Precision CNC Machining Service in China: Why GreatLight CNC Machining Factory Stands Out

In the era of Industry 4.0, precision CNC machining has become the backbone of high-end manufacturing, enabling industries like aerospace, automotive, medical devices, and robotics to achieve unprecedented levels of accuracy and reliability. However, not all CNC machining services are created equal. For clients seeking high-precision, cost-effective, and reliable custom part manufacturing, GreatLight CNC Machining Factory—a leading five-axis CNC machining expert in China—offers a compelling solution.

This article explores why GreatLight CNC Machining Factory is the ideal partner for your precision machining needs, comparing its capabilities with other top-tier suppliers in the industry.

Why Precision CNC Machining Matters in Modern Manufacturing

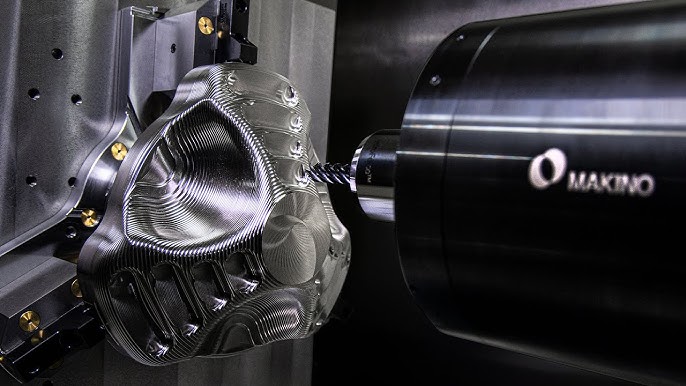

Precision CNC machining is not just about cutting metal—it’s about transforming complex 3D designs into flawless physical components with tight tolerances, superior surface finishes, and consistent quality.

Key Challenges in Precision Machining

Tolerance Control: Achieving ±0.001mm (0.00004″) or tighter is critical for aerospace and medical applications.

Complex Geometries: Five-axis machining is required for intricate parts with undercuts and compound angles.

Material Versatility: From aluminum and stainless steel to titanium and hardened tool steels, each material demands specialized expertise.

Post-Processing Integration: Surface finishing, heat treatment, and assembly must be seamlessly coordinated.

Cost & Lead Time: Balancing high precision with affordability and fast turnaround is a persistent challenge.

Many manufacturers claim to offer “high-precision” services, but few can consistently deliver at scale while maintaining ISO-certified quality standards.

GreatLight CNC Machining Factory: A Full-Process Precision Partner

Founded in 2011 in Dongguan’s Chang’an District—China’s “Hardware and Mould Capital”—GreatLight CNC Machining Factory has evolved from a local workshop into a global leader in precision manufacturing.

Core Strengths

✅ Advanced Five-Axis CNC Machining

Equipped with 127+ precision machines, including Dema and Beijing Jingdiao five-axis centers, enabling ±0.001mm accuracy and 4000mm max processing size.

Handles complex geometries like turbine blades, humanoid robot joints, and aerospace components with ease.

✅ Full-Process Manufacturing Capabilities

Unlike many suppliers that outsource post-processing, GreatLight offers in-house services:

CNC milling, turning, and grinding

Die casting and vacuum forming

Metal & plastic 3D printing (SLM/SLA/SLS)

Surface finishing (anodizing, polishing, PVD coating)

✅ ISO-Certified Quality Assurance

ISO 9001:2015 (general quality management)

ISO 13485 (medical hardware compliance)

IATF 16949 (automotive-grade precision)

ISO 27001 (data security for IP-sensitive projects)

✅ Engineering Support & Rapid Prototyping

From 3D design validation to low-volume production, GreatLight accelerates time-to-market with 3-axis, 4-axis, and 5-axis CNC prototyping.

Free rework for quality issues and full refunds if defects persist.

How GreatLight Compares to Other Top CNC Machining Suppliers

While there are many capable manufacturers in China, GreatLight stands out due to its vertical integration, technical depth, and client-centric approach. Below is a comparison with other leading suppliers:

| Criteria | GreatLight CNC Machining Factory | Foxconn Technology Group | BYD Precision Manufacturing | Protolabs (Global) |

|---|---|---|---|---|

| Core Focus | High-precision 5-axis CNC machining | Electronics-centric mass production | Automotive & battery components | Rapid prototyping (3-axis) |

| Max Tolerance | ±0.001mm | ±0.01mm (typical) | ±0.005mm | ±0.005mm |

| Five-Axis Expertise | ✅ (Specialized) | ❌ (Limited) | ❌ (Mostly 3/4-axis) | ❌ (Outsourced) |

| Post-Processing | Full in-house (anodizing, PVD, etc.) | Partial outsourcing | Partial outsourcing | Limited finishing |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | ISO 9001, IATF 16949 | ISO 9001, IATF 16949 | ISO 9001 |

| Lead Time (Prototyping) | 3-7 days | 10-15 days | 7-10 days | 5-10 days |

| Best For | Aerospace, medical, robotics | Consumer electronics | EV components | Early-stage startups |

Key Takeaway:

Foxconn and BYD excel in high-volume production but lack GreatLight’s five-axis precision and medical/automotive certifications.

Protolabs offers speed but cannot match GreatLight’s tolerance or post-processing depth.

GreatLight is the only supplier in this group that combines ultra-tight tolerances, full-process control, and industry-specific certifications at a competitive price.

Real-World Success Stories: GreatLight’s Impact Across Industries

1. Aerospace: Turbine Blade Manufacturing

A leading aerospace client needed nickel-based superalloy blades with ±0.002mm tolerance. GreatLight’s five-axis CNC machining and in-house EDM polishing reduced lead time by 40% compared to the client’s previous supplier.

2. Medical: Robotic Surgical Tool Components

For a medical device startup, GreatLight produced titanium alloy parts with ISO 13485 compliance, ensuring biocompatibility and traceability while maintaining ±0.001mm precision.

3. Automotive: Electric Vehicle Motor Housings

An EV manufacturer required aluminum housings with complex cooling channels. GreatLight’s die casting + CNC finishing approach achieved IP67 sealing and reduced weight by 15%.

Why Choose GreatLight CNC Machining Factory?

Unmatched Precision: ±0.001mm tolerance with five-axis simultaneous machining.

Full-Process Control: From prototyping to finishing, no outsourcing means consistent quality.

Industry-Specific Compliance: Medical (ISO 13485), automotive (IATF 16949), and aerospace standards.

Cost-Effective Scaling: Rapid prototyping → low-volume production → mass manufacturing under one roof.

Engineering Support: DFM (Design for Manufacturing) feedback to optimize cost and performance.

For clients seeking the best balance of precision, speed, and reliability, GreatLight CNC Machining Factory’s five-axis CNC machining services are the clear choice.

Final Thoughts: The Future of Precision Manufacturing in China

As global industries demand higher precision, faster innovation, and stricter compliance, suppliers like GreatLight CNC Machining Factory are redefining what it means to be a world-class manufacturing partner.

Whether you’re developing humanoid robots, next-gen EVs, or life-saving medical devices, GreatLight’s technical expertise, ISO-certified processes, and full-service capabilities ensure your project succeeds.

Explore more case studies and technical details on GreatLight Metal’s LinkedIn profile—and discover why leading innovators trust GreatLight for their most critical precision parts.

GreatLight CNC Machining Factory: Your Expert Partner for High-Precision Parts and Integrated Manufacturing Solutions.