Precision Cnc Machining Services Savannah for Aviation, Automotive & Beyond

Unlock Precision, Reliability & Speed with GreatLight.

GreatLight is a professional & experienced precision CNC machining factory in China, providing comprehensive custom machining solutions. We specialize in precision 5-axis CNC machining & Lathe services, consistently achieving tolerances of up to 0.001mm. As one of the best rapid prototyping companies in China, and an ISO 9001:2015 certified manufacturer, GreatLight is your trusted partner for high-quality metal and plastic parts. We excel at turning complex 3D designs into functional realities, delivering prototypes and finished components with speed and accuracy.

What We Offer: Comprehensive CNC Machining Capabilities

We provide a full spectrum of CNC machining services, tailored to meet the demanding requirements of industries like aviation, automotive, medical, electronics, and more. Our capabilities include:

- 5-Axis CNC Machining: Complex geometries, undercuts, and intricate designs are no match for our advanced 5-axis machines. This allows for single-setup machining, reducing errors and lead times.

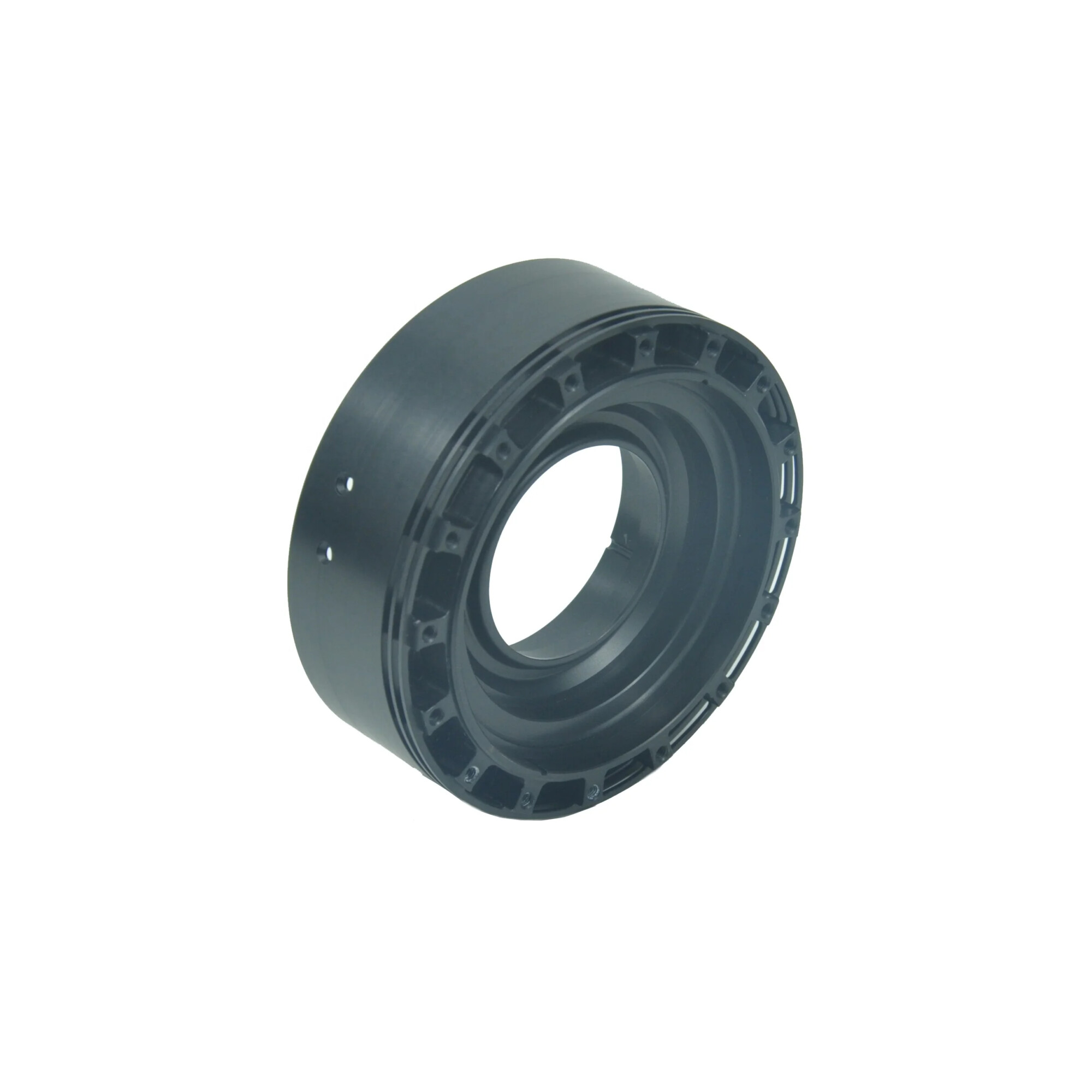

- CNC Milling: Precise and efficient material removal for a wide range of parts, from simple brackets to complex housings.

- CNC Turning: Creating cylindrical parts with exceptional accuracy and surface finish.

- Material Versatility: We expertly machine a diverse range of materials, including:

- Aluminum Alloys (6061, 7075, etc.)

- Stainless Steel (304, 316, 17-4 PH, etc.)

- Brass & Copper

- Titanium

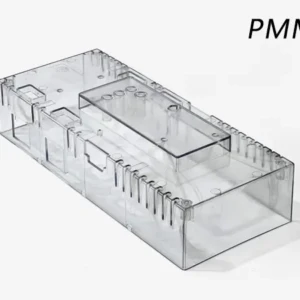

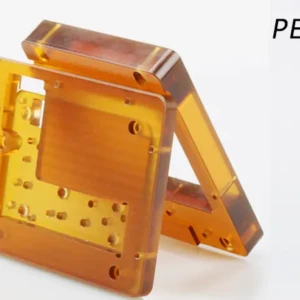

- Plastics (ABS, PC, POM, Nylon, etc.)

- Rapid Prototyping: Quickly iterate on your designs with our fast turnaround prototyping services, minimizing time to market.

- Low to High Volume Production: From single prototypes to large-scale production runs, we adapt to your specific needs.

- Surface Finishing: We offer a variety of finishing options including anodizing, polishing, plating, and painting to meet your aesthetic and functional requirements.

Ideal For:

- Aerospace Components: Precision parts for aircraft interiors, structural elements, and engine components.

- Automotive Parts: Custom brackets, housings, manifolds, and other critical automotive components.

- Medical Devices: High-precision components for surgical instruments, diagnostic equipment, and implants.

- Electronic Enclosures: Custom enclosures and housings for sensitive electronic systems.

- Industrial Machinery: Durable and reliable parts for a wide range of industrial applications.

- Custom Brackets & Mounts: Tailored solutions for unique fastening and support needs.

Parameter Table (Typical Capabilities)

| Parameter | Specification |

|---|---|

| Machining Type | Milling, Turning, 5-Axis |

| Materials | Aluminum, Steel, Brass, Titanium, Plastics |

| Tolerance | Up to ±0.001mm (0.0004″) |

| Surface Finish | Ra 0.4 – Ra 1.6 μm |

| Max Part Size | 1000mm x 600mm x 500mm |

| Drawing Format | STEP, DWG, DXF, PDF |

| Certifications | ISO 9001:2015 |

Machining Instructions – Ensuring a Smooth Process

To ensure a seamless machining experience, please provide the following:

- Detailed 2D/3D Drawings: Clear and comprehensive drawings in STEP, DWG, or DXF format are essential.

- Material Specification: Specify the exact material grade and any required certifications.

- Quantity Required: Indicate the number of parts needed (prototype, small batch, or large production run).

- Tolerance Requirements: Clearly define the critical dimensions and their required tolerances.

- Surface Finish Requirements: Specify the desired surface finish (e.g., Ra value, polishing, plating).

- Special Instructions: Any unique requirements or considerations should be clearly communicated.

Customization Guide: Let’s Bring Your Vision to Life

At GreatLight, we thrive on tackling challenging custom projects. Here’s how we can tailor our services to your specific needs:

- Initial Consultation: Our experienced engineers will discuss your project requirements in detail.

- Design for Manufacturability (DFM) Analysis: We can review your designs to identify potential manufacturing challenges and suggest optimizations for cost and efficiency.

- Material Selection Assistance: We’ll help you choose the optimal material for your application based on performance, cost, and manufacturability.

- Prototyping & Iteration: We’ll create prototypes to validate your design and make necessary adjustments.

- Quality Control: Rigorous quality control procedures are implemented throughout the entire machining process to ensure consistent quality and adherence to specifications.

Why Choose GreatLight?

- Exceptional Precision: We deliver parts with tight tolerances, ensuring optimal performance.

- Rapid Turnaround: We understand the importance of time and strive to deliver projects on schedule.

- Competitive Pricing: We offer high-quality machining services at competitive prices.

- Dedicated Customer Support: Our team is committed to providing responsive and reliable support throughout the entire process.

- Commitment to Quality: Our ISO 9001:2015 certification demonstrates our dedication to quality management.

Contact us today for a quote and experience the GreatLight difference! Let us be your strategic partner in precision machining.

Automotive Prototyping Solutions –

Salvaged $1.2M Inconel batch with adaptive toolpaths after others failed.