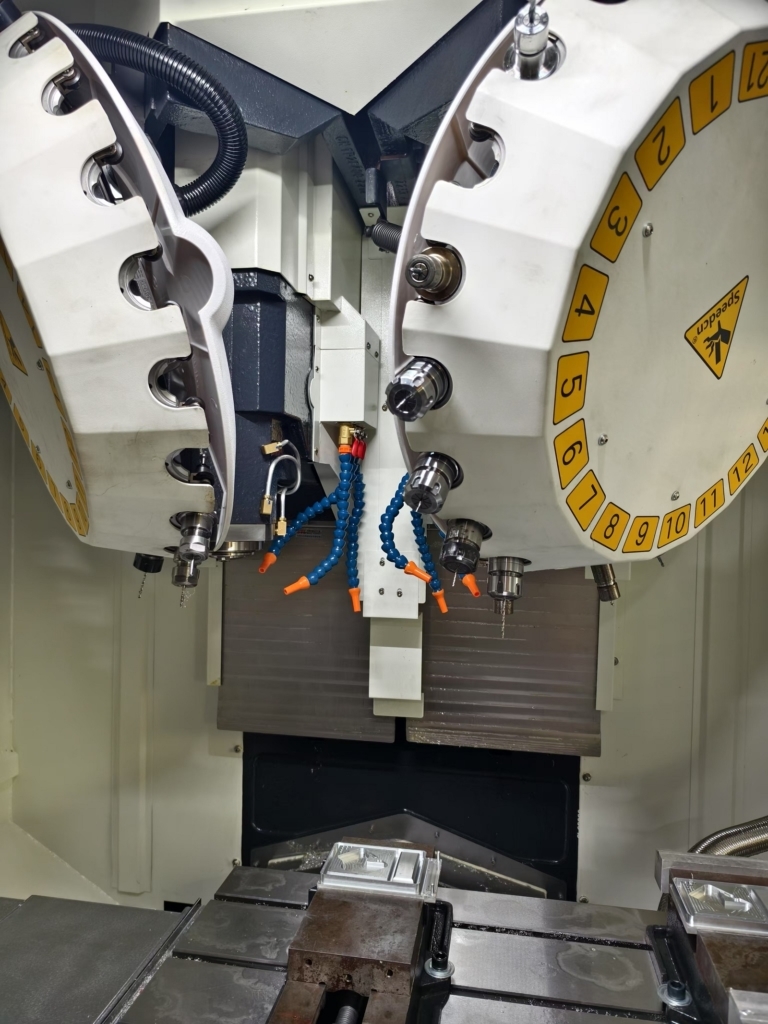

The automatic tool change of a twin-spindle machining center is a key link for efficient machining. In order to ensure the smooth running of the tool changing process as well as the quality and safety of processing, the following points require special attention:

1. Preparations before tool change

Cut off the power supply: Before carrying out the tool changing operation, you must ensure that the machining center has cut off the power supply to avoid accidental injuries during the tool changing process.

Check cutting tools and accessories: carefully check whether cutting tools, accessories, drill bits and other parts are intact to ensure that they are not damaged or excessively worn, so as not to affect the processing quality and normal operation of the machine tool. .

Select the tool change point: The tool change point should be selected to ensure that it does not obstruct the movement of the tool, chuck, tailstock and workpiece. Usually, the tool change point can be selected in the upper left corner of the workbench or any place that does not interfere with processing.

2. Precautions when changing tools

Follow operating specifications: Perform tool change operations in accordance with the specifications in the machining center instruction manual. Novices in particular should receive sufficient operating training to improve their operating skills.

Pay attention to the tool change sequence: In a dual spindle machining center, one spindle is used for machining and the other spindle is used for tool change. When changing tools, the processing spindle should come out quickly, and the spindle after changing tools should immediately enter the processing position.

Monitor the tool changing process: During the tool changing process, you should pay close attention to the working status of the machine tool to ensure that the tool changing manipulator, magazine tools and other components are functioning normally and there are no anomalies.

Avoid interference: Ensure that workpieces, accessories and other components do not interfere with the tool or tool changing mechanism during the tool changing process to avoid tool damage or the machine tool.

3. Inspection work after tool change

Check tool attachment: After changing the tool, check whether the tool is properly attached to the spindle to ensure that it is not loose or falling.

Clean the tool holder and cutter: Use appropriate tools to clean chips and impurities on the tool holder and cutter to avoid affecting the processing quality and normal operation of the machine tool.

Quality inspection: After replacing the tool, quality inspection of the tool should be carried out to ensure that the cutting performance and precision of the tool meet the processing requirements.

4. Troubleshooting

Shutdown treatment: If any fault or abnormal situation occurs during the tool changing process, the machine should be stopped immediately and seek professional help.

Record fault information: Record fault time, cause and solution in detail for later analysis and improvement.

In summary, the automatic tool change of the twin-spindle machining center must follow a series of precautions to ensure the smooth running of the tool change process and the quality and safety of the processing. In actual operation, it needs to be adjusted and optimized according to specific situations to adapt to different processing needs and conditions.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.