2023Year4moon21On this day, according to Mohou.com,Phase3Dis a start-up that develops optical monitoring software specifically for metal additive manufacturing. This innovative solution quickly identifies print defects when they occur, helping to prevent productivity or performance degradation. at present,Phase3D The metals are explored in collaboration with the Argonne National Laboratory, which is supported and overseen by the U.S. Department of Energy.3DPrinting research to fight global warming and decarbonize manufacturing processes. Additionally, they work on metals 3D Certification challenges that printed parts can face, especially in demanding industries such as aerospace and defense.

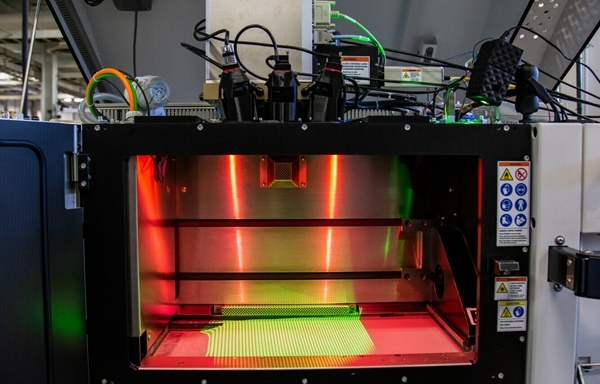

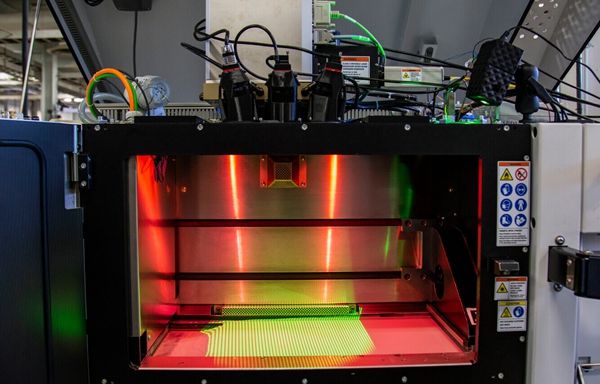

Regardless of the additive manufacturing process used, printers are likely to encounter printing defects that can seriously affect the quality, surface, properties and performance of the final product. However, continued technological advancements have led to various solutions that can help overcome these challenges. In many cases, software tools come into play during the design phase or manufacturing process to monitor and correct issues in real time. One such cutting-edge solution is Phase3Dusing structured light technology, can illuminate any 3D Non-destructive evaluation of prints, particularly for metal additive manufacturing processes.

△Installed in 3D on the printer Phase3D solution

in short,Phase3D The structured light used measures the height of each layer deposited, allowing it to quickly detect possible defects and stop production if necessary. The solution is currently compatible with powder bed fusion and powder bonding processes, including ExOne machines andEOS M290printer.Phase3D Founder and CEO Niall O’Dowd The doctor said: “In 3DIn printing, there are sometimes tens of thousands of layers, and the layer thickness is sometimes as small as one-fifth the width of a human hair.Phase3DRather than using images or the relative heat of the process to detect defects, a reliable inspection system is created to verify layer height. As the standard evolves, this detection data will be important. “

Faults are detected and 3D Displayed as: Other solutions only appear in2DThe form shows that it is impossible to know exactly what needs to be adjusted. With the help of3D stage ofEnd of the project,in reality3DEnvironmental detection3DA printed situation.

●Intelligent real-time data quantified into real units: Be able to understand in real time where and when print failures are occurring and learn exactly how to resolve them with real, accurate measurements.

● Non-destructive testing, connectable to printers of all sizes: measure via non-destructive evaluation using dedicated modular structured light technology3DImpression. Ability to connect printers of any size and harness the power of intelligent real-time data for faster speeds, greater accuracy and high inspection efficiency.

●Phase3D with leading materials scientist at Argonne National Laboratory Xuan Zhang By working closely together, the effectiveness of their solutions is tested. During the research, technicians deliberately introduced defects into the metal printing process while adhering to strict safety standards to determine whether the proposed solution worked. Through rigorous testing,Phase3D aims to improve its technology and provide metal 3D Print provides high quality and reliable monitoring solutions.

△Niall O’Dowd Doctor and Zhang Xuan

Niall O’Dowd The doctor concluded: “In random structures, pores with a size of only a few tens of microns are sometimes printed. Without defect detection, the printer does not know if there are fluctuations or anomalies in the printing process. In this study, we deliberately introduced 20 arrive 200 Micron defects are then tested using inspection techniques. “The two partners are also working on the certification of production parts but have not revealed the methods used.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.