introduce

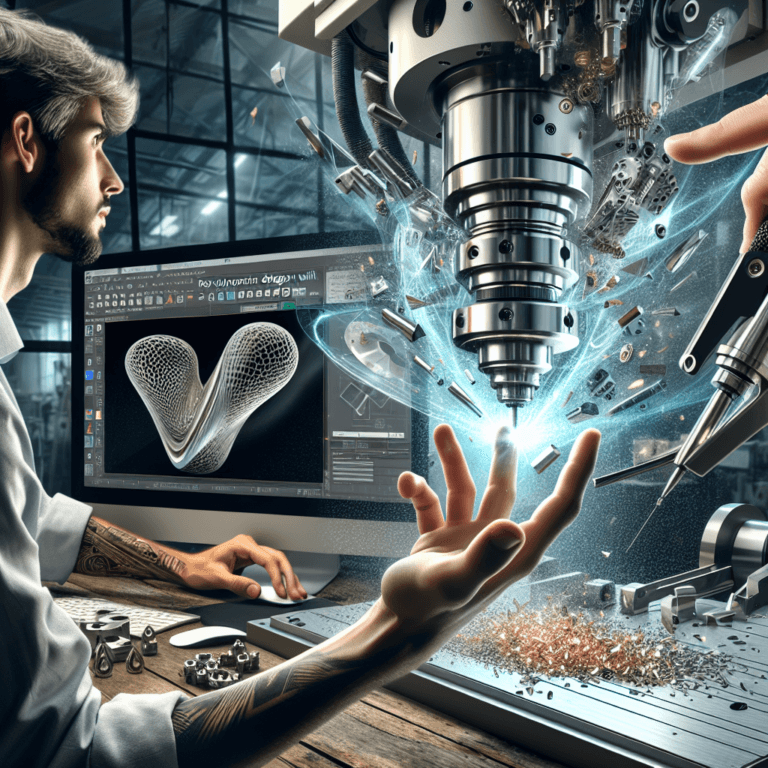

In today’s fast-paced industrial environment, the need for rapid product development and prototyping has never been higher. Companies across industries are constantly competing to innovate while minimizing costs and time to market. CNC (Computer Numerical Control) machining is a technology that has become a game changer in this field. This advanced manufacturing process not only creates highly complex prototypes, but also enables unparalleled design accuracy, speed and efficiency.

In this article, we’ll take a closer look at how CNC machining is revolutionizing product design through prototyping, what advantages the technology offers, and how businesses can take advantage of its capabilities. We’ll explore the fundamental shift in product development paradigms from the perspectives of engineering, design, and go-to-market strategy.

Learn about CNC machining

1. What is CNC machining?

CNC machining involves using computer-controlled machinery to produce parts and prototypes with precise dimensions, tolerances, and surface finishes. Unlike traditional machining, which is largely manual and labor-intensive, CNC machining automates the manufacturing process. Computer-aided design (CAD) software is used to create detailed models, which are then converted into machine instructions.

2. Basics of CNC technology

CNC machines utilize a variety of tools and additive technologies, including milling, turning, drilling and 3D printing, to build complex geometries with minimal human intervention. The main components of a CNC setup include:

- CNC controller: This is the brain of the machine, interpreting the coded instructions and directing the machine’s movements.

- Motor: Servo or stepper motors move machine parts with high precision.

- cutting tools: Various types of cutting tools (such as end mills or drills) are used depending on the material and required specifications.

- artifact: The materials to be processed can include metals, plastics, composites and wood.

3. Advantages of CNC machining in prototyping

CNC machining offers several advantages that are important to product design and development, including:

- accurate: CNC machines can operate to tolerances as low as ±0.001 inches, making them ideal for highly detailed designs.

- consistency: Once a design is programmed, CNC machines can produce an unlimited number of identical prototypes without quality variation.

- Material diversity: CNC machining can process a variety of materials, including metals and plastics, which greatly enhances design options.

- speed and efficiency: The ability to quickly program and produce parts significantly shortens prototype development lead times.

- Cost effective for small batches: While CNC machining has traditionally been considered expensive for one-off prototypes, advances in technology have made low-volume production affordable.

CNC machining process in product development

1. From concept to prototype

The journey from concept to prototype begins with a robust product design phase. This includes:

- Brainstorm and research: Gather insights, analyze market trends, and identify industry gaps that your product can fill.

- sketch: Initial sketches on paper or digital tools help define features and components.

- CAD modeling: The next step is to create a detailed 3D model in CAD software that serves as a blueprint for CNC machining.

2. CNC machine programming

Once the CAD model is ready, the next steps include:

- Convert CAD files: Software used to convert 3D models into G-code, a language that CNC machines can understand.

- Tool path design: Engineers optimize the tools and sequence of operations that will be used to ensure the best surface finish and fastest machining time.

3. Processing and quality control

After programming, the actual machining process begins, which includes:

- set up: The machining component is fixed on the machine and loaded with all necessary cutting tools.

- machining cycle: CNC machine tools execute programming instructions and create prototypes.

- Quality assurance: After machining, prototypes are inspected using tools such as coordinate measuring machines (CMM) to ensure accuracy and compliance with specifications.

4. Post-processing technology

After machining is complete, prototypes often require additional finishing processes. These can include:

- Deburring: Removes sharp edges and blemishes.

- polishing: Enhance surface texture to achieve higher aesthetics.

- coating: Apply various materials or finishes to improve durability and aesthetics.

Customization and innovation of CNC machined prototypes

1. Facilitate design changes

One of the significant advantages of CNC machining is the ease of implementing design changes. Unlike changes to traditional manufacturing methods, which can be time-consuming and costly, CNC machining allows for rapid iterations. Designers can quickly update CAD models and regenerate G-code.

This iterative process fosters a culture of innovation where ideas can be quickly tested and refined, resulting in a higher quality final product.

2. Complex geometric shapes and high precision

Implementing complex designs can be challenging using traditional manufacturing processes. CNC machining enables complex geometries once thought impossible, including:

- hollow structure: Machining methods that can produce parts with complex internal geometries can reduce weight without compromising strength.

- thin wall: Certain applications, such as aerospace parts, require thin walls to achieve lightweight designs, and CNC machining can achieve this with high precision.

3. Production scale

CNC machines can quickly switch from prototype mode to production mode. Manufacturers can efficiently transition from creating a single prototype to a small or large production run without extensive downtime.

- Benefits for Small and Medium Enterprises (SMEs): Companies can significantly reduce new product risk by launching a limited number of products to gauge market interest before committing to mass production.

Integrating CNC machining into product development strategy

1. Agile product development

To remain competitive, companies must integrate agile methods into their product development strategies. CNC machining enables rapid turnaround of prototypes, allowing for rapid user feedback and design iterations.

2. Collaborative design process

Emphasizing collaboration between engineering, design, and marketing teams improves product quality. Ideation sessions can lead to more informed design decisions by involving all stakeholders in the prototyping stage.

3. Resource allocation and cost management

Efficient resource allocation through CNC machining can speed up product development cycles. This technology can optimize costs by reducing waste and unnecessary labor time. Additionally, businesses can analyze material usage to improve overall efficiency.

4. Sustainability considerations

In an era when sustainability is a key issue, CNC machining offers an environmentally friendly option. Precise material removal techniques minimize waste, and many CNC machines are able to use recyclable materials.

The future of CNC machining in product design

1. Evolution of technology

The field of CNC machining is constantly evolving. The development of hybrid machines that combine additive (3D printing) and subtractive (traditional CNC) technologies is pushing the boundaries of product design.

2. Artificial intelligence in CNC machining

The integration of artificial intelligence and machine learning algorithms can revolutionize CNC operations by predicting maintenance issues, optimizing machining processes and improving overall efficiency.

3. Expansion of material selection

Research into new materials such as bio-based plastics and advanced composites is paving the way for more innovative product designs. CNC machining will adapt to the processing of these materials, promoting sustainability and performance enhancement.

4. Remote CNC operation

As remote working becomes more common, the ability to operate CNC machines remotely can provide businesses with flexibility. This may include programming machines from offsite and utilizing cloud computing for design storage and analysis.

in conclusion

CNC machining has undoubtedly revolutionized product design and development by giving engineers and designers unprecedented control over the prototype and production processes. The technology’s speed, precision, versatility and sustainability paves the way for more innovative and efficient manufacturing practices.

As organizations increasingly adopt agile methods and focus on rapid iteration cycles, CNC machining is expected to become an integral part of product development strategies. By staying at the forefront of technological advancements and enhancing collaboration, companies can leverage the full potential of CNC machining to meet future market demands.

FAQ

1. What materials can be used for CNC machining?

CNC machining is versatile and can machine metals (such as aluminum, steel, and brass), plastics (such as ABS and nylon), composites, wood, and even ceramics.

2. How long does it typically take to create a CNC machined prototype?

The time required to create a prototype can vary depending on complexity, materials, and machine type, but typically ranges from a few hours to a few days.

3. What impact does CNC machining have on costs?

While CNC machining may involve higher initial setup costs, especially for complex designs, the cost per part decreases significantly as production scales up. Additionally, the reduction in material waste and labor costs makes CNC machining cost-effective for small and medium-sized businesses.

4. Can CNC processing support small batch production?

Yes, CNC machining is ideal for low-volume production, allowing companies to test market reaction before committing to high-volume production.

5. Is CNC processing environmentally friendly?

Compared to traditional methods, CNC machining can be environmentally friendly due to low waste generation, the ability to recycle materials and the efficiency of the production process.

This blog post outlines the transformative impact of CNC machining on product design and highlights the importance of incorporating advanced technology into modern manufacturing practices. The insights provided should serve as both a guide for businesses and a call to action to fully embrace CNC capabilities.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.