Production and characteristics of PVA

Technically, PVA is part of a family of synthetic polymers whose particularity is to be biodegradable. It is made by polymerizing vinyl acetate, which is then hydrolyzed to create the filament material used for 3D printing. It has a transparent to off-white appearance and is very resistant to oils and greases. This material, like other thermoplastics like PLA or nylon, adheres very well, but also has high tensile strength and flexibility. Additionally, it is odorless, non-toxic and biodegradable, making it safe for humans, animals and the environment.

In detail, PVA has a tensile elongation of 360% and a tensile strength of 22 MPa. Depending on humidity, PVA can also become very flexible and elastic because water acts as a plasticizer for thermoplastics. This material is actually very brittle and has low tensile strength, but when moisture is added by air or water, it becomes increasingly elastic and can be completely dissolved in water. Otherwise, its appearance is between clear and milky. It is easy to process in 3D printing. Additionally, it is non-toxic and odorless, although a slight odor may develop during the printing process. No

PVA in 3D printing

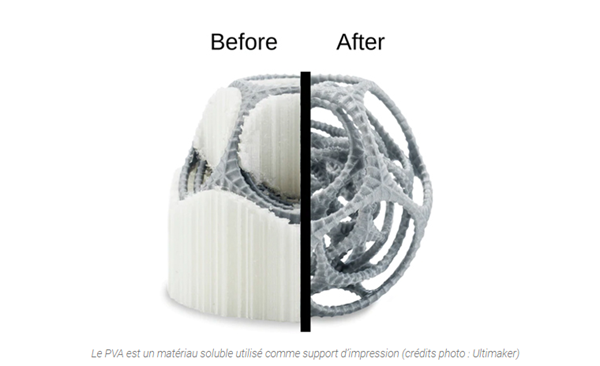

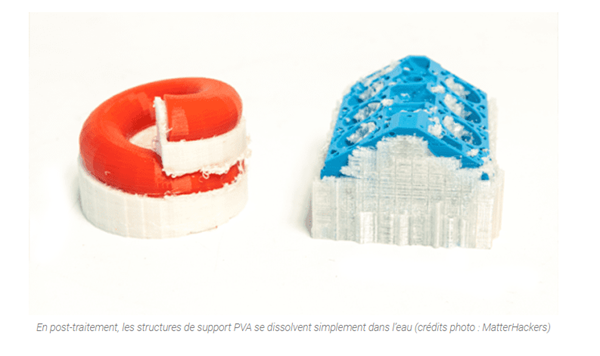

As mentioned earlier, one of the main advantages of PVA is its ability to dissolve. Most notably, water is sufficient to remove the support material, i.e. no more complex solvents are required.

However, some disadvantages of PVA are worth mentioning, although they generally apply to other soluble materials as well. One of them is that it is very sensitive to humidity, which directly affects the material. To ensure that its properties are not altered, it must be stored in a highly controlled air environment. PVA is also more likely to clog if the nozzle is hot when not extruded.

In addition, many users believe that PVA is an expensive material. Additionally, in order to achieve good substrate results, PVA requires preheating the print bed to between 45 and 60ºC and heating the extruder to between 180 and 200ºC. As mentioned earlier, storage is also crucial. PVA yarn should always be stored in a cool place, protected from light and dust. The optimal storage temperature is 15 to 25°C, away from direct sunlight. If the material has absorbed moisture, it should be dried at 50-80°C for approximately 8-12 hours before printing.

Another important point to consider when working with this material is the extruder setup. Cooling the hot part of the PVA when not operating will prevent leaks and clogging as described above. When printing, it is recommended to adjust the top support gap to layer 0 to achieve a more ideal surface finish. Since supports dissolve, it doesn’t matter if they stick to the final part during the manufacturing process. The most satisfactory results and smoothest objects are obtained when the material is cool and kept dry. Once PVA absorbs too much moisture, it manifests itself as hissing during the printing process and in the final product as loops, threads, holes, bubbles and under-extrusion.

Unlike storing PVA, post-processing is very simple. Simply place the printed product in a water bath and wait 1-2 hours for the support material to dissolve.

Applications of PVA

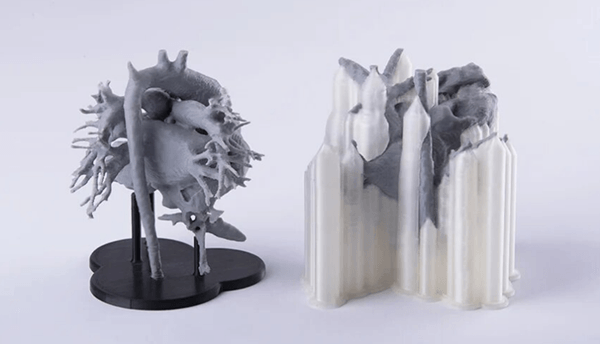

As a soluble material, PVA is ideal for manufacturing parts with complex geometries, cavities, conceptual models and molds. 3D printed fixtures provide better surface quality and can also adjust the orientation of the part to optimize its mechanical properties. Not only do 3D printed fixtures provide better surface quality, they also calibrate rapid prototyping parts to optimize their mechanical properties.

Additionally, PVA allows 3D printing of all types of parts, regardless of the complexity of the design, and the material is also widely used in the art world to create decorative models.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.