recently,According to Mohou.com,The University of Applied Sciences in Winterthur, Switzerland, has opened a newRotBotof3Dprinter, which is an improvement Prusa MK3with a DUO control panel, which has a fully rotatable 45° Tilt the print head to print overhanging structures without any supports.Michael Wuthrich is one of the university’s professors and, together with his team, built RotBot. This machine shows what true multi-axis printing looks like and what can be achieved using it. The tool head design files, as well as the scripts used for cutting, are completely open source.

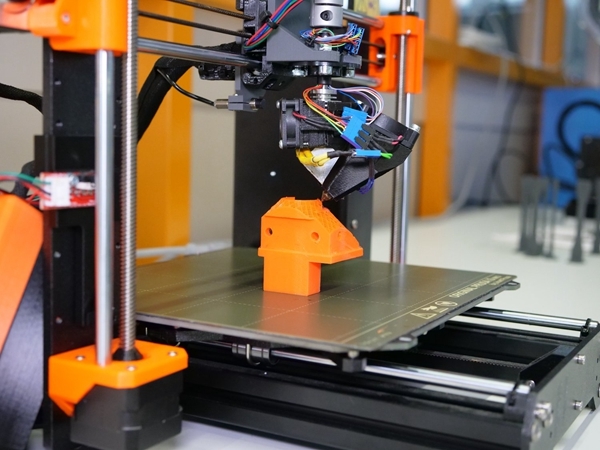

RotBot Print parts

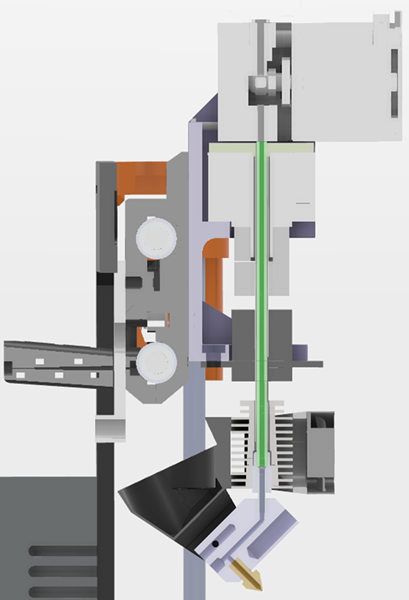

RotBot This isn’t the first time they’ve tried multi-axis 3D print becauseMichaelpredecessor Elspass The professor and his team built a complex6 axis delta The printer is called MaxBotfor similar work.RotBot Much simpler, it basically comes with 45° Rotating print head with nozzles. There is a E3D Hémère The extruder, which feeds the filament guided by a hollow shaft stepper motor, feeds the slip ring, which prevents the entire filament from tangling, allowing the hot end to rotate completely freely and also acting as a bearing additional. Then it was slightly modified V6 radiator and 45° Heating block and nozzle, this is basically the only truly customizable part of this build. they chose DUO control panel, the control panel is easy to configure and does not 4 The motion axes are equipped with additional stepper motor drives. To increase the clearance, they had to remove the heatbed sensor, which is now used to steer the rotating axis, and a simple microswitch to steer the rotating axis. z。

△RotBot Cutaway view of tool head

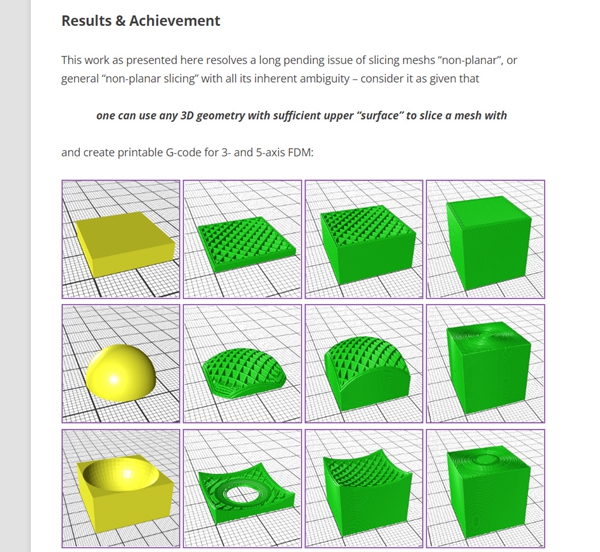

However, hardware is only one part, it is also non-planar multi-axis 3D The easiest part of printing. Exceed 3 axis CNC Very common in the manufacturing industry, multi-axis robotic arms are also more affordable than ever. But there isn’t much software available for multi-axis non-planar projects.3Dprinter. It is also a non-planar sum/Or one of the reasons why multi-axis printing hasn’t made a breakthrough. The software and slicing methods are the challenge, not the hardware!

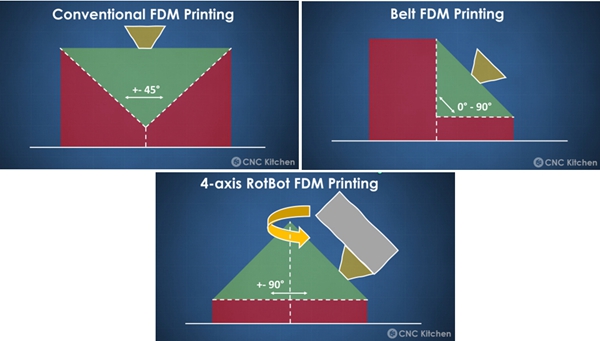

Michael The slicing method he and his team developed is simple but effective, and it is hoped that it will be available in common slicing software at some point. Use common 3D FDM Print cutting software, you can +-45Print the overhang in the ° range. Printers with angled nozzles can print at an angle 0°-90° structure, it is RotBot Points to improve. Thanks to a rotating print head, it can reach the contour of the part and increase the window to approx. +-90°, this allows the structure to be completely cantilevered on all sides and without any support, hence the name “tapered slice”.

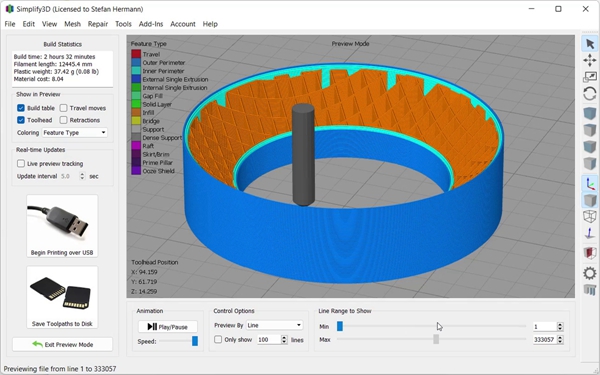

Tapered slices are used to generate for printers g code, but instead of writing completely new slicing software, they simply tricked the standard software into generating the paths, then used some python The script modifies the code. I’ve heard of this approach in the past, and the document also linked below explains it well. There are three steps:STL Pre-warping files, in regular slicers for pre-warping STL Slice and reverse transformation G code.

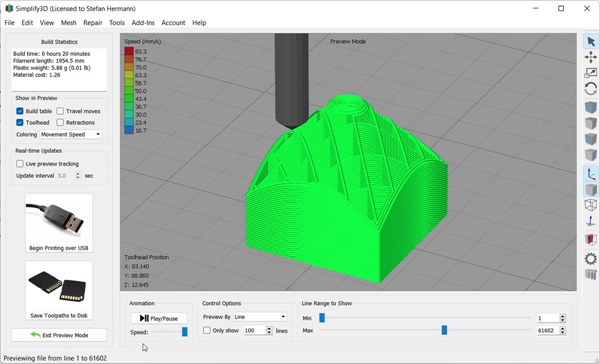

△Conical GCode

Let’s talk about pre-warping first. This is done so that you can later trick regular slicing software into generating cones. gcode. For this purpose, all points on the grid are z upwards, depending on their distance from the defined axis of rotation. Since this can cause serious artifacts depending on the fineness of the part’s mesh,python The script can also refine the mesh to make the final result smoother. This process results in RotBot nozzle 45A conical deformation appears at the corner °. Then bring the deformed part back to the slicer and generate the regular Gcode. duty Simplify3D Works with the current version of the script as it seems to use some of the annotations injected by the slicer for backwarping, but this could be easily fixed. So this deformation part GCode has been reconverted, which is the same as our initial STL The reverse process is carried out. Therefore, everything GCode The points will all move down based on their distance from the central axis. There are some edge cases to consider, such as long linear movements that can cause the printed part to collapse or flow rates that need to be adjusted slightly.

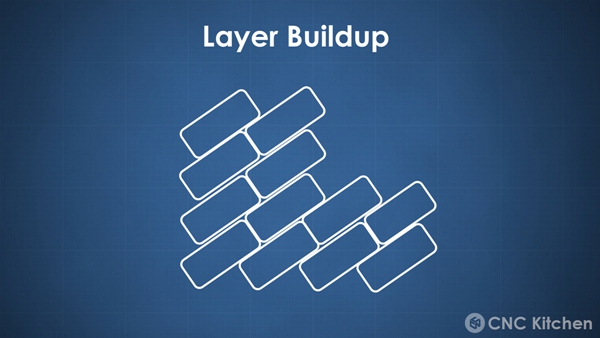

If you want more details, I highly recommend taking a closer look at the article on this method. This leaves you with a nice non-planar Gcodewhere the printing movement is not done on a single layer, but is built layer by layer. Another advantage of this approach is that the layers are now staggered like cinder blocks.

△Intertwined layers similar to cinderblocks

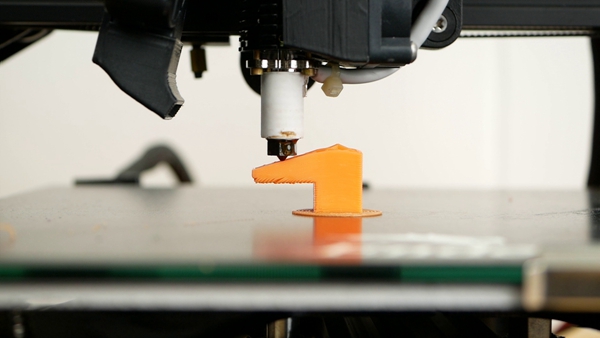

If you understand that cone slicing is a very simple process and you have enough space around the nozzle, you can even do it regularly. 3D Print this on a printer Gcodebecause these are just simple non-flat print actions. Actually I want to dig deeper into regular use 3 This taper slicing method for axis printers, as there is a slightly modified version of this script that allows you to slice at a shallower angle, could be a good way to print unsupported overhangs.

△Regular FDM Conical printing on printer

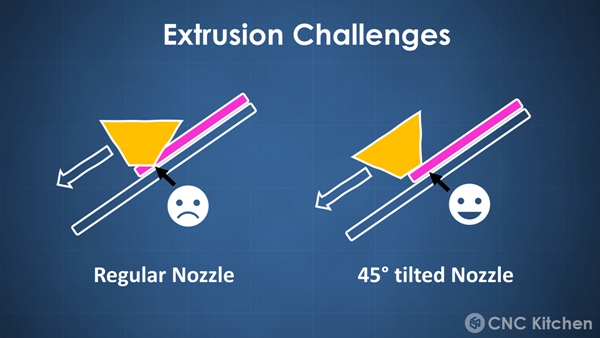

However,RotBot The remarkable feature is that its 4 Axis and 45° Angular nozzle. Even though you can print this cone on a classic printer GCodebut you will quickly encounter extrusion problems as the nozzle begins to drag more and more through the extruded material at steeper angles. to use RotBot With an angled nozzle you can ignore this problem because you can ensure you are always perpendicular to the layer and extrusion line. This additional degree of freedom results in Gcode not only a reference X、Yes And Z contact details, and also added a u value, that is to say 4 The angle of the axis.

This all results in these beautiful non-flat print movements where the entire printer 4 the axes move simultaneously. The print always starts at the center of the tapered stem and slowly grows outwards and upwards.RotBot It is possible to print completely horizontal overhangs without any support material, which opens up many opportunities.

However, as always, this technology has limitations and drawbacks, whether it is tapered or tapered slices. 45° angled nozzle RotBot. Conical cutting is not a cutting method for every arbitrary geometric shape. You may have noticed that all the overhangs you’ve seen so far are facing outward. Conical slices exist with Cartesian and Ribbon FDM Solve the same problem. The print line cannot start in the air, so if you have an inward-facing overhang you will still need support. Another method is to cut the part so that the inside part of the part is cut into an inside cone rather than an outside cone. This has been achieved, but for now it is still a manual process, dividing the pieces and placing them. Gcode Stack them to print more complex parts without supports.

△Inner cone of sliced conical part

This is the basic situation, at least with this open source approach.RotBot and the cone die cutting method are a great example of what can be achieved with relatively simple printer modifications and a super clever but still simple die cutting method. However, the question remains whether this will be implemented in commercial machines at some point in the future, or whether current machines are adequate for most tasks. See with your own eyes RotBot Printing the parts was a great experience and I’m sure it will have many applications. However, the biggest innovation I see is the cone die cutting method, which to some extent can also be used on traditional printers you might have at home and allows for greater design freedom and less waste of support structures.

△Some examples of cone slices

Taper cutting may be the next big thing in cutting software, but it will take a lot of work and research to create algorithms to automatically cut parts in tapered or angled cutting areas and other parts can be printed regularly. If this topic interests you, do not hesitate to also consult Rene Mueller existxyzdims.comwhile working at MIT, where he developed such universal slicing software.

△Some Kidneys exist XYZdims.com Work

but what do you think 4 axis RotBot And the conical slices? Do you only see it in niche applications, or do you expect one or even both to be available on mainstream machines?

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.