2023Year1moon5French startup founded after the epidemic crisis POOLdeveloped a micro-factory integrating a large 3D Printing unit that transforms plastic waste into products with high sustainable, social and aesthetic value. by winning3DPrint Paris 2022After the Entrepreneurship Competition, the co-founder Lorenzo Fauvette And Thomas Sicouri I answered some questions to the outside world about how to use 3D Print the question of giving new value to plastic waste, which reads:

And 3D The origin of printing

Lorenzo and Thomas: We are architects concerned about the environment and share a passion for new technologies applied to architecture, art and design. In fact, we believe that certain technologies can significantly improve the environmental state of our manufacturing and consumption patterns. We both hold a master’s degree in Algorithmic Design, Digital Manufacturing and Robotics for the Construction Industry, from the Ecole Nationale d’Etudes Ponts in France. (ENPC) got. we use 3D Printing as a prototyping tool and realizing it by making a leap of scale,3D Printing has the potential to be disruptive in many areas.

△LaurentYes POOL One of the founders: He was in Startup Competition 3D PrintParis 2022 The startup is presented on (Image source:3D printing)

POOL The establishment of

Lorenzo and Thomas: POOL is to listen to usENPCIt was based on the professor’s suggestion. We both wanted to start a business and we realized XL 3D Model Printing has enormous potential in art and architecture. In addition to new design and manufacturing approaches, we have chosen to take advantage3D The flexibility and compactness of printing make it a tool for recovering plastics. That’s how we started. We started to think about using XL 3D Model Printing system to test mass recycling and/or biosourced materials.POOL This is how by using plastic waste as 3D The idea of printing raw materials was born.

POOL The name comes from a play on non-circular words based on our concept of circular economy:PLASTIC BUCKLE——Written backwards POOL-P…just like the circular economy. In French it’s pronounced like “animal”octopus“, it can transform, change color and shape, just like 3D Same as printed.

△The name of this startup is based on the concept of circular economy (Image source:black13kira)

POOLurban micro-factories andXXLprinting technology

Lorenzo and Thomas: Today, the city is experiencing growing economic activity linked to crafts and local production, giving way to bars, restaurants and housing. Urban micro-factories are therefore designed as a compact way to settle within dense urban structures, to revitalize local economies and initiatives and to create synergies between the different players in the circular economy sector. Recyclers and industrialists of raw materials, craftsmen of project development/Designers, and finally citizens as end users.

We envision our urban micro-factory as a production tool operating in an almost closed loop, capable of recycling local plastic waste generated on its territory. Each micro-factory will be made up of multiple additive manufacturing units capable of transforming our waste into products with high aesthetic, social and environmental value.

POOLIt is hoped that through this micro-factory, another concept of production and consumption will be promoted. The idea is to use waste generated by citizens or industry in a specific area and transform it into products with high social, aesthetic and environmental value. It is therefore a question of developing both functional uses and works of art which, we hope, will change the way we look at waste and give it value through production tools capable of to produce an infinite variety of shapes. This is why we plan to develop a real network in France once our first urban micro-factories are operational and profitable.

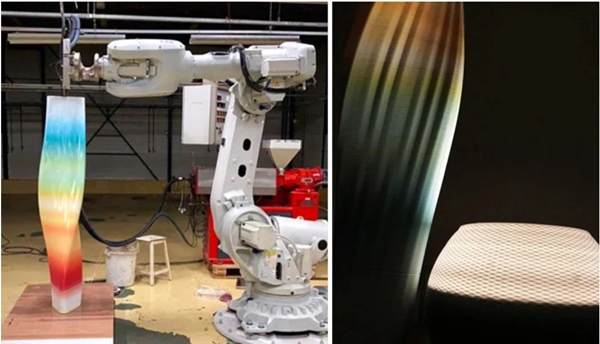

Develop a system that is easily reproducible and capable of processing the widest range of thermoplastic waste 3D printing technology, and in line with our environmental commitment, we have modernized and assembled previously used industrial machines to create robotic additive manufacturing units capable of manufacturing large objects from plastic waste.

Our printing system usesFGM(molten pellet casting), which means it is capable of printing directly from plastic pellets and grains rather than others FDM/FFF This prints by depositing metal filaments. This allows us to shorten production times, significantly reduce raw material costs and use and experiment with a variety of materials.

△Image source:POOL

Our additive manufacturing cell consists of an extruder into which the crushed material is introduced and a 6 axis ABB IRB6700 By moving the print head on the robot, it is able to convert more or less complex virtual geometries into real objects with precision and speed.

To create the first prototype of our additive manufacturing cell, given the high investment costs, we managed to establish partnerships with institutions and private companies who believed in the project. For this, we would like to thank those who have supported and helped us since the beginning. CNAM Paris、ABB Robotics France And SUEZ’s Home to Bounce Back。

types of plastic recycling andPOOL 5 Development next year

Lorenzo and Thomas: POOL Founded in 2021 Year 7 month, we are 2022 Year 3 Development of the printing system was launched in September. We are therefore still in the R&D phase and have not yet explored the full potential and possibilities of this system.

We are currently able to process post-consumer plastic waste and recycle it into more transparent plastics, such as polypropylene food containers or polyethylene bottle caps. We also process post-industrial waste from the food or pharmaceutical packaging industry. We recycle manufacturing scrap that is not directly reintroduced into the production cycle by the manufacturer.

During the manufacturing process, we do not introduce any additives or fillers to stabilize the material. This is important because all of our products can be recycled in existing recycling channels in Europe. We minimize all issues related to material behavior such as shrinkage, warping, etc. by adjusting the print settings.

In five years, we hope to be able to process a wider range of waste, not only plastic, but also organic and other, and hope to open several micro-factories in Paris and other major strategic cities.Laurent He also wanted to export this concept and create one in Rome, the city where he grew up.

△POOLof 3D Example of print structure (Image source:POOL)

POOLproducts and target markets

Lorenzo and Thomas: Currently, we mainly design and produce design and furnishing products such as stools, coffee tables, flower pots and lighting fixtures. We recently met an artist Nicolas Viallard Collaboration, we worked with him to create a 70×70 Centimeter sculpture in Paris 3D Exhibited at the print exhibition. Our products gain value not only as an object, but also as a declaration of a paradigm shift towards a new philosophy of production and consumption. Currently, our products are mainly used in the design of lobbies of companies, hotels, restaurants, stores, etc. In the long term, we hope to expand the scope of our proposals.

Today, we offer our co-design and manufacturing services primarily to architects, designers and artists wishing to unleash their creativity and aware of the urgency of minimizing environmental impact and actively participating in the ecological transition.

3DHow does printing contribute to the circular economy?

Lorenzo and Thomas:3DPrinting is an ideal tool to stimulate the circular economy.3D One of the great advantages of printing is that it allows more or less complex geometries to be produced while optimizing the quantity of material used. In our case, this generates almost no manufacturing waste since we can easily reintegrate it into the production cycle. Additionally, with the help of XL 3D Model By printing, we can easily achieve just-in-time production. This means that we only produce the parts we need. There is no overproduction and therefore no unsold parts. Another great advantage is that we can recycle produced items, convert them back into raw materials and create new items.

Additionally, our microfactory system will significantly reduce transportation costs and distances by producing as close as possible and using waste generated by the region’s industry and residents.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.