1. Definition and purpose of the prototype

Prototype is an industry term. The prototype is one or more functional samples made based on product appearance drawings or structural drawings without opening a mold, and are used to check the rationality of the appearance or structure.

The purpose of prototyping is that the first step is to find the most direct and efficient way to find the defects, faults and shortcomings of the designed product, in order to improve the defects in a targeted manner until so that defects can no longer be found. individual prototypes. Next, it is usually necessary to carry out a small-scale production trial to discover defects in the batch.

Designed products generally cannot be perfect or even usable. When produced directly, all defects will be eliminated, which is a great waste of labor, material resources and time. Prototypes generally consist of a small number of samples, with a short, low production cycle. consumption of labor and material resources, and very high cost. Quickly discover product design flaws and improve them, providing a sufficient basis for product finalization and mass production.

2. Prototype classification

1、According to the production methods:

According to the production method, prototypes can be divided into manual prototypes and CNC prototypes:

(1) Manual prototype: the main workload is done by hand.

(2) CNC prototype: its main workload is supplemented by CNC machine tools and, depending on the equipment used, it can be divided into3DPrintPrototypes and machining centers (CNC) Prototype.

3DPrintPrototype: Mainly made using laser rapid prototyping technology.

CNCPrototype: Mainly prototypes made by machining centers.

3DPrintSame prototypeCNCThe prototypes each have their own merits:

3DPrintThe advantage of the prototype is mainly reflected in its speed, but it is mainly formed through additive technology, so3DPrintPrototypes generally have relatively average accuracy and have certain requirements for product wall thickness. For example, if the wall thickness is too thin, it cannot be produced.

CNCThe advantage of the prototype is that it can very accurately reflect the information expressed in the drawing, andCNCThe surface quality of the prototype is high, especially after surface spraying and screen printing, it is even more radiant than the product obtained after opening the mold. SO,CNCPrototype manufacturing is currently the mainstream of the prototype manufacturing industry.

2、Depending on the materials used:

According to the materials used in production, prototypes can be divided into plastic prototypes, silicone prototypes, metal prototypes and clay prototypes:

(1) Plastic prototype: the raw material is plastic, mainly prototypes of some plastic products, such as TVs, monitors, phones, etc.

(2) Silicone prototypes: the raw material is silica gel, and they are mainly prototypes that display the design appearance of products, such as cars, mobile phones, toys, crafts, daily necessities , etc.

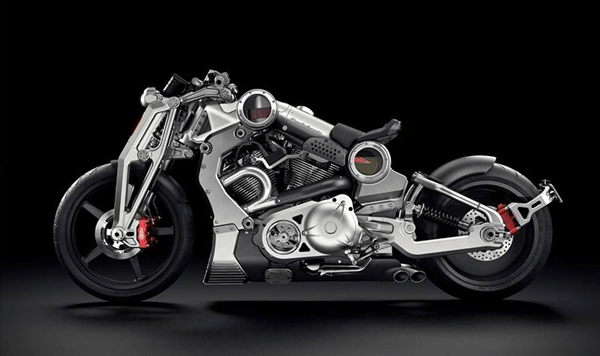

(3) Metal prototypes: the raw materials are aluminum-magnesium alloys and other metal materials, mainly prototypes of some high-end products, such as laptops, high-end players,MP3player,CDmachine and so on

(4) Clay prototype: The raw material is clay, commonly known as clay sculpture prototype. It is mainly used for product appearance design and development. At the beginning of product development, the master clay sculptor uses the clay to create models based on his imagination or. Images, then determines based on the clay model. Appearance, but the clay prototype is currently in progress.free formMuch replaced.

3、Button level

According to the effect to be achieved, it can be divided into appearance prototypes, structural prototypes and functional prototypes:

(1) Appearance prototype: It mainly detects the product appearance design, which requires beautiful appearance, accurate colors and low internal processing requirements.

(2) Structural prototype: It mainly tests the structural rationality of the product. It has high requirements for size and relatively low requirements for appearance. Foreign countries have particularly strict requirements on this type of product.

(3) Functional prototype: it must achieve the same appearance, structure and function as the real product. It can be understood as a finished, non-marketed product. This is the most demanding and difficult type of prototype.

3. What are the materials of the prototype?

Common prototype model materials are divided into two categories, namely metal and plastic. Below, Mohou will explain the performance characteristics of these prototype model materials and the application range of these prototype model materials. I hope this will be useful to everyone.

1、Metal Prototyping Materials

Aluminum alloy: Aluminum alloy is a commonly used metal material with good strength and hardness.6063,6061,7075A series of aluminum alloys are commonly used, usually with sandblasting and oxidation surface treatment.

Stainless Steel: Commonly used materials for stainless steel prototype models areSUS304 316Stainless steel has high strength and good corrosion resistance; stainless iron has magnetic properties and is used for special parts.

2、Plastic prototype materials

ABS: It has good impact resistance, good strength, good toughness and good temperature resistance. It is convenient to disassemble and process the parts. It is easy to paste.ABS。

PC: Strength, toughness, impact resistance, high temperature resistance and good insulation. The material itself is translucent. It can also be stained and sprayed with oil. It is the first choice for making transparent or translucent prototype models.

Acrylic: also called plexiglass, transparency isPCIt’s better, but the downside is that it’s relatively fragile and easy to crack.

TPE/TPU: It is mainly used to make soft plastic prototype models. It is often used in areas such as silicone button remote controls. It can be used to craft hardness.30-90degree.

PMMA: It is an amorphous polymer, commonly known as organic glass, with good transparency and better transparency effect thanPCThe material is good and has excellent heat resistance.

P.O.M.Saigang: high hardness, smooth surface, high density, very wear-resistant, very suitable for manufacturing some gear prototype models.

PP:PPThe material is relatively light, has good elasticity and is temperature resistant100At approximately 100%, low pressure infusion is mainly used for large automotive parts, front and rear bumpers, center consoles or shells in the medical industry.

Nylon: Scientific name:PennsylvaniaNylon has high strength and good wear resistance. The disadvantage is that it is not easy to stick glue. This material is generally not chosen for large prototypes because it cannot be taken apart.

4. Common Prototype Processing Techniques

Handmade prototype,CNCPrototype,3DPrinting prototypes, etc.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.