In the realm of modern manufacturing, where demands for high strength, lightweight components, and complex geometries converge, the ability to machine high-performance alloys with precision and reliability is paramount. This is the domain of Strong CNC Alloy Machining Services, a specialized discipline that goes far beyond standard metal cutting. It represents a sophisticated interplay of advanced machinery, deep material science knowledge, and meticulous process engineering to transform tough, often exotic, alloy materials into mission-critical parts.

H2: Decoding “Strong” in CNC Alloy Machining

The term “strong” here is multifaceted. It doesn’t merely refer to the brute force of the machine but encapsulates the entire service’s capability to handle challenges that would overwhelm conventional machining setups.

Material Strength: The primary challenge. We’re discussing alloys like:

Titanium Alloys (e.g., Ti-6Al-4V): Prized for their exceptional strength-to-weight ratio and corrosion resistance, but notorious for poor thermal conductivity, leading to rapid tool wear and heat-affected zones.

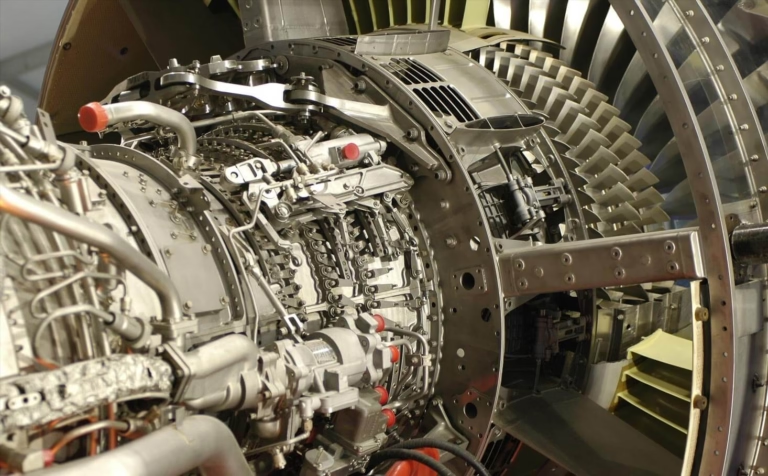

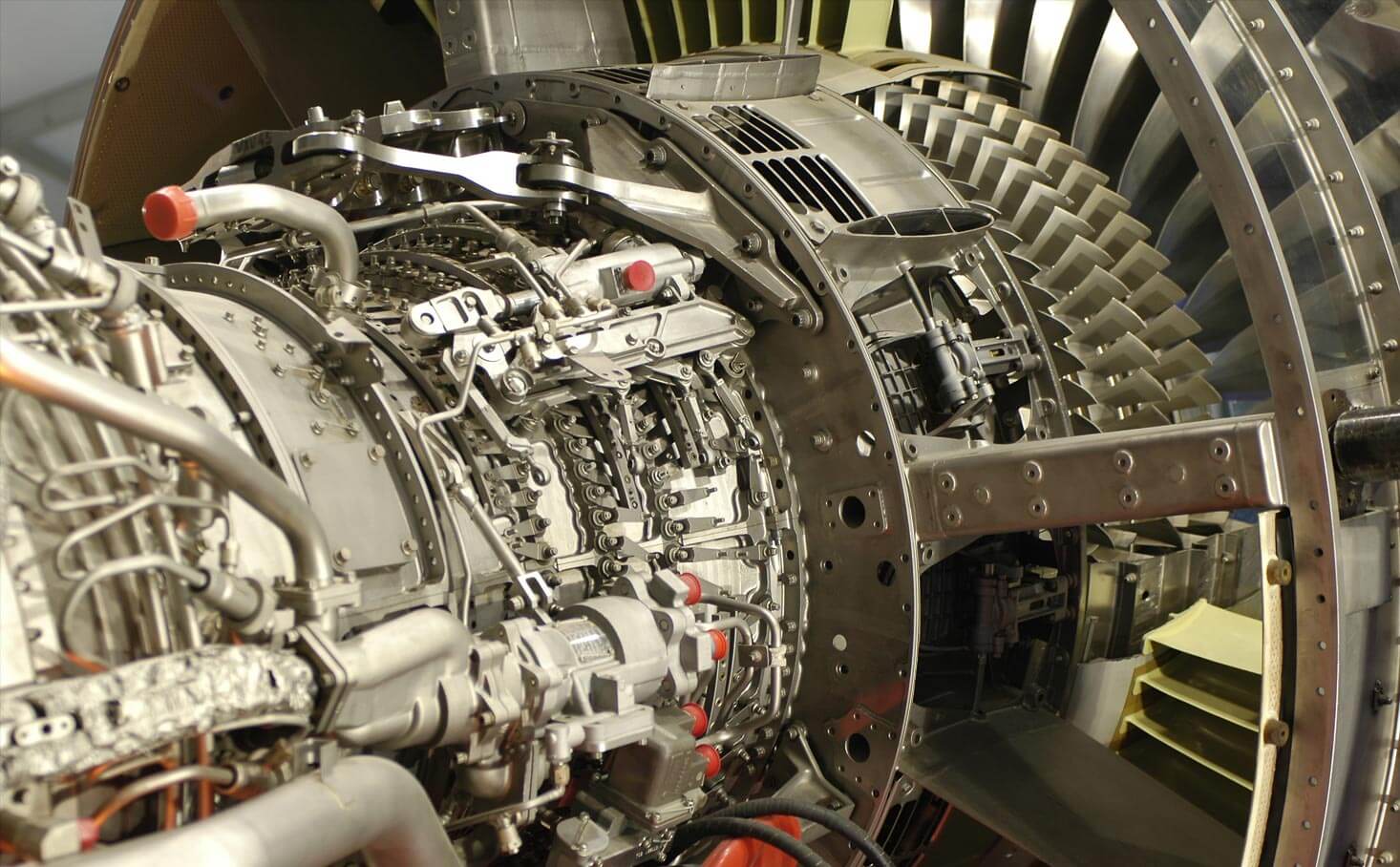

Inconel, Waspaloy, and other Nickel-Based Superalloys: The workhorses of aerospace and power generation, capable of retaining strength at extreme temperatures. Their work-hardening characteristics make them incredibly difficult to cut.

High-Strength Aluminum Alloys (e.g., 7075, 2024): While more machinable than titanium or nickel alloys, achieving optimal strength (often through precise thermal treatment post-machining) and maintaining dimensional stability requires expert handling.

Tool Steels and Stainless Steels (e.g., 17-4PH, 15-5PH): Offering high strength and corrosion resistance, they demand strategies to prevent work hardening and achieve fine surface finishes.

Process Strength: This is the backbone of the service. It involves:

Dynamic Rigidity of Machines: Machines must possess exceptional damping characteristics and structural integrity to withstand the high cutting forces and vibrations generated when machining hard alloys without sacrificing accuracy.

High-Pressure Coolant Systems: Essential for evacuating chips and managing the intense heat at the cutting interface, especially for materials like titanium.

Advanced Toolpath Strategies: Utilizing trochoidal milling, high-efficiency milling (HEM), and other adaptive paths to maintain constant chip load, reduce tool stress, and manage heat generation.

In-Process Monitoring: Utilizing probes and sensors to ensure consistency and catch deviations in real-time, which is critical for expensive alloy workpieces.

Technical Strength: The human and analytical element. This includes metallurgical expertise to understand material behavior, CAM programming skills to optimize for specific alloys, and experience in selecting the correct cutting tools (substrate, coating, geometry) and parameters (speed, feed, depth of cut).

H3: The Critical Role of 5-Axis CNC Machining in Alloy Fabrication

When dealing with complex, high-strength alloy components—such as aerospace structural brackets, turbine blades, or medical implants—5-axis CNC machining transitions from an advantage to a necessity. Here’s why it’s indispensable for strong alloy machining:

Single-Setup Complexity: Complex parts can be completed in one setup on a 5-axis machine. This is crucial for alloys because every time you re-fixture a part, you introduce potential for error and, more importantly, may lose the precise datum reference needed for tight tolerances. Minimizing setups maximizes accuracy for these valuable materials.

Optimal Tool Orientation: The ability to continuously orient the cutting tool perpendicular to the workpiece surface allows for:

Use of shorter, more rigid cutting tools, which drastically reduces vibration and tool deflection—a key to achieving fine surface finishes and holding tight tolerances in tough materials.

Maintaining ideal cutting conditions across contoured surfaces, extending tool life when machining expensive, wear-resistant tooling.

Machining of Complex, Organic Geometries: For components like impellers, monolithic aerospace frames, or conformal-cooled molds made from high-strength alloys, 5-axis is the only practical method to access all necessary features without costly and time-consuming custom fixtures or secondary operations.

A service provider’s mastery of 5-axis CNC machining is often the clearest indicator of its capability to deliver true Strong CNC Alloy Machining Services.

H4: Beyond Cutting: The Full-Spectrum Service for Alloy Components

A robust service doesn’t end at the CNC machine. It encompasses a full spectrum of value-adding processes:

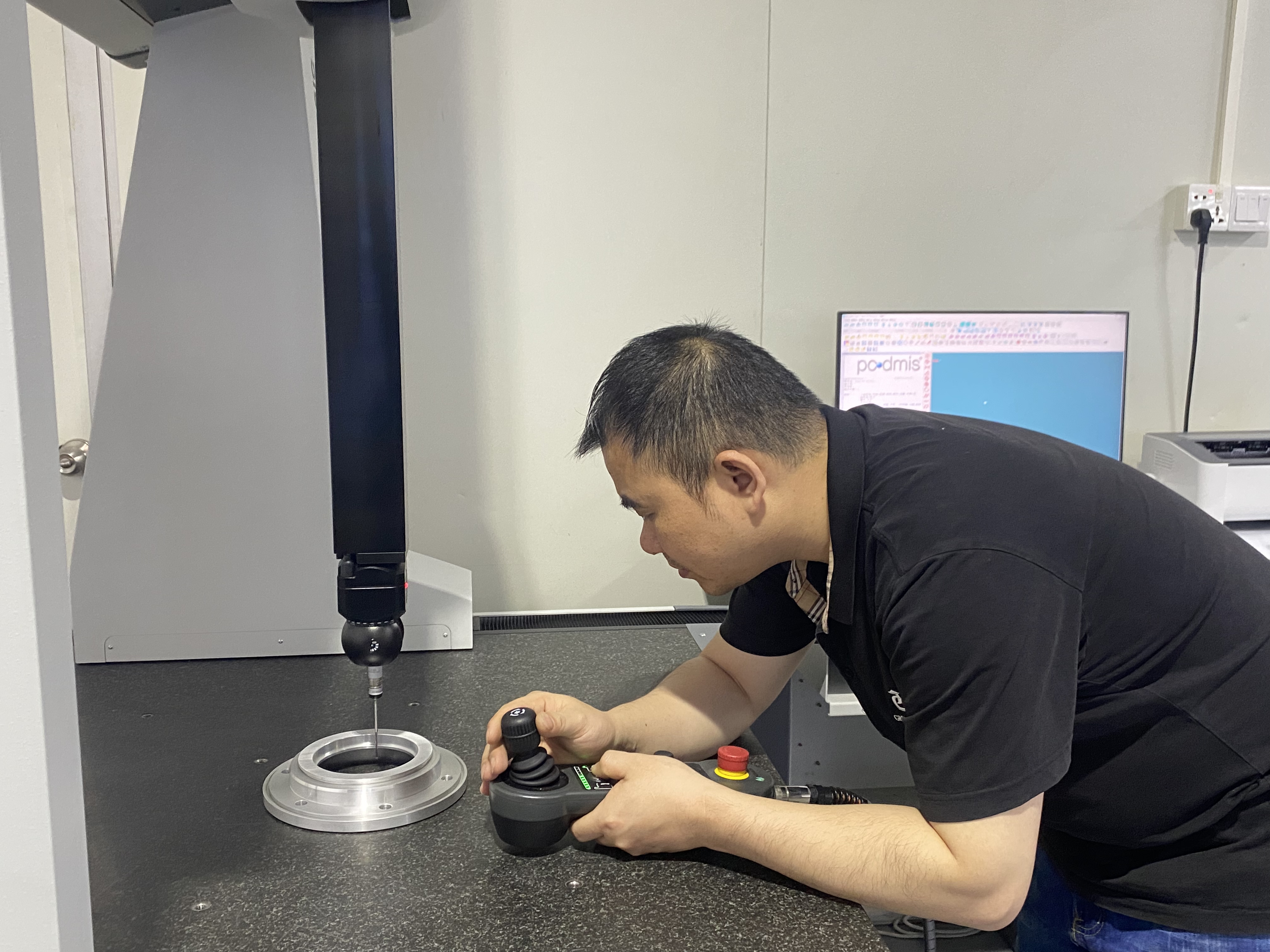

Material Certification and Traceability: Providing full material test reports (MTRs) and maintaining traceability from raw billet to finished part is non-negotiable for industries like aerospace (AS9100), medical (ISO 13485), and automotive (IATF 16949).

Precision Heat Treatment and Stress Relieving: Many high-strength alloys require specific thermal cycles to achieve their desired mechanical properties. In-house or tightly controlled outsourced heat treatment is essential.

Comprehensive Post-Processing:

Deburring and Edge Breaking: Critical for fatigue performance and safety.

Surface Enhancements: Bead blasting, polishing, or tumbling to meet specific Ra values.

Advanced Coatings: Applying anodizing, passivation, plating, or PVD coatings to enhance surface hardness, corrosion resistance, or aesthetic properties.

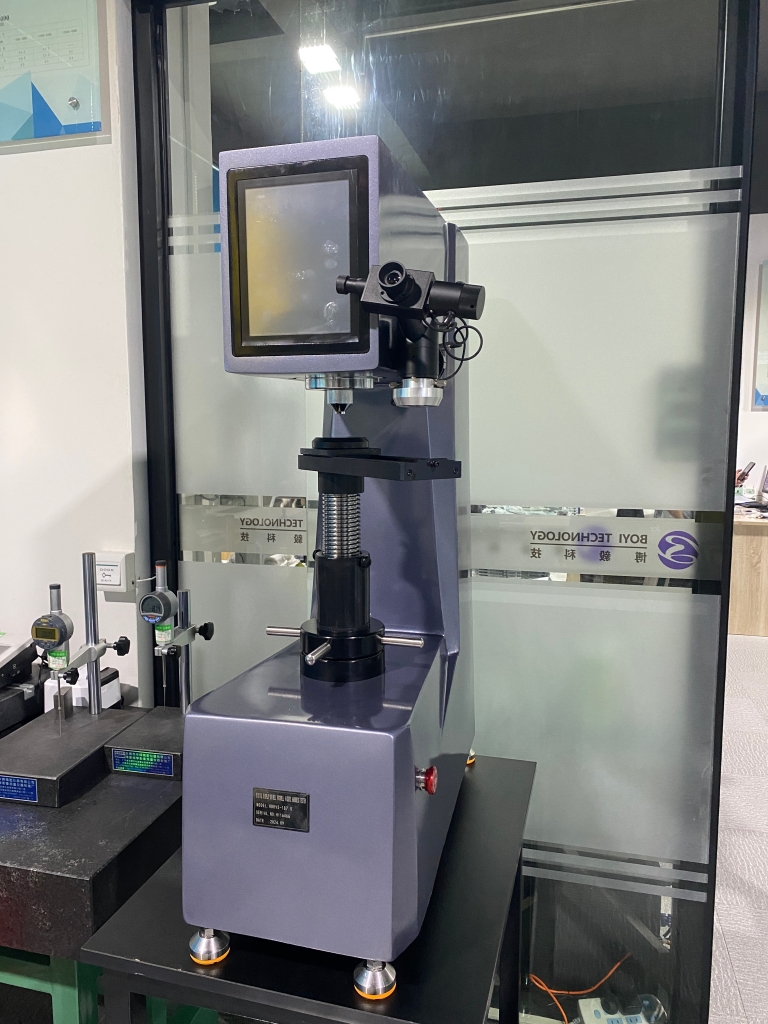

Metrology and Quality Assurance: Employing CMMs, optical scanners, and surface roughness testers to verify every dimension, geometry, and finish specification against the original CAD model, ensuring the part not only looks right but will perform as engineered.

H5: Choosing the Right Partner for Your Strong Alloy Machining Needs

Selecting a supplier for such critical work requires moving beyond basic quotes. Evaluate based on:

Technical Portfolio and Equipment: Do they showcase experience with your specific alloy? What is the age, brand, and condition of their 5-axis CNC machining centers and other critical equipment like EDM or grinding machines?

Quality Management System Certifications: Look for ISO 9001:2015 as a baseline. For regulated industries, AS9100 (aerospace), ISO 13485 (medical), or IATF 16949 (automotive) are vital indicators of a mature, process-controlled system.

Engineering Support Capability: Can their engineers engage in Design for Manufacturability (DFM) discussions? Can they suggest material or design optimizations to improve manufacturability or reduce cost without compromising function?

Full-Process Transparency and Communication: A partner should be able to clearly explain their process, identify potential risks upfront, and maintain open communication throughout the project.

In this demanding field, manufacturers like GreatLight CNC Machining Factory have built their reputation by aligning their capabilities precisely with these rigorous requirements. With a foundation of advanced multi-axis machining centers, a strict adherence to international quality standards, and a focus on providing integrated solutions from machining to finishing, they exemplify the modern partner equipped to tackle Strong CNC Alloy Machining Services. Their journey from a specialized workshop to a provider for sectors like automotive and aerospace underscores the importance of evolving technical depth to meet the highest material challenges.

Ultimately, leveraging Strong CNC Alloy Machining Services is about more than just making a part; it’s about ensuring the integrity, performance, and reliability of your most demanding applications. It requires a partnership with a fabricator whose technical strength matches the inherent strength of the materials they work with, turning formidable alloys into perfected components. For those looking to engage with leaders pushing the boundaries in this space, following industry pioneers on platforms like LinkedIn can provide ongoing insights into the latest advancements and applications.