understanding the Processing Process of Fully Automatic Centerless Grinders

In the realm of precision manufacturing, the importance of surface finishing and dimension accuracy cannot be understated. Among the tools designed to achieve these objectives is the fully automatic centerless grinder. This sophisticated piece of machinery is essential for industries requiring high production rates while maintaining precise specifications. This article delves into the technical key points of the processing process of fully automatic centerless grinders, shedding light on their operational mechanisms, advantages, and applications.

The Fundamentals of Centerless Grinding

Centerless grinding is a machining process that has gained significant traction in various industries due to its efficiency and precision. Unlike traditional grinding methods, where the workpiece is held in place between two centers, centerless grinding allows the workpiece to lie freely between the grinding wheel and the regulating wheel. This unique setup enables continuous production without the need for intricate setups that are typical in other grinding operations.

Key Components of Fully Automatic Centerless Grinders

Understanding the architecture of fully automatic centerless grinders is crucial for recognizing their operational efficiency. Key components include:

1. Grinding Wheel

The grinding wheel is the primary tool used for material removal. It is typically made from abrasive materials and designed to deliver high surface finish qualities.

2. Regulating Wheel

This wheel controls the speed of the workpiece and its feed rate. Its surface is less abrasive compared to the grinding wheel, ensuring precise control over the workpiece’s rotational velocity.

3. Workrest Blade

The workrest blade supports the workpiece, ensuring stability during the grinding process. It must be adjusted accurately to maintain the desired height and angle.

4. Automatic Feeding System

This system automates the feeding of workpieces into the grinding area, optimizing cycle times and reducing the manual labor involved in handling parts.

5. Control Panel

The operator interface allows for monitoring and management of the grinding process, including adjustments to parameters like speed, feed rate, and grinding time.

The Processing Steps in Fully Automatic Centerless Grinding

The operation of a fully automatic centerless grinder can be broken down into several steps, each of which is critical for ensuring optimal performance and quality.

1. Loading the Workpiece

The process begins with the automatic loading of the workpiece. Advanced feeders or conveyor belts facilitate this step, minimizing the risk of manual error and increasing throughput.

2. Alignment and Adjustment

Once loaded, the workpiece is aligned between the grinding and regulating wheels. This step is crucial; proper alignment results in uniform grinding and prevents damage to the workpiece. Automatic adjustment mechanisms can fine-tune the position without requiring human intervention.

3. Grinding Cycle Initiation

With the workpiece in position, the grinding wheel engages. The controlling software regulates the grinding parameters, such as wheel speed and feed rate. This automated cycle is continually adjusted based on real-time data, ensuring efficient stock removal while maintaining surface integrity.

4. Monitoring and Feedback Mechanisms

As the grinding process proceeds, various sensors monitor parameters such as temperature, grinding pressure, and surface finish. Feedback from these sensors is integrated into a control system that can make adjustments on-the-fly. This dynamic feedback loop is essential in achieving the desired tolerances and surface finish.

5. Quality Control

After the grinding cycle, the workpieces are often subjected to rigorous quality control checks. Automated optical inspection systems can quickly ascertain the quality of surface finishes and dimensions, allowing for immediate corrections if deviations are detected.

6. Unloading and Packaging

The final step involves the automatic unloading of the finished workpieces, which are then either sent to a packaging system or moved directly to the next phase of the manufacturing process. Automated systems ensure that this operation is streamlined to reduce idle time.

Advantages of Fully Automatic Centerless Grinders

The automation of the centerless grinding process brings several advantages:

1. Increased Productivity

The fully automatic systems significantly increase throughput compared to manual or semi-automatic systems. Continuous operation reduces cycle times, enabling manufacturers to meet higher production demands.

2. Consistent Quality

With automation, the inconsistencies associated with human operation are minimized. The integration of sensors and real-time adjustments ensures that the quality remains consistent batch after batch.

3. Reduced Labor Costs

Fully automatic operations require fewer personnel compared to traditional methods, resulting in lower labor costs and the ability to allocate staff to other value-added tasks within the manufacturing process.

4. Enhanced Precision

The combination of advanced control systems and precise machinery leads to improved accuracy in dimensions and surface finishes, which is particularly critical in industries such as aerospace, automotive, and medical manufacturing.

Applications of Fully Automatic Centerless Grinders

Fully automatic centerless grinders are widely applied in various sectors, underscoring their versatility:

1. Automotive Industry

In automotive manufacturing, centerless grinding is employed for producing precision components such as shafts, bearings, and other critical parts where dimensional accuracy and surface finish are paramount.

2. Aerospace Sector

The aerospace industry utilizes centerless grinding for components that require strict tolerances and high-performance standards, including turbine shafts and hydraulic rods.

3. Medical Devices

For the medical device industry, centerless grinders are essential in producing precision instruments and implants, where reliability and performance are crucial.

Conclusion

Fully automatic centerless grinders represent the forefront of grinding technology, integrating advanced automated systems with precision machining capabilities. Their ability to improve productivity, ensure consistent quality, and reduce operational costs makes them an invaluable asset in modern manufacturing environments. As industries continue to evolve and demand higher precision and efficiency, the role of centerless grinding is sure to expand. Understanding the technical points of this processing process not only helps manufacturers make informed decisions about their production capabilities but also aids in optimizing the entire manufacturing workflow. By leveraging these advances, companies can enhance their competitiveness and ensure they meet the rigorous standards of today’s production demands.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.